Method for preparing curdlan gum-kojic acid derivatives

A technology of kojic acid derivatives and kojic acid, which is applied in the field of antioxidants, can solve the problems of unsatisfactory modification effect of kojic acid, mild conditions, and reduced function, and achieve easy control of reaction conditions, short reaction time, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation method: (1) Mix 5g of kojic acid and 25ml of dichloromethane solvent, add 4ml of thionyl chloride dropwise while stirring at room temperature, and react for 0.5h; (2) Use petroleum After washing with ether for 2-3 times, filter to obtain kojic acid chloride, and dry it to obtain white or pink kojic acid powder; (3) Take 0.5 g curdlan gum and disperse it in 30 mL of water, then add 0.5 g of NaOH solid, stirred at room temperature for 3 hours to obtain curdlan gum-NaoH aqueous solution; (4) pour curdlan gum-NaoH aqueous solution into a three-necked flask and preheat to 60°C, and add 0.5 g of chlorinated Kojic acid solid, react for 2h; (5) Precipitate the yellow solid curdlan gum-kojic acid derivative from the solution with absolute ethanol, and then dry the extracted yellow solid curdlan gum-kojic acid derivative, then .

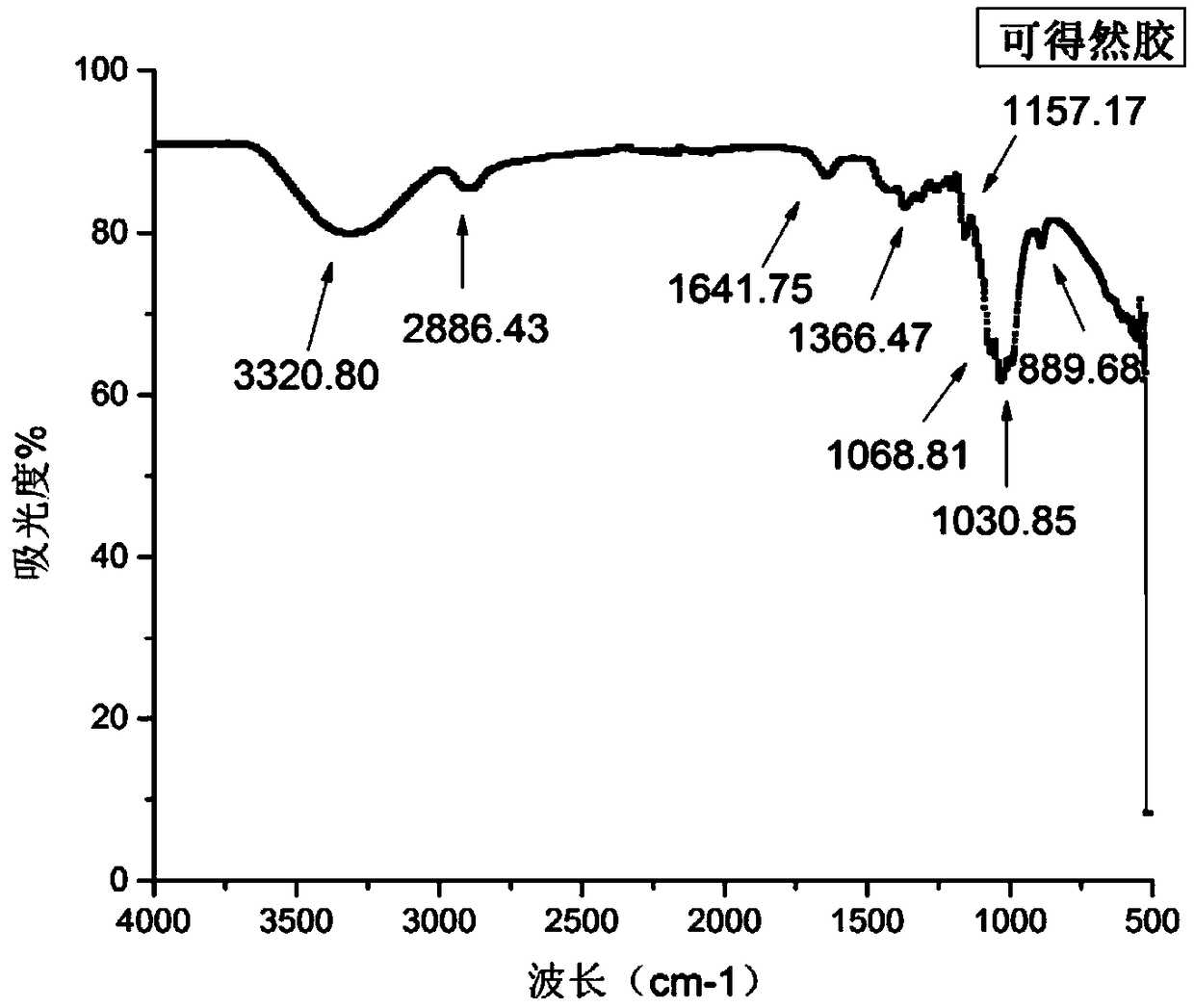

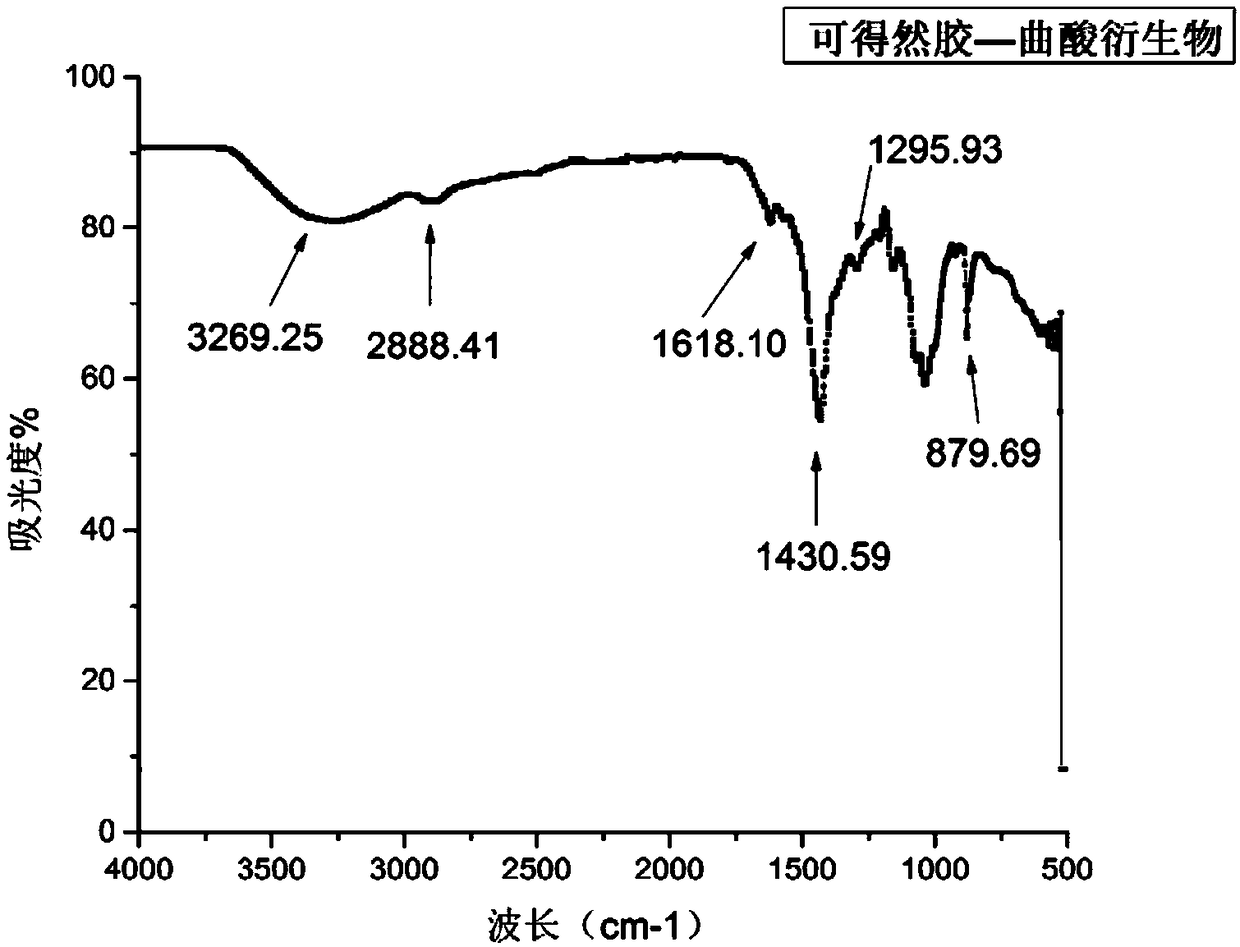

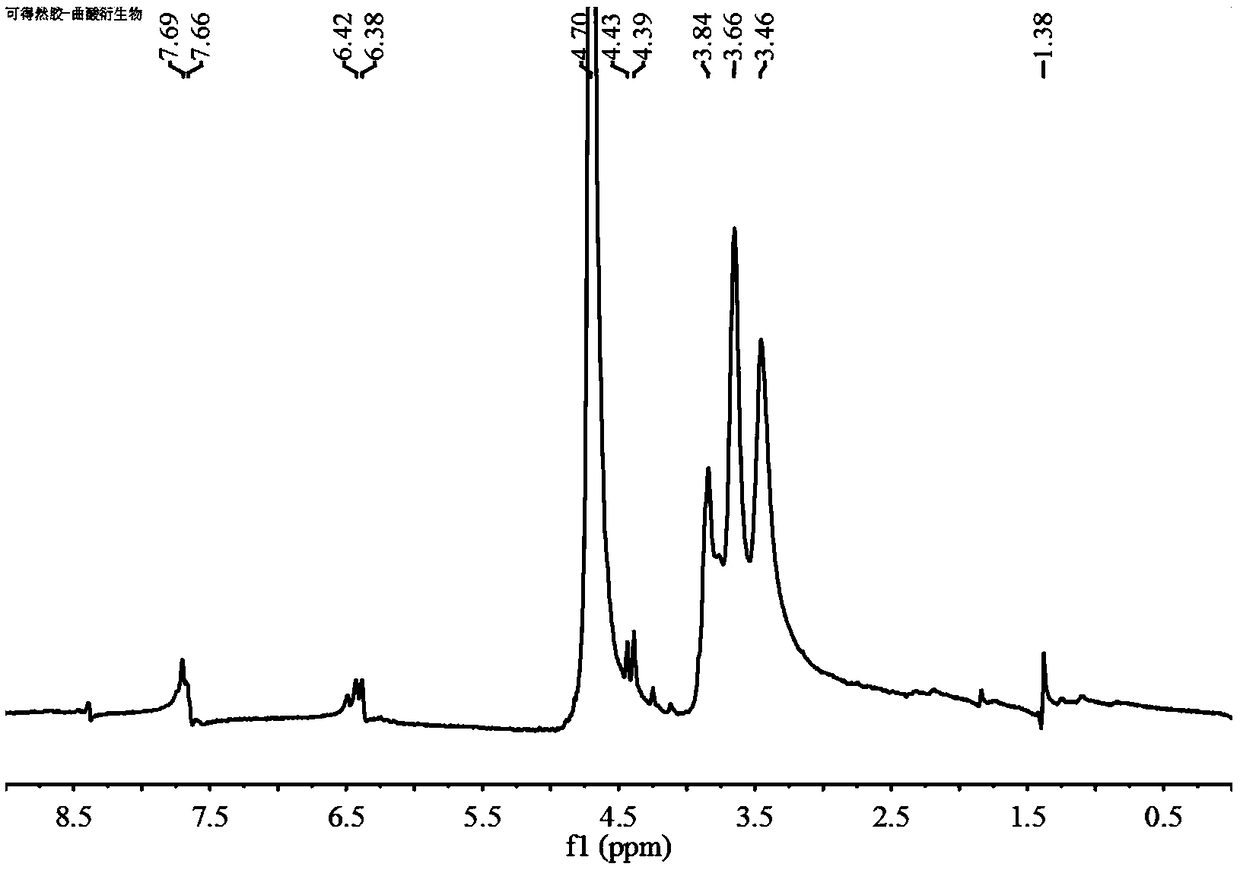

[0036] attached by figure 1 It can be seen that figure 1 Center at 3320.80cm -1 The broad peak at is the stretching vibration absorptio...

Embodiment 2

[0041] Preparation method: (1) Mix 5g of kojic acid and 25ml of dichloromethane solvent, add 10ml of thionyl chloride dropwise while stirring at room temperature, and react for 1h; (2) Dilute the product obtained in step (1) with petroleum ether After washing 2-3 times, filter to obtain kojic acid chlorinated, and dry it to obtain white or pink kojic acid chlorinated powder; (3) Take 0.5g of curdlan gum and disperse it in 30mL of water, then add 1g of kojic acid NaOH solid, stirred at room temperature for 1 hour to obtain curdlan gum-NaoH aqueous solution A; (4) Pour solution A into a three-necked flask and preheat to 30°C, add 3 g of kojic acid chlorinated solid under constant stirring, and react for 5 hours; (5) Precipitate a yellow solid curdlan-kojic acid derivative from the solution with absolute ethanol, and then dry the extracted yellow solid curdlan-kojic acid derivative. The degree of substitution of the obtained curdlan-kojic acid derivative was 101%.

Embodiment 3

[0043]Preparation method: (1) Mix 5g of kojic acid and 25ml of dichloromethane solvent, add 12ml of thionyl chloride dropwise while stirring at room temperature, and react for 1h; (2) Add petroleum ether to the product obtained in step (1) After washing 2-3 times, filter to obtain kojic acid chloride, and dry it to obtain white or pink kojic acid powder; (3) Take 0.5g of curdlan gum and disperse it in 30mL of water, then add 4g of kojic acid NaOH solid, stirred at room temperature for 24 hours to obtain curdlan gum-NaOH aqueous solution A; (4) Pour the A solution into a three-necked flask and preheat it to 70°C, add 5 g of kojic acid chlorinated solid under constant stirring, and react for 10 hours; (5) Precipitating the yellow solid curdlan-kojic acid derivative with a 2:1 mixture of absolute ethanol and acetone, and then drying the extracted yellow solid curdlan-kojic acid derivative, That's it. The degree of substitution of the obtained curdlan-kojic acid derivative was 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com