Graphene modified flame-retardant heat conducting nylon plastic and preparation method thereof

A graphene modification, nylon plastic technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of LED lamp life effect, material temperature increase, loss of nylon, etc., to improve heat dissipation effect and improve thermal conductivity. performance, improve the effect of energy exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

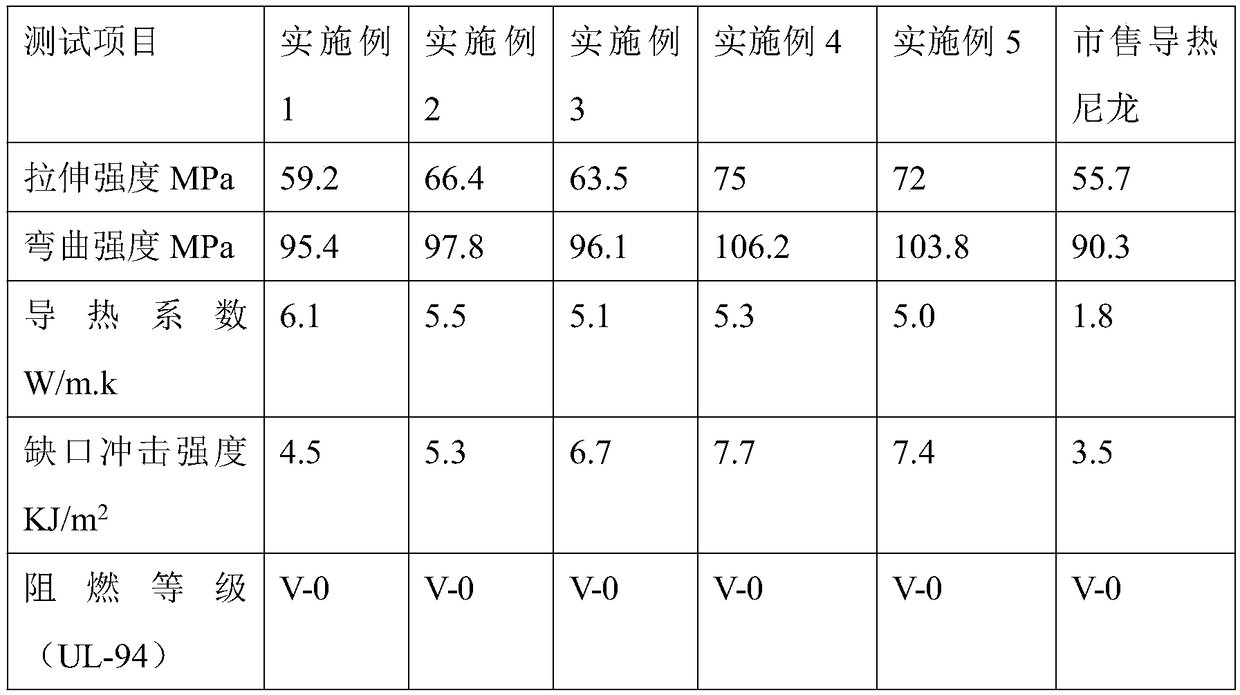

Examples

preparation example Construction

[0038] In the following examples, the preparation method of the graphene-modified flame-retardant heat-conducting nylon plastic comprises the following steps:

[0039] 1) Take various raw materials according to the above-mentioned formula;

[0040] 2) Dry the high-flow nylon 6 resin at a temperature of 70°C-80°C for 1-2 hours, and then mix it with all other raw materials;

[0041] 3) Put the mixed raw materials in the lower hopper of the extruder, and melt, extrude and granulate through the twin-screw extruder to obtain the graphene-modified flame-retardant and heat-conducting nylon plastic.

[0042] Further, the process parameters of the above-mentioned twin-screw extruder melt extrusion granulation are: the temperature of the first zone is 190-195°C, the temperature of the second zone is 225-230°C, the temperature of the third zone is 230-235°C, and the temperature of the fourth zone is 225-230°C , the temperature of the fifth zone is 220-225°C, the temperature of the sixth...

Embodiment 1

[0044] A graphene-modified flame-retardant and thermally conductive nylon plastic, comprising the following mass fractions:

[0045] High fluidity nylon 6 is 44%; negative ion powder 10%; sulfonated graphene 10%; spherical ceramic powder 3%; polyamide elastomer 6%; flame retardant 20%; flame retardant synergist 5%; processing Auxiliary 2%.

[0046] Among them, the negative ion powder is a compound of tourmaline powder and lanthanum chloride, and the compounding mass ratio is 1:2; the spherical ceramic powder is aluminum nitride; the flame retardant synergist is melamine cyanurate, and the processing aid is Antioxidant.

[0047] Prepare flame-retardant and heat-conducting nylon plastics according to the above-mentioned method.

Embodiment 2

[0049] A graphene-modified flame-retardant and thermally conductive nylon plastic, comprising the following mass fractions:

[0050] High fluidity nylon 6 is 54.5%; negative ion powder 8%; sulfonated graphene 7%; spherical ceramic powder 2%; polyamide elastomer 5%; flame retardant 18%; flame retardant synergist 4%; processing Auxiliary 1.5%.

[0051] Among them, the negative ion powder is a compound of tourmaline powder and lanthanum chloride, and the compounding mass ratio is 1:3; the spherical ceramic powder is silicon nitride; the flame retardant synergist is melamine orthophosphate, and the processing aid is anti Oxygen and lubricant.

[0052] Prepare flame-retardant and heat-conducting nylon plastics according to the above-mentioned method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com