CaO-MgO-Al2O3-SiO2 glass encapsulating method for SiCf/SiC nuclear cladding tube port

A cao-mgo-al2o3-sio2, glass encapsulation technology, used in nuclear power generation, climate sustainability, fuel elements, etc., can solve the problem of difficult to meet the SiC core cladding tube packaging requirements, high connection temperature, unable to meet the cladding requirements The air-tightness requirements of the tube can achieve the effect of reducing internal residual stress, preventing interface cracking, and reducing the decay rate of nuclear radiation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

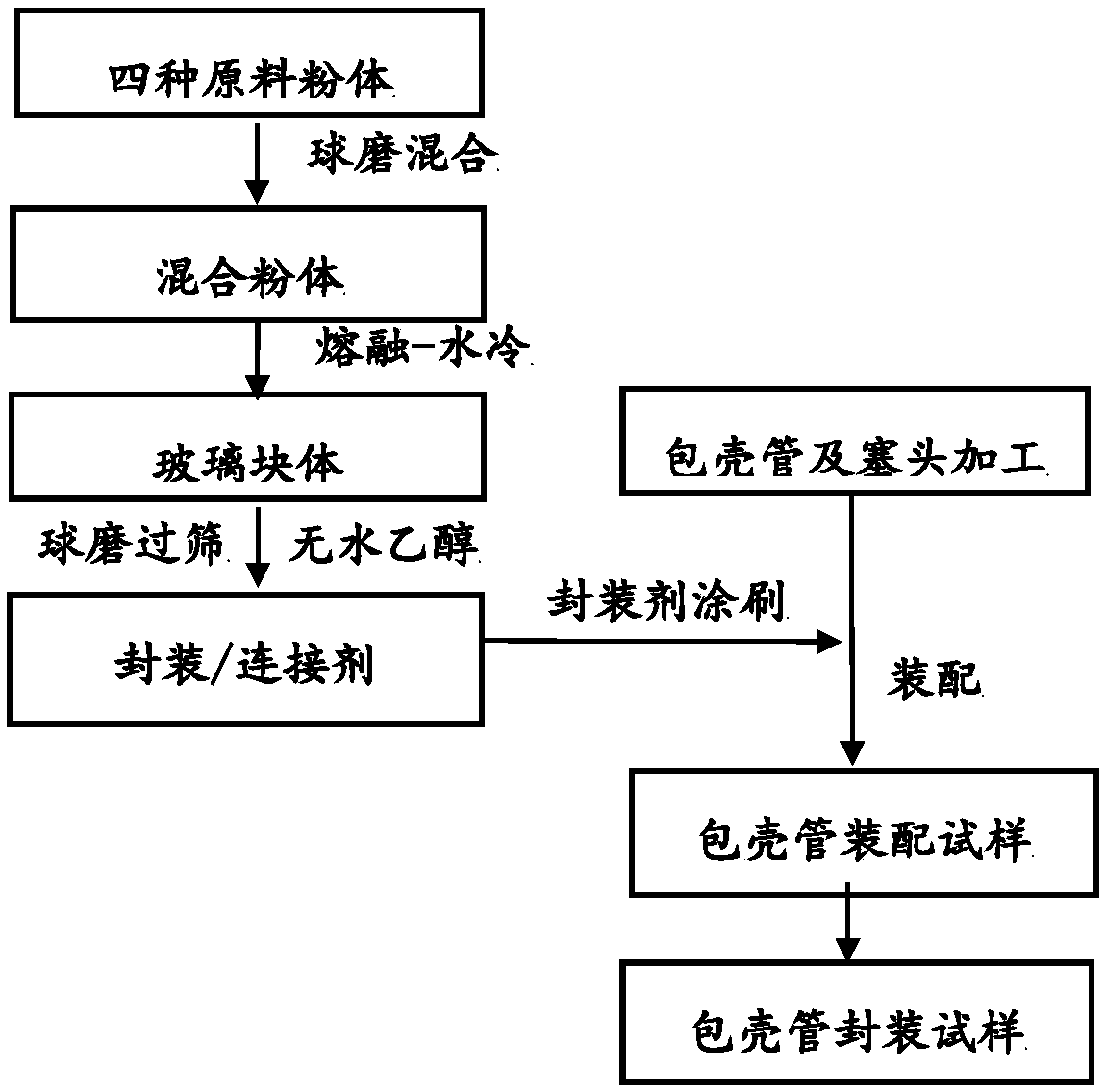

[0034] Using CaO, MgO, Al with scale ~1μm 2 O 3 , SiO 2 Four kinds of powder, the proportion of which is: 10.5wt.%CaO, 10.5wt.%MgO, 15wt.%Al 2 O 3 ,64wt.%SiO 2 , the four powders were mixed with alcohol and ball-milled for 12 hours. After mixing, the slurry was dried to make a mixed powder. The prepared mixed powder was placed in an alumina crucible, kept at 1600° C. for 2 hours in an air atmosphere, taken out and quenched in cold water to form a transparent glass block. The glass block was ball-milled in a ball-milling jar for 10 hours and passed through a 150-mesh sieve to prepare glass powder. The prepared glass powder is mixed with alcohol to form an encapsulant, wherein the mass fraction of alcohol added is 70%. The prepared encapsulant is evenly brushed on the processed SiC f / SiC plug to be encapsulated surface, and with SiC f / SiC core cladding tube is assembled, and placed in a vacuum furnace for heat treatment. The heat treatment atmosphere is vacuum, the hea...

Embodiment 2

[0036] Using CaO, MgO, Al with scale ~1μm 2 O 3 , SiO 2 Four kinds of powder, the proportion by mass is: 11wt.%CaO, 9wt.%MgO, 20wt.%Al 2 O 3 ,60wt.%SiO 2, the four powders were mixed with alcohol and ball milled for 12 hours, and the slurry was dried after mixing to make a mixed powder. The prepared mixed powder was placed in an alumina crucible, held in an air atmosphere at 1600°C for 2 hours, then taken out and quenched in cold water to form a transparent glass block. The glass block was milled for 10 h in a ball mill and passed through a 150-mesh sieve to prepare glass powder. The prepared glass powder is mixed with alcohol to form an encapsulant, wherein the mass fraction of alcohol added is 70%. Apply the prepared encapsulant evenly on the processed SiC f / SiC plug to be encapsulated surface, and with SiC f The / SiC core cladding tube is assembled and placed in a vacuum furnace for heat treatment. The heat treatment atmosphere is vacuum, the heat treatment temper...

Embodiment 3

[0038] CaO, MgO, Al with scale ~1μm 2 o 3 , SiO 2 The mass ratio of four kinds of powders is: 11wt.% CaO, 9wt.% MgO, 20wt.% Al 2 o 3 ,60wt.%SiO 2 , the four powders were mixed with alcohol and ball milled for 10 hours, and the slurry was dried after mixing to make a mixed powder. The prepared mixed powder was placed in an alumina crucible, held in an air atmosphere at 1650°C for 2 hours, then taken out and quenched in cold water to form a transparent glass block. The glass block was milled for 10 h in a ball mill and passed through a 150-mesh sieve to prepare glass powder. The prepared glass powder is mixed with alcohol to form an encapsulant, wherein the mass fraction of alcohol added is 90%. Apply the prepared encapsulant evenly on the processed SiC f / SiC plug to be encapsulated surface, and with SiC f The / SiC core cladding tube is assembled and placed in a vacuum furnace for heat treatment. The heat treatment atmosphere is vacuum, the heat treatment temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com