High-performance quick-drying waterborne UV (ultraviolet) wood coating and preparation method thereof

A wood coating, fast-drying technology, applied in the field of coatings, can solve the problems of time-consuming and energy-consuming, low drying efficiency of water-based UV coatings, etc., and achieve the effect of low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

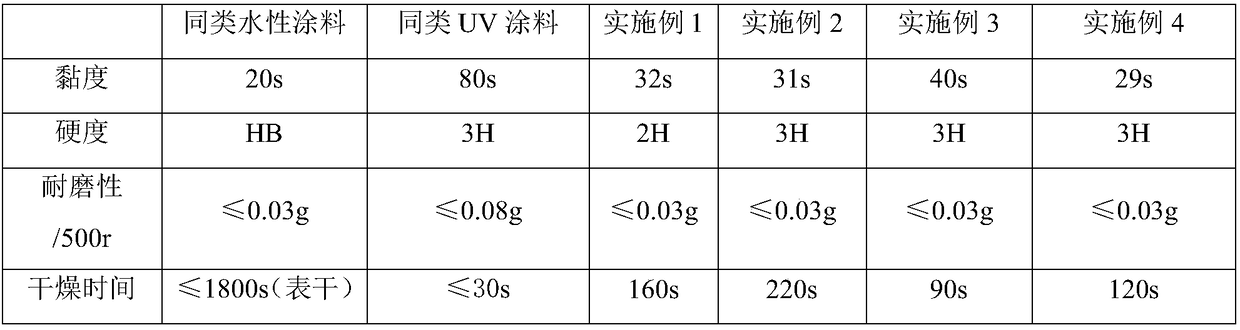

Examples

Embodiment 1

[0026] A preparation method of high-performance quick-drying water-based UV wood coating: add 44g of water to the reaction vessel, add 24g of acrylic acid, 4g of styrene, 7g of ethyl acrylate in turn, stir at 150r / min, add 8g of ammonium persulfate solution (mass concentration is 10%). Then, 96 g of remaining acrylic acid, 16 g of styrene, and 103 g of ethyl acrylate were added dropwise within 70-90 min. Add dropwise the remaining ammonium persulfate solution (mass concentration: 10%) 32g and KH550 36g within 90-110min. After the dropwise addition, adjust the temperature to 85 degrees Celsius and keep it warm for 4 hours. After the reaction is completed, filter to obtain an acrylic resin emulsion. After the resin emulsion is cooled, add 2% defoamer relative to the mass of the resin and 0.2% photoinitiator relative to the mass of the resin, 7 g of high-hardness water-soluble polyurethane powder, and stir for 10 min at a speed of 100 r / min.

Embodiment 2

[0028] A preparation method of a high-performance quick-drying water-based UV wood coating: add 96.4g of water to a reaction vessel, add 28g of acrylic acid, 4g of vinyl acetate, and 8g of butyl acrylate in turn, stir at a speed of 150r / min, and add 0.8g of persulfuric acid Ammonium solution (mass concentration is 10%). Then, 112 g of remaining acrylic acid, 16 g of styrene, and 71.6 g of ethyl acrylate were added dropwise within 70-90 min. Add the remaining ammonium persulfate solution (mass concentration: 10%) 3.2g and KH550 40g dropwise within 90-110min. After the dropwise addition, adjust the temperature to 85 degrees Celsius and keep it warm for 3 hours. After the reaction is completed, filter to obtain an acrylic resin emulsion . After the resin emulsion is cooled, add 1% defoamer relative to the mass of the resin and 0.2% photoinitiator relative to the mass of the resin, 5 g of high-hardness water-soluble polyurethane powder, and stir for 10 min at a speed of 100 r / min...

Embodiment 3

[0030] A preparation method of high-performance quick-drying water-based UV wood coating: add 8g of water to the reaction vessel, add 33g of acrylic acid, 11g of methyl acrylate, 11g of isooctyl acrylate, stir at 150r / min, add 8g of persulfuric acid Ammonium solution (mass concentration is 20%). Then, 102 g of remaining acrylic acid, 44 g of styrene, and 109 g of isooctyl acrylate were added dropwise within 70-90 min. Add 32 g of remaining ammonium persulfate (mass concentration: 20%) and 12 g of KH560 dropwise within 90-110 min. After the addition is complete, adjust the temperature to 80 degrees Celsius and keep it warm for 3 hours. After the reaction is completed, filter to obtain an acrylic resin emulsion. After the resin emulsion is cooled, add 4% defoamer relative to the mass of the resin, 0.4% photoinitiator relative to the mass of the resin, 7g of high-hardness water-soluble polyurethane powder, and stir at 100r / min for 10min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com