Measuring Method and System for Temperature Deformation of Piezoelectric Composite Materials

A piezoelectric composite material and testing method technology, applied in measurement devices, instruments, optical devices, etc., to achieve the effect of promoting design and preparation process, promoting improvement, and improving environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

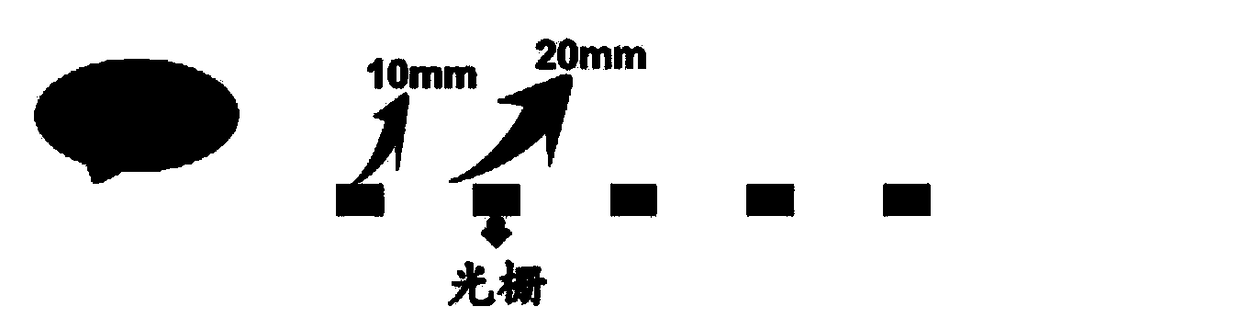

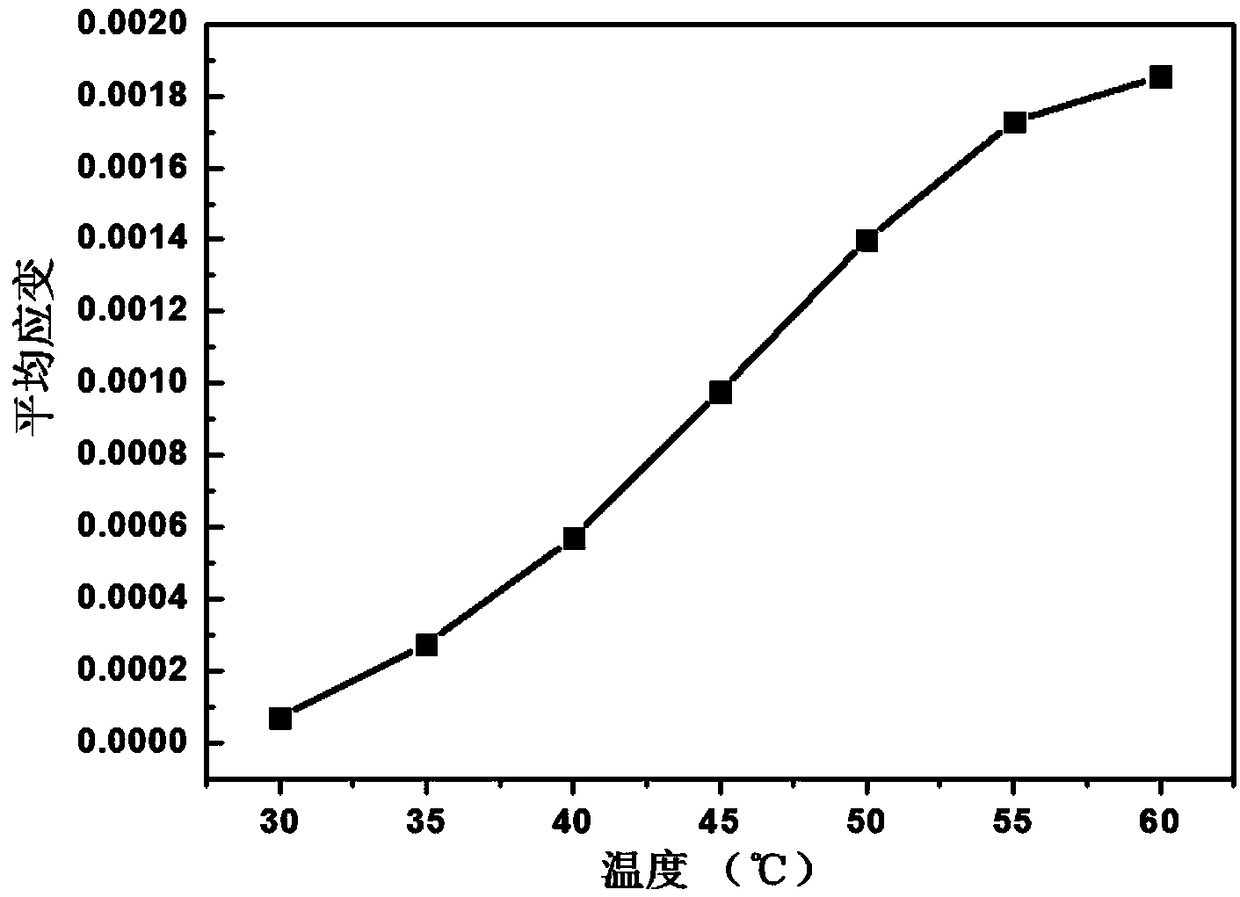

[0041] Example 1: Test method for temperature deformation of piezoelectric composite materials

[0042] A fiber grating is a diffraction grating formed by periodically modulating the refractive index of the fiber core through a certain method. The common method is to use the photosensitivity of the optical fiber material to write the coherent field pattern of the incident light into the fiber core by means of ultraviolet light exposure, and produce a periodic change in the refractive index along the axis of the fiber core in the fiber core, thereby forming a permanent space. Phase grating, its function is to form a narrow-band (transmission or reflection) filter or mirror in the fiber core.

[0043] The relationship between the wavelength change of the fiber grating reflected light and the strain is as follows:

