Copper alloy for electronic and electrical equipment and application

An electronic, electrical, copper alloy technology, applied to the field of alloys, can solve the problems of inability to meet the requirements of miniaturization, lightweight electronic and electrical components, insufficient comprehensive performance of brass, etc., to reduce material costs, balance bending performance, and improve materials. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

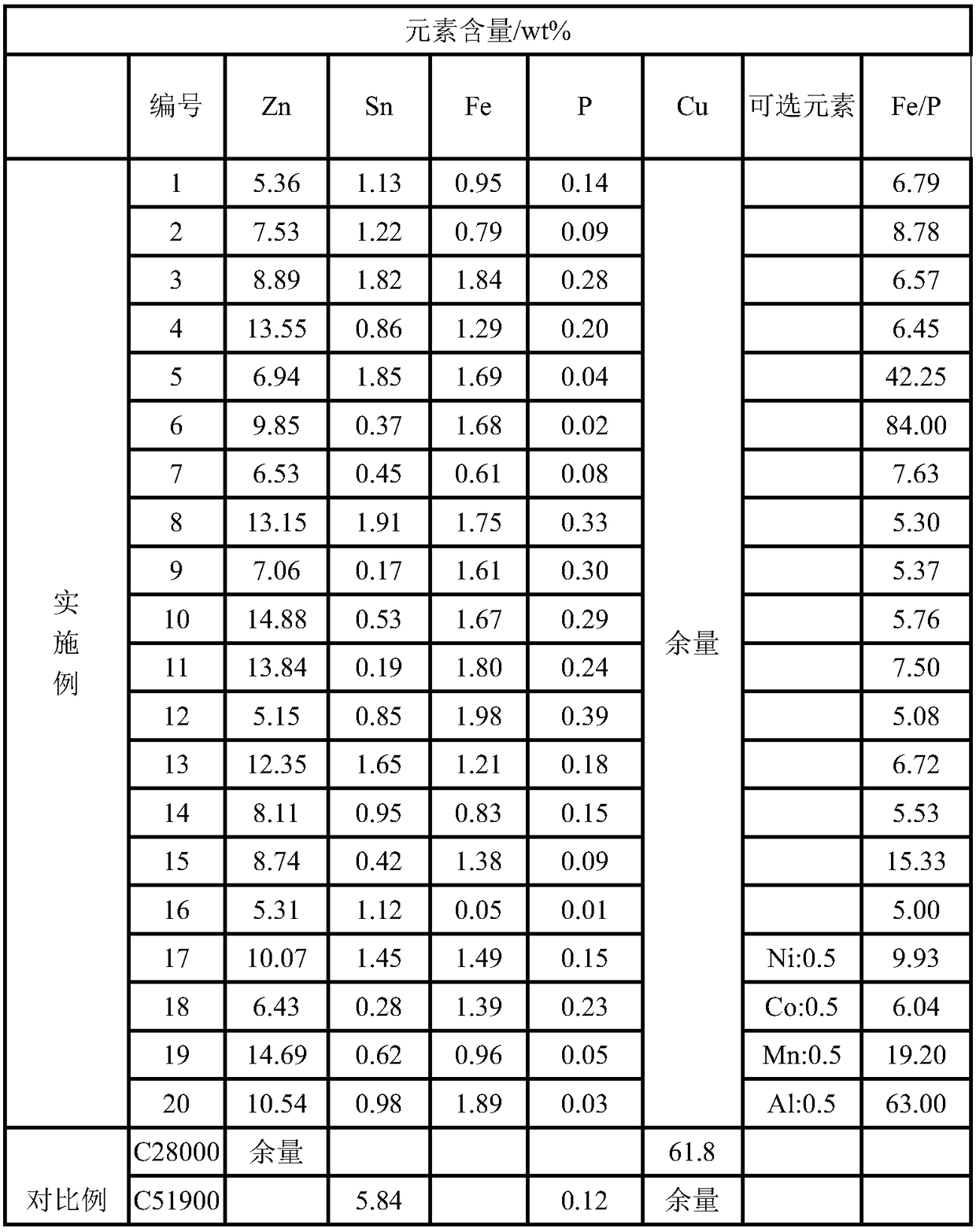

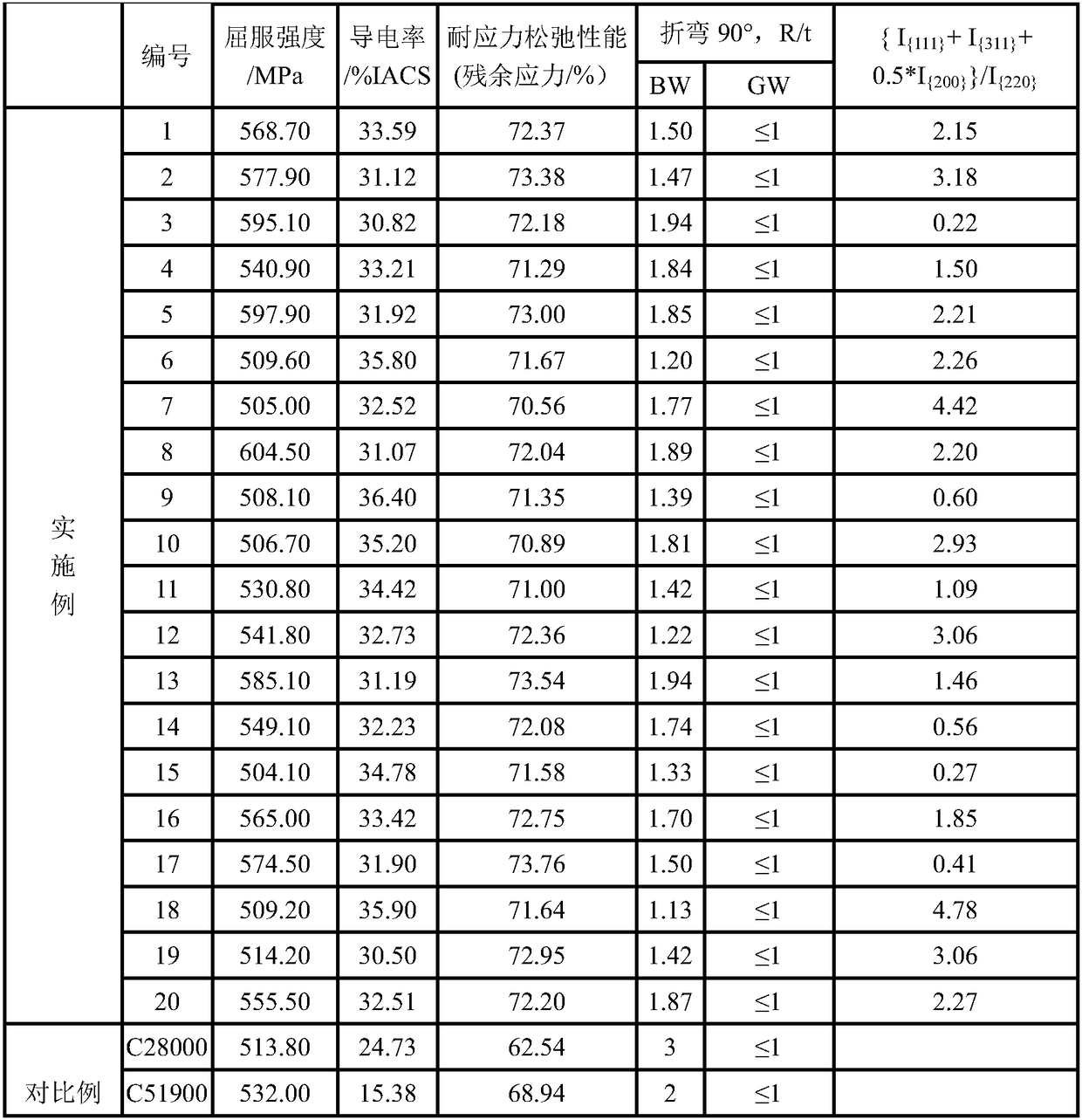

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0041] According to the ingredients in Table 1, melting was carried out at 1150° C. to manufacture an ingot with a size of 170mm×320mm. After the above ingot was kept at 850°C for 5 hours, hot rolling was carried out to make the plate thickness reach 16.5mm; then, face milling was carried out to make the thickness reach 15mm, and a plate with a thickness of 2mm was passed through one cold rolling; The rolled plate is heated to 440°C and kept at 8h for the first aging; the material after the first aging is subjected to the second cold rolling to 0.35mm, and then the second aging is carried out at 400°C for 8h Treatment; finally, finish cold rolling, that is, three times of cold rolling, with a rolling target plate thickness of 0.2 mm; after finish cold rolling, heat preservation at 210° C. for 4 hours for low-temperature annealing to obtain a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com