Method and structure for protecting electronic detonator circuit by adopting metal sleeve

A technology of electronic detonators and metal sleeves, which is applied in the direction of offensive equipment, weapon accessories, fuzes, etc., can solve the problems of internal electronic control modules that cannot normally delay ignition, blind firing of detonators, distortion and deformation, etc., to save circuit board space, Reduce the difficulty of production and reduce the effect of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

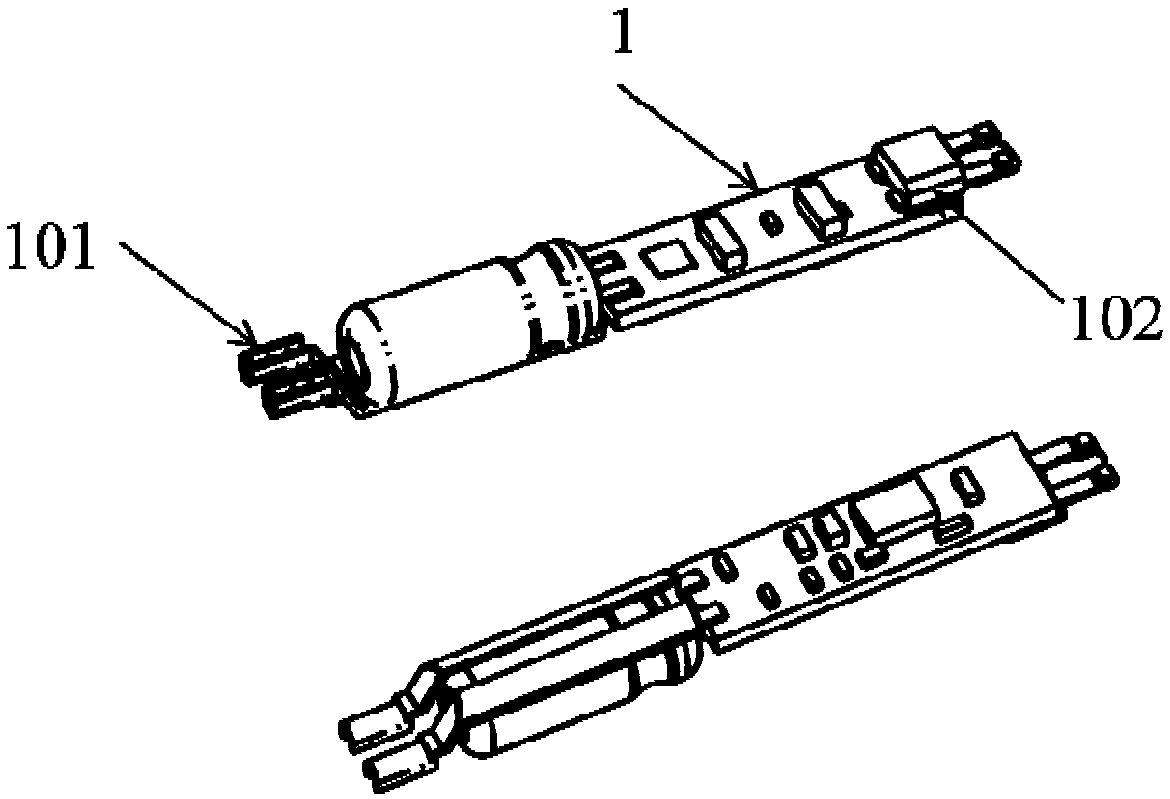

[0033] as attached figure 1 It is a schematic diagram of the electronic control module without shrapnel after the electronic components are mounted, and 101 is the pin line input terminal of the electronic control module, and there are two in total. 102 is a bridge wire terminal for detonating electronic detonator, wherein 102 is completed through surface mount technology together with other electronic components, and 101 is welded to the circuit board by plug-in welding.

