Nickel alloy base strip with cubic texture, and preparation method thereof

A technology of cubic texture and nickel alloy is applied in the field of cubic texture nickel alloy base tape and its preparation, which can solve the problems of complex preparation method, industrialized production defects, limiting the wide application of coated superconducting materials, etc., and achieves high yield strength. , the effect of promoting nucleation and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The steps of the preparation method of the embodiment of the present invention 1 are as follows:

[0019] Vacuum induction melting is used to obtain nickel alloy ingots with tungsten and carbon atomic percentages of 9.5% and 0.006%, respectively, and initial alloy ingots are obtained by forging and hot rolling;

[0020] Remove the oxide skin from the initial alloy ingot obtained above and then cold-roll it to a thickness of 35 μm, with a total deformation of 98%, to obtain a nickel alloy cold-rolled base strip;

[0021] The cold-rolled alloy base strip obtained above is subjected to recrystallization heat treatment to obtain a nickel alloy base strip with strong cubic texture. The recrystallization heat treatment process is: 1100°C for 2 hours, the heating rate is 5°C / min, and the annealing atmosphere is pure hydrogen.

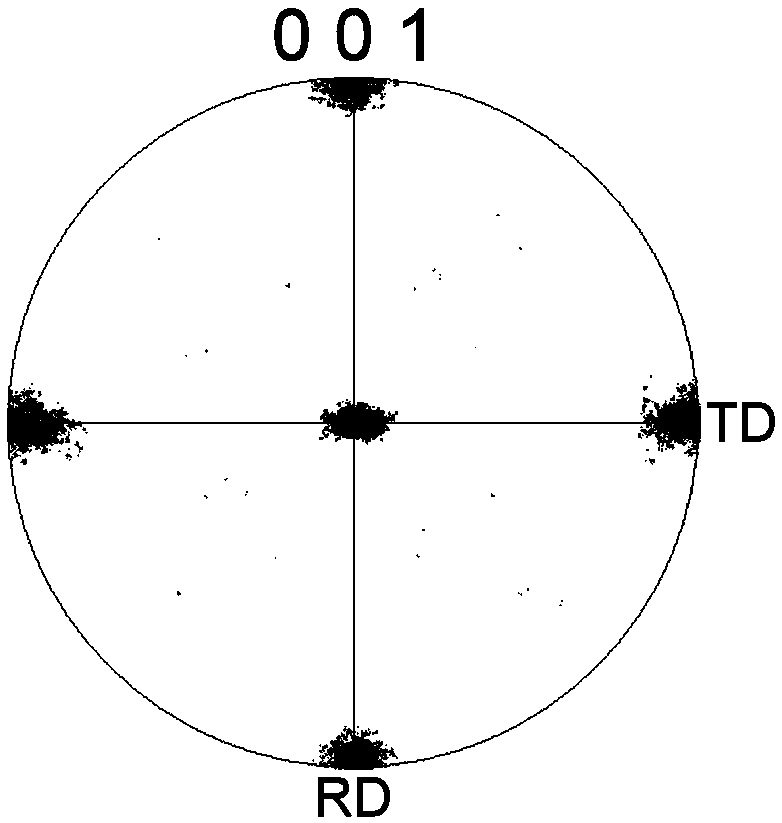

[0022] The obtained alloy base strip has no ferromagnetism as a whole, and has high yield strength. The (001) surface pole figure of the surface is as ...

Embodiment 2

[0024] The steps of the preparation method of the embodiment of the present invention 2 are as follows:

[0025] Vacuum induction melting is used to obtain nickel alloy ingots with tungsten and carbon atomic percentages of 9.5% and 0.009%, respectively, and initial alloy ingots are obtained by forging and hot rolling;

[0026] Remove the oxide skin from the initial alloy ingot obtained above and then cold-roll it to a thickness of 35 μm, with a total deformation of 98%, to obtain a nickel alloy cold-rolled base strip;

[0027] The cold-rolled alloy base strip obtained above is subjected to recrystallization heat treatment to obtain a nickel alloy base strip with strong cubic texture. The recrystallization heat treatment process is: 1200°C for 2 hours, the heating rate is 5°C / min, and the annealing atmosphere is pure hydrogen.