[0044]

[0045] Among them, λ is the wavelength of the light reflected by the FBG, Δλ is the wavelength change of the light reflected by the FBG, ε is the axial str...

Embodiment 2

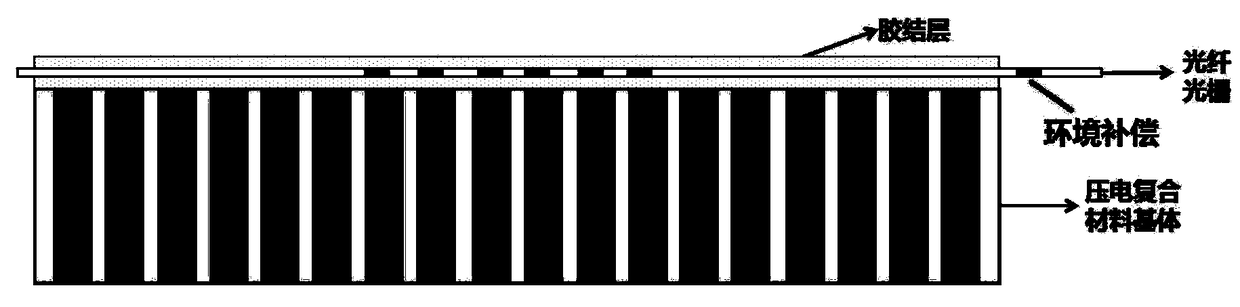

[0059] Example 2: Testing System for Temperature Deformation of Piezoelectric Composite Materials

[0060] This embodiment provides a test system for temperature deformation of piezoelectric composite materials using the above method. The composition and connection relationship of the test system are as follows: Figure 4 shown. The function description of each part is as follows:

[0061] High and low temperature test box; used to create a use environment where the temperature of the piezoelectric composite material itself rises;

[0062] Demodulator: used to monitor the wavelength of the reflected light of the fiber grating;

[0063] Impedance analyzer: used to measure performance parameters such as resonance frequency and capacitance of piezoelectric composite materials;

[0064] Computer: It is used to calculate, analyze and process the test data obtained by the demodulator and impedance analyzer, and obtain the strain value and deformation value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com