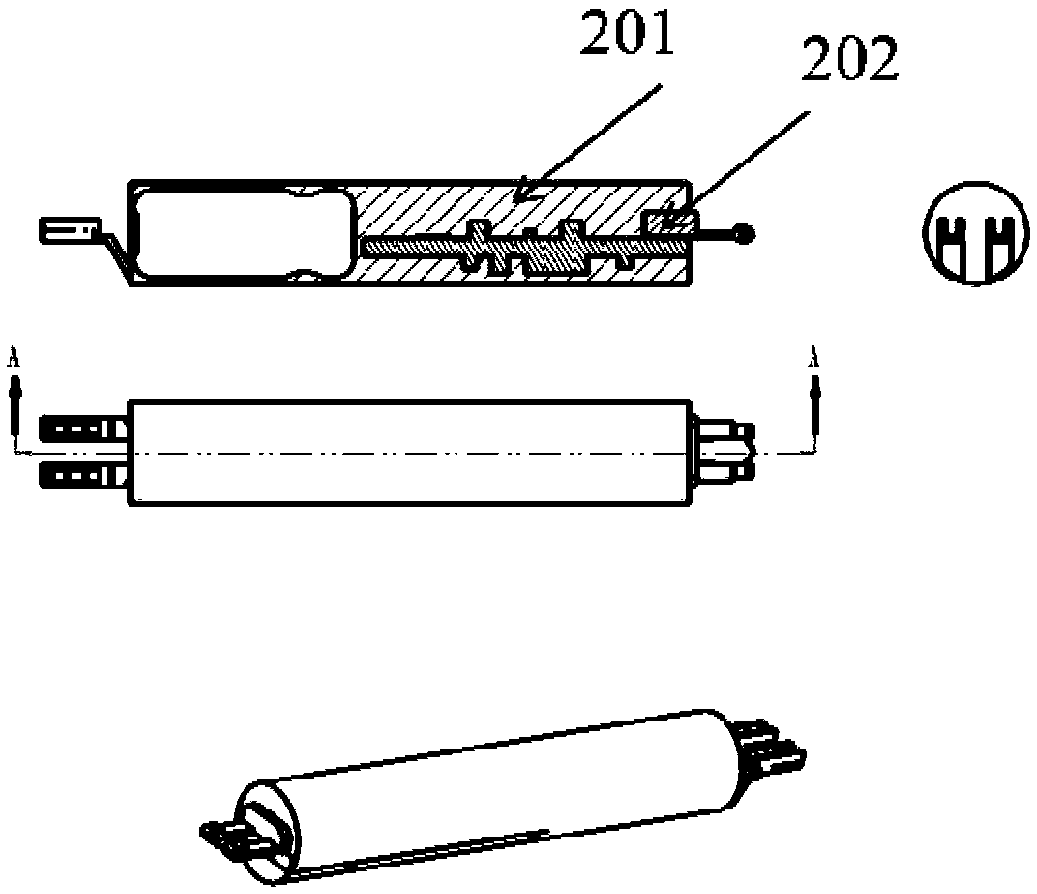

[0034] attached figure 2 It is a schematic diagram of the electronic control module without grounding shrapnel after sealing, in which 201 is the external sealing body. After all the electronic components are mounted, they are placed in a special sealing mold for low-pressure injection molding and sealing, and all the electronic components are packaged into one A regular cylinder, 202 is a circuit board part.

