Environment-friendly anti-static electronic wafer protective film and preparation method thereof

An antistatic and environmentally friendly technology, used in static electricity, electrical components, conductive adhesives, etc., can solve the problem of high temperature resistance, achieve the effect of good initial focus, reduce loss costs, and reduce the discharge of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

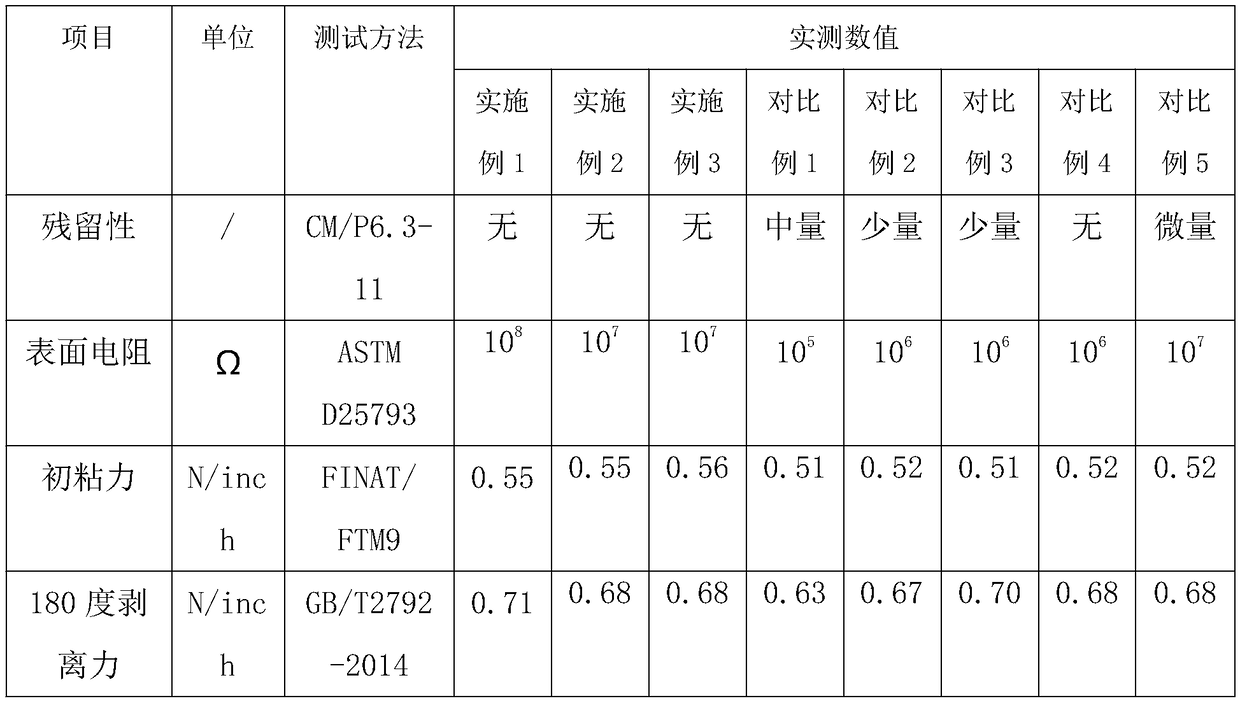

Examples

Embodiment 1

[0017] An environment-friendly antistatic electronic wafer protection film is characterized in that: it includes a polyurethane film and a glue layer; the raw materials of the glue layer include acrylic pressure-sensitive adhesive and an ion compounded liquid; the ion compounded liquid contains an imidazole functional group The ionic liquid and LiTFSi; the addition of the ionic compound liquid is 1% by mass of the acrylic pressure-sensitive adhesive; the mass ratio of the ionic liquid containing imidazole functional groups to LiTFSi is 62.5:37.5. The ionic liquid containing imidazole functional group is prepared by synthesis of 3-dimethylimidazolium cation and BF4- anion.

[0018] A preparation method of an environment-friendly antistatic electronic wafer protective film, characterized in that it comprises the following steps:

[0019] (1) Pour the acrylic pressure-sensitive adhesive into a blender, add 1% antistatic ionic liquid containing imidazole functional group and LiTFS...

Embodiment 2

[0023] An environment-friendly antistatic electronic wafer protection film is characterized in that: it includes a polyurethane film and a glue layer; the raw materials of the glue layer include acrylic pressure-sensitive adhesive and an ion compounded liquid; the ion compounded liquid contains an imidazole functional group The ionic liquid and LiTFSi; the addition of the ionic compound liquid is 0.5% by mass of the acrylic pressure-sensitive adhesive; the mass ratio of the ionic liquid containing imidazole functional groups to LiTFSi is 60:40. The ionic liquid containing imidazole functional group is prepared by synthesis of 3-dimethylimidazolium cation and BF4- anion.

[0024] A preparation method of an environment-friendly antistatic electronic wafer protective film, characterized in that it comprises the following steps:

[0025] (1) Pour the acrylic pressure-sensitive adhesive into the mixer, add 0.5% antistatic ionic liquid containing imidazole functional group and LiTFS...

Embodiment 3

[0029] An environment-friendly antistatic electronic wafer protection film is characterized in that: it includes a polyurethane film and a glue layer; the raw materials of the glue layer include acrylic pressure-sensitive adhesive and an ion compounded liquid; the ion compounded liquid contains an imidazole functional group The ionic liquid and LiTFSi; the addition of the ionic compound liquid is 2% by mass of the acrylic pressure-sensitive adhesive; the mass ratio of the ionic liquid containing imidazole functional groups to LiTFSi is 65:35. The ionic liquid containing imidazole functional group is prepared by synthesis of 3-dimethylimidazolium cation and BF4- anion.

[0030] A preparation method of an environment-friendly antistatic electronic wafer protective film, characterized in that it comprises the following steps:

[0031] (1) Pour the acrylic pressure-sensitive adhesive into a blender, add 2% antistatic ionic liquid containing imidazole functional group and LiTFSi co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com