Method for recycling metal and plastics from waste plastics containing metal cladding materials

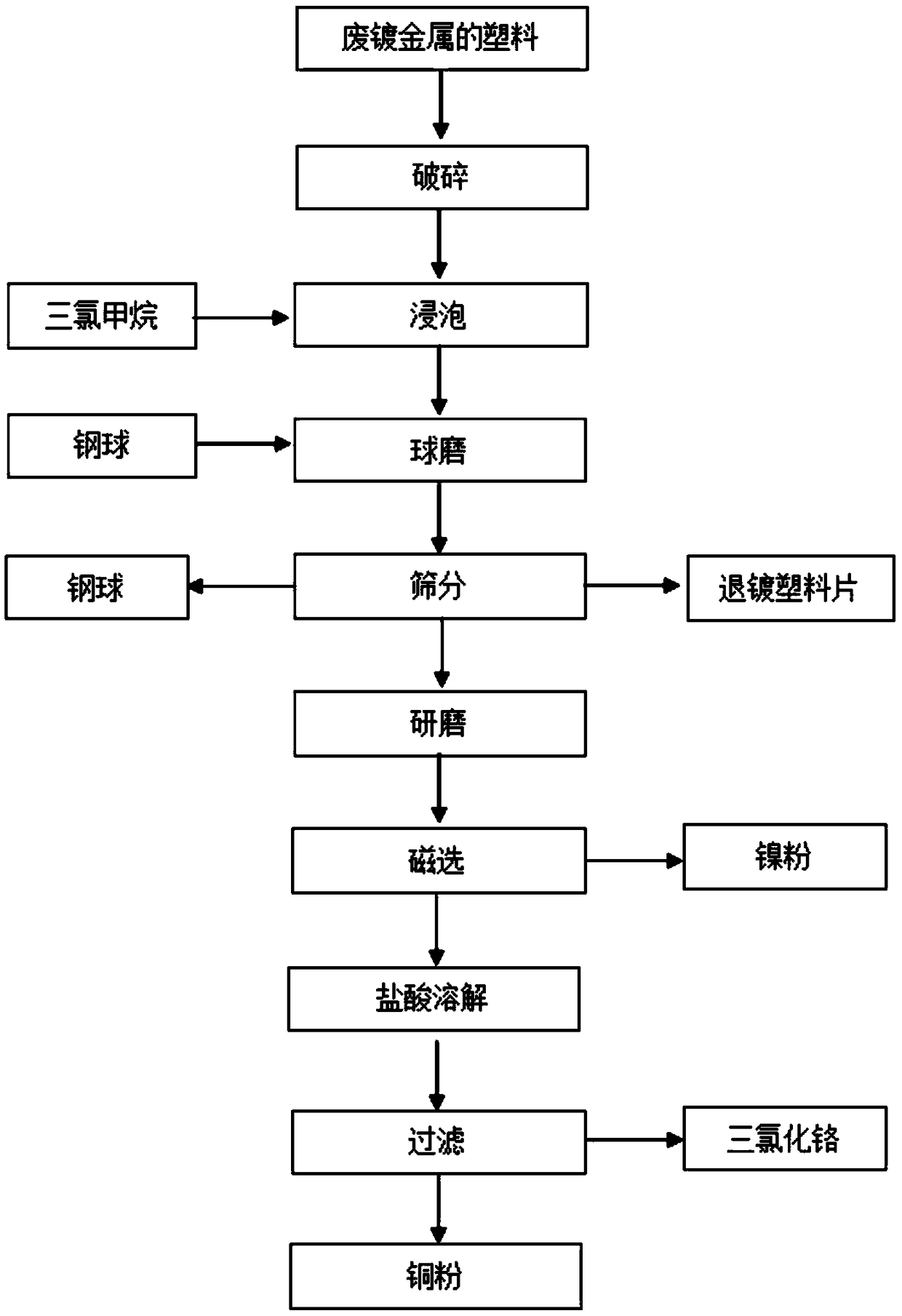

A technology of metal coating and waste plastics, applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of hidden dangers of secondary pollution, long recycling process, high processing cost, etc., achieve low cost, short recycling process, The effect of simple use of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Crushing waste plastics containing metal plating to obtain 2×2cm plastic pieces, soaking the plastic pieces in chloroform solution for 24 hours; adding 0.8Kg of plastic pieces and 1Kg of steel balls with a diameter of 30mm into a vertical stirring ball mill In the process, the whole ball mill is in a vacuum state, the system pressure is not higher than 1KPa, the rotating speed of the ball mill is 300r / min, and the ball milling process is 20-40min. The metal coating on the surface of the plastic sheet is separated from the plastic under the action of ball milling, and the metal in the metal coating is For copper, nickel and chromium, sieve to obtain metal coating and stripped plastic sheet; further grind the metal coating detached from plastic to obtain copper, nickel and chromium mixed metal powder with a particle size range of 200 mesh, and use a magnet to separate the metal The nickel is sucked out to obtain nickel, copper and chromium mixed metal powder respectively; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com