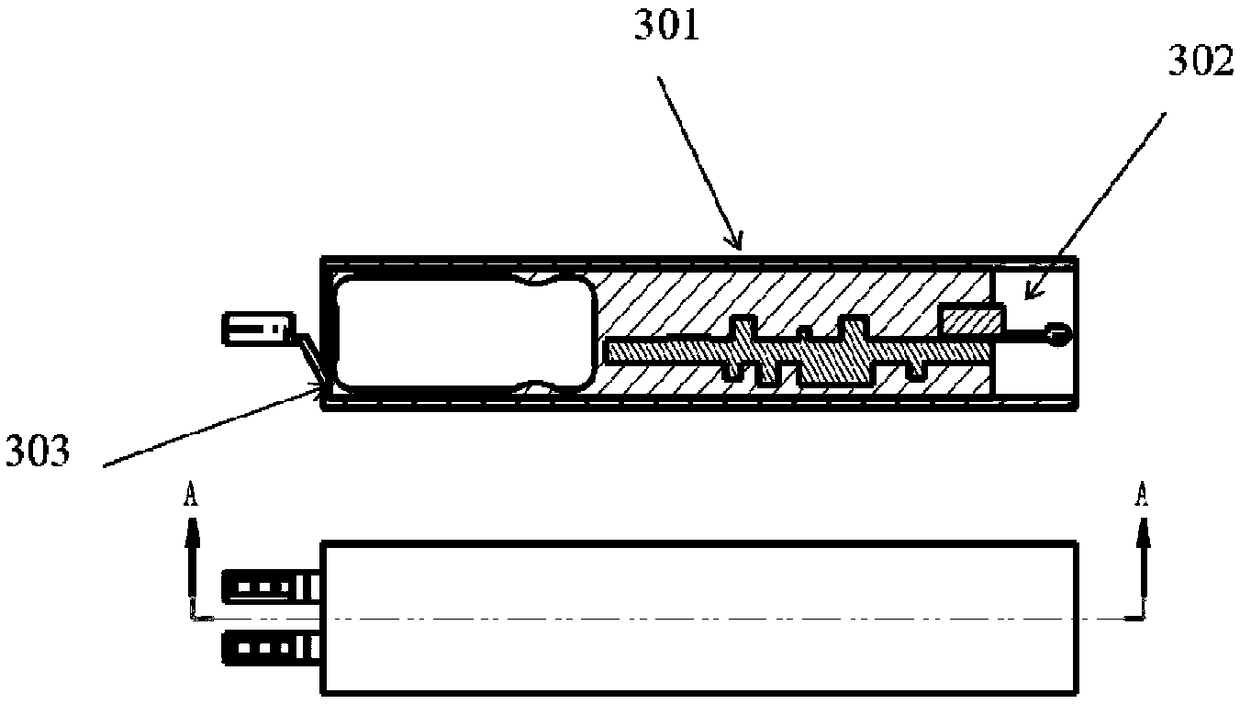

[0035] as attached image 3As shown, the sealed electronic control module is put into the met...

Embodiment 2

[0037] as attached Figure 4 Shown is a product schematic diagram of the electronic control module with grounding shrapnel after the components are mounted, and the implementation of component production is consistent with the embodiment 1 mentioned in the present invention. 401 is the grounding shrapnel, wherein the grounding shrapnel 401 is connected through the contact piece 402 and the inner wall of the metal sleeve. The grounding shrapnel 401 is connected to the circuit board 1 through the connection point B 403, which is completed by welding. The chip capacitor 404 and the chip resistor 405 is installed on the circuit board 1 through surface mount technology, and is connected in series with the ground spring 401. When the sealant 201 encapsulates the circuit board 202, the contact piece 402 leaks out, that is, the ground spring 401 is connected to the inner wall of the metal casing through the contact piece 402. At the same time, it is introduced into the circuit board a...

Embodiment 3

[0041] For the high-density SIP packaging structure, as another technical solution to install the independent control module into the electronic control module, the specific implementation is as follows:

[0042] as attached Figure 7 As shown, the main control chip chip 704, the chip capacitor A 702 and the chip capacitor 703, the chip resistor A 705, and the diode chip 706 are installed on the substrate 701; the chip capacitor A 702 and the chip capacitor 703 are attached. The chip resistor A 705 is installed on the substrate 701 by surface mount technology, and then the main control chip wafer 704 and the diode wafer 706 are fixed on the substrate 701, and then bonded and wired to connect the wafer and the circuit on the substrate 701 connect.

[0043] attached Figure 8 It is a schematic diagram after the overall SIP package is completed, 801 is the leaking pad after the package is completed, 802 is the plastic filler outside the package, and the SIP package is soldered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com