A nitrogen-doped porous carbon catalyst prepared from potatoes and its preparation and application

A technology of nitrogen-doped porous carbon and nitrogen-doped carbon, which is applied in the field of materials science, can solve the problems of ORR electrocatalytic performance and stability that cannot meet the requirements, complicated preparation process, and high preparation cost, and achieve excellent ORR electrocatalytic performance and Stability, simple preparation method, effect of reducing preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

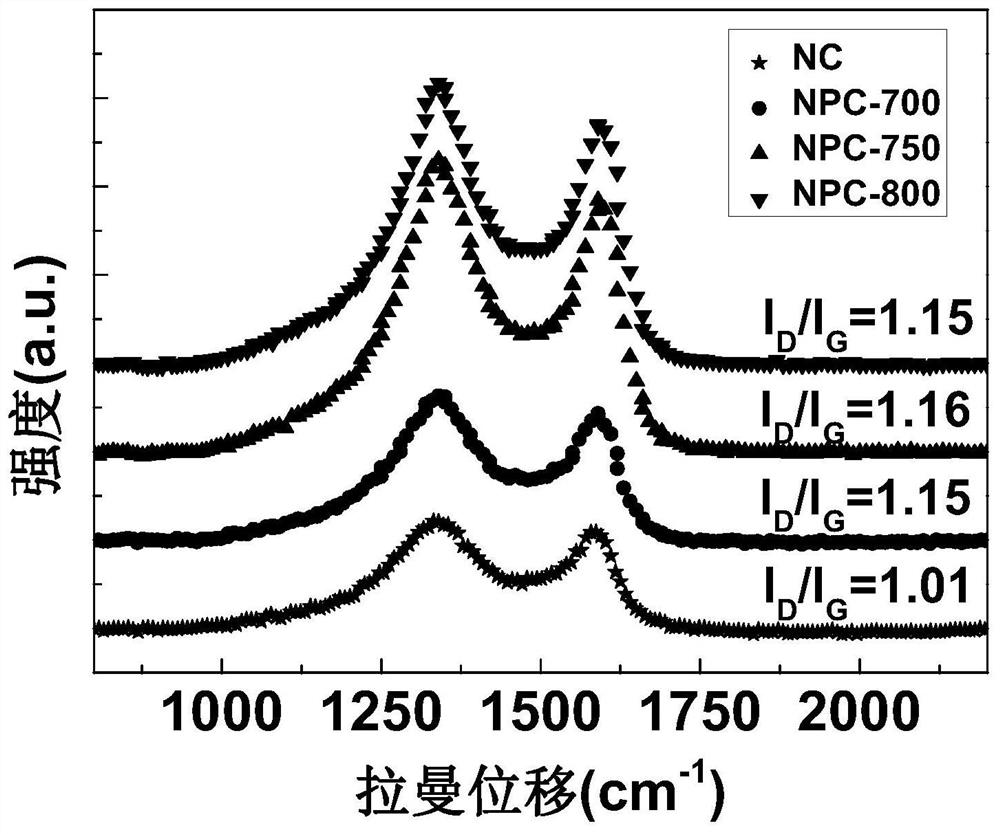

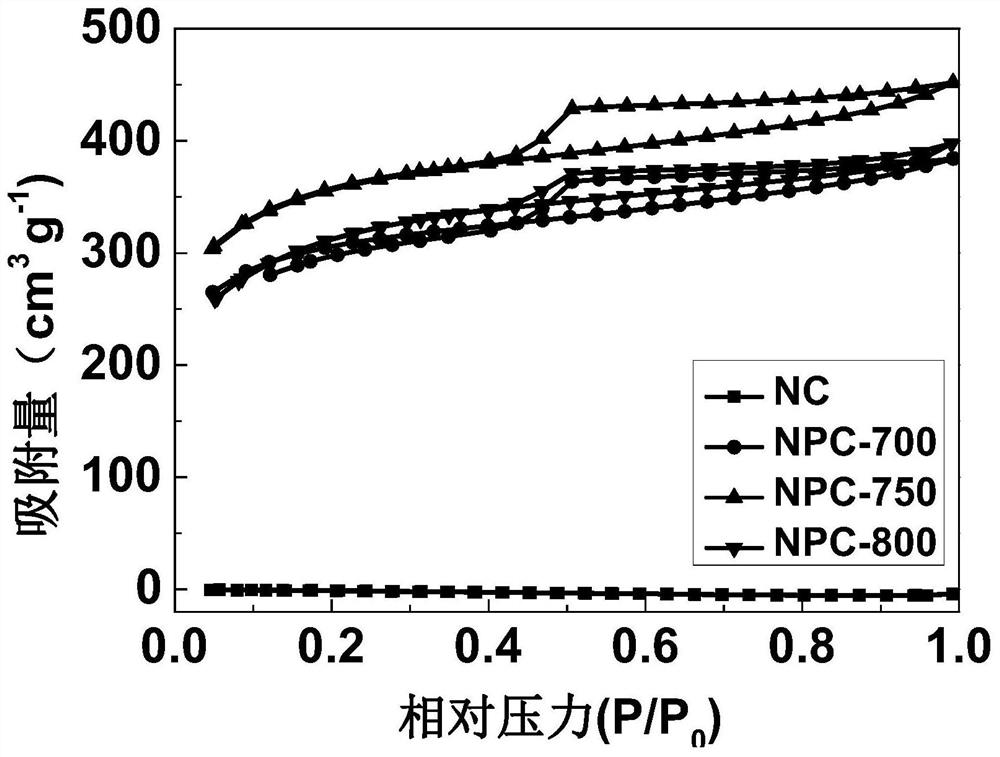

[0037] A preparation method of nitrogen-doped porous carbon ORR electrocatalyst, comprising the following steps:

[0038] In step (1), the potato precursor is boiled, ground into mashed potatoes, dried and set aside.

[0039] In step (2), the mashed potatoes dried in step (1) are transferred to a tube furnace, heated from room temperature to 900°C at a rate of 5°C / min under the protection of Ar atmosphere, and then carbonized for 2 hours to obtain nitrogen Doped carbon material (NC).

[0040] Step (3), weigh 1 gram of the carbon material obtained in step (2), add 50 ml of deionized water, stir to make it evenly dispersed; then add 3 grams of KOH, stir and dry at 80 ° C, the dried The dried intermediate was transferred to a crucible.

[0041] In step (4), the crucible in step (3) was placed in a tube furnace, under the protection of Ar atmosphere, heated from room temperature to 700°C at a rate of 3°C / min, and then activated for 1 hour.

[0042] In step (5), the activated pr...

Embodiment 2

[0044] A preparation method of nitrogen-doped porous carbon ORR electrocatalyst, comprising the following steps:

[0045] In step (1), the potato precursor is boiled, ground into mashed potatoes, dried and set aside.

