Waste treatment system and process in waste plastics regenerated diesel oil production process

A technology for regenerating diesel oil and production process, applied to the chemical industry, can solve the problems of substandard quality and environmental protection, secondary pollution of resources, poor product performance, etc., and achieve the effects of good continuity, high conversion rate and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

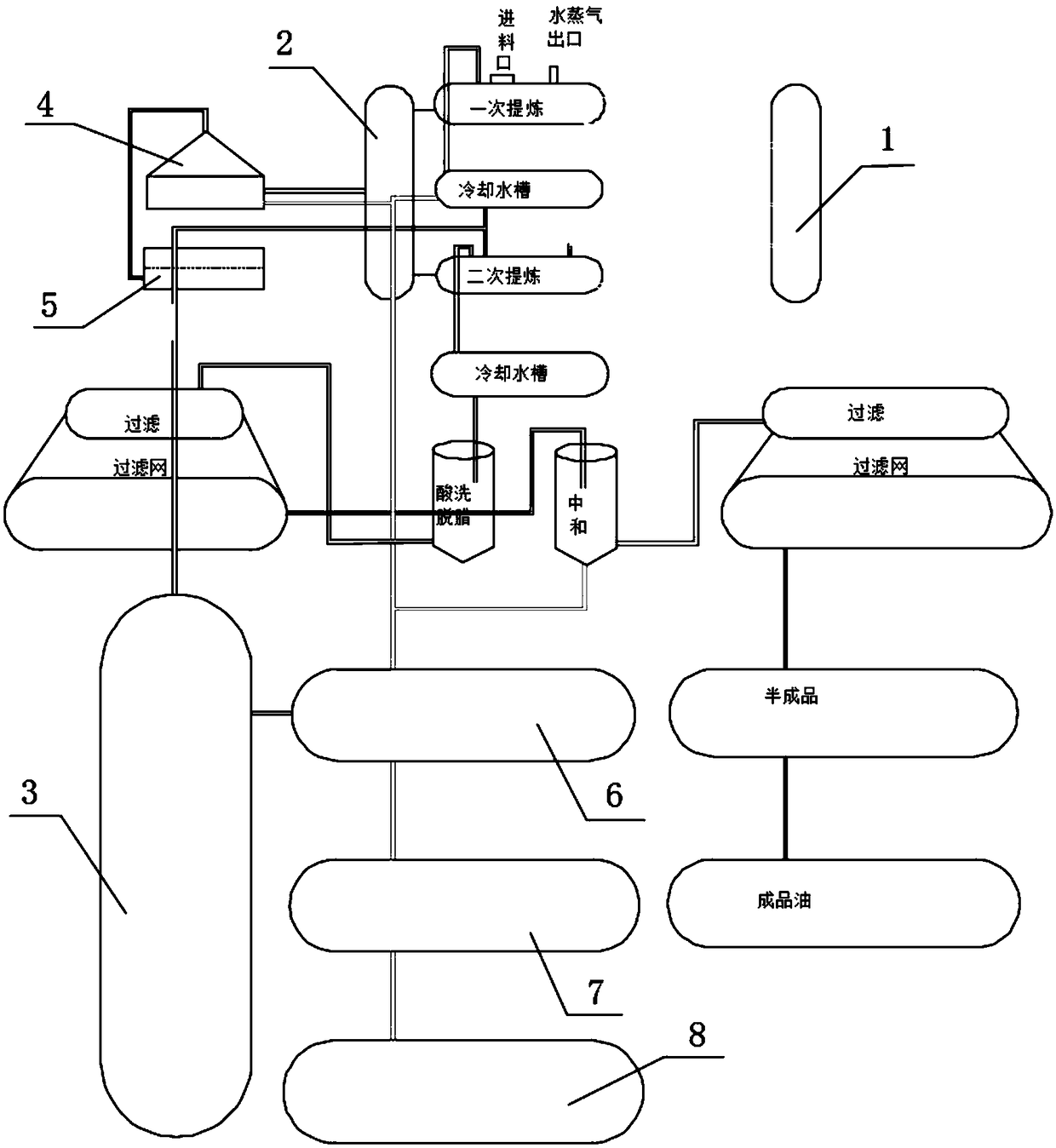

[0017] For the overall composition of the system in the embodiment of the present invention, please refer to figure 1 , consisting of a gas component collection box 1, an exhaust gas collection tank 2, and an oil-water separation 6. The gas component collection box is connected with the refining device used for waste plastic recycled diesel production through a gas pipeline, and the temperature of the primary refining and secondary refining boilers during production is set at The extract produced when the temperature is below 130 degrees Celsius, the extract includes natural gas and gasoline components, the gas is collected in the gas component collection box for recovery, and then enters the combustion stove for primary and secondary refining as fuel; the tail gas absorption system includes tail gas absorption tank 2, water Filtration device 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com