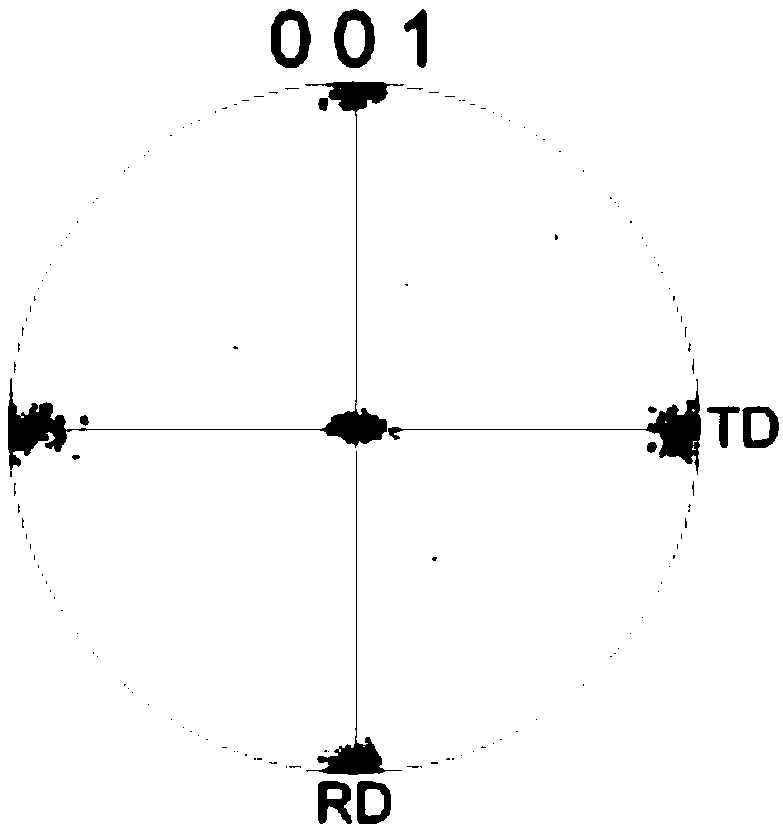

[0028] The obtained alloy base strip has no ferromagnetism as a whole, and has high yield strength. The (001) surface pole figure of the surface is as ...

Embodiment 3

[0030] The steps of the preparation method of the embodiment of the present invention 3 are as follows:

[0031] Vacuum induction melting is used to obtain nickel alloy ingots with tungsten and carbon atomic percentages of 9.5% and 0.008%, respectively, and initial alloy ingots are obtained by forging and hot rolling;

[0032] Remove the oxide skin from the initial alloy ingot obtained above and then cold-roll it to a thickness of 40 μm, with a total deformation of 98%, to obtain a nickel alloy cold-rolled base strip;

[0033] The cold-rolled alloy base strip obtained above is subjected to recrystallization heat treatment to obtain a nickel alloy base strip with strong cubic texture. The recrystallization heat treatment process is: 1100°C for 2.5 hours, the heating rate is 3°C / min, and the annealing atmosphere is pure hydrogen.

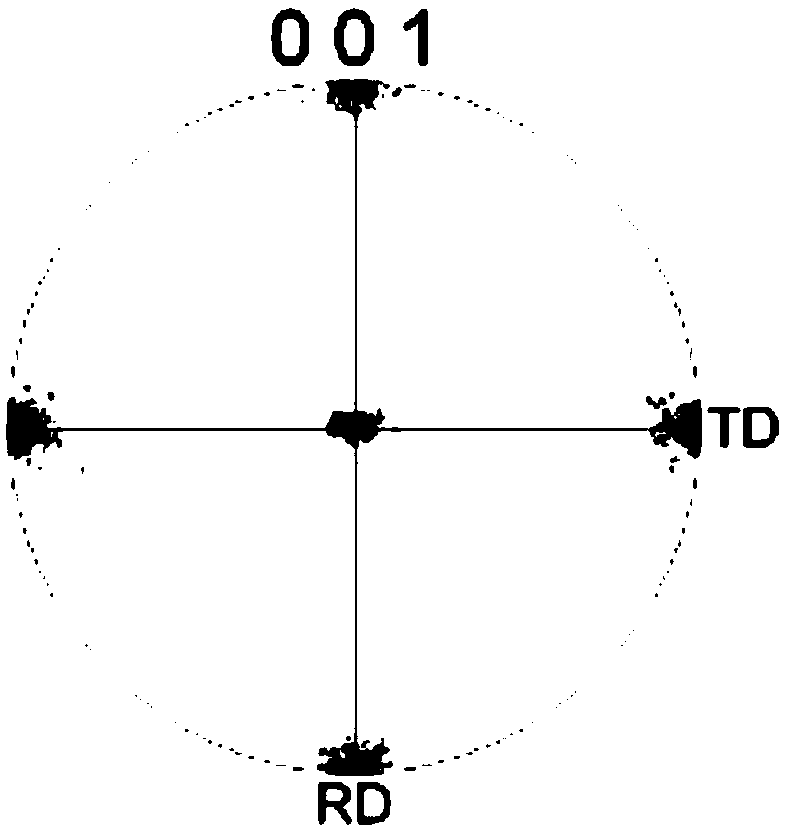

[0034] The obtained alloy base strip has no ferromagnetism as a whole, and has high yield strength. The (001) surface pole figure of the surface is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com