[0046] In step (2), the mashed potatoes dried in step (1) are transferred to a tube furnace, heated from room temperature to 900°C at a rate of 5°C / min under the protection of Ar atmosphere, and then carbonized for 2 hours to obtain nitrogen Doped carbon material (NC).

[0047] Step (3), weigh 1 gram of the carbon material obtained in step (2), add 50 ml of deionized water, stir to make it evenly dispersed, then add 3 grams of KOH, stir and dry at 80 ° C, the dried The dried intermediate was transferred to a crucible.

[0048] In step (4), the crucible in step (3) was placed in a tube furnace, and under the protection of an Ar atmosphere, it was heated from room temperature to 750° C. at a rate of 3° C. / min, and then activated for 1 hour.

[0049]In step (5),...

Embodiment 3

[0051] A preparation method of nitrogen-doped porous carbon ORR electrocatalyst, comprising the following steps:

[0052] In step (1), the potato precursor is boiled, ground into mashed potatoes, dried and set aside.

[0053] In step (2), the mashed potatoes dried in step (1) are transferred to a tube furnace, heated from room temperature to 900°C at a rate of 5°C / min under the protection of Ar atmosphere, and then carbonized for 2 hours to obtain nitrogen Doped carbon material (NC).

[0054] Step (3), weigh 1 gram of the carbon material obtained in step (2), add 50 ml of deionized water, stir to make it evenly dispersed, then add 3 grams of KOH, stir and dry at 80 ° C, the dried The dried intermediate was transferred to a crucible.

[0055] In step (4), the crucible in step (3) was placed in a tube furnace, under the protection of Ar atmosphere, heated from room temperature to 800° C. at a rate of 3° C. / min, and then activated for 1 hour.

[0056] In step (5), the activate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com