Graphene powder metallic topcoat and preparation method thereof

A graphene powder and metal surface technology, applied in powder coatings, metal-free paints, anti-corrosion coatings, etc., can solve the problems of waste of resources, increase of project cost, limited weather resistance, etc., to improve decoration and aging resistance Performance, the effect of prolonging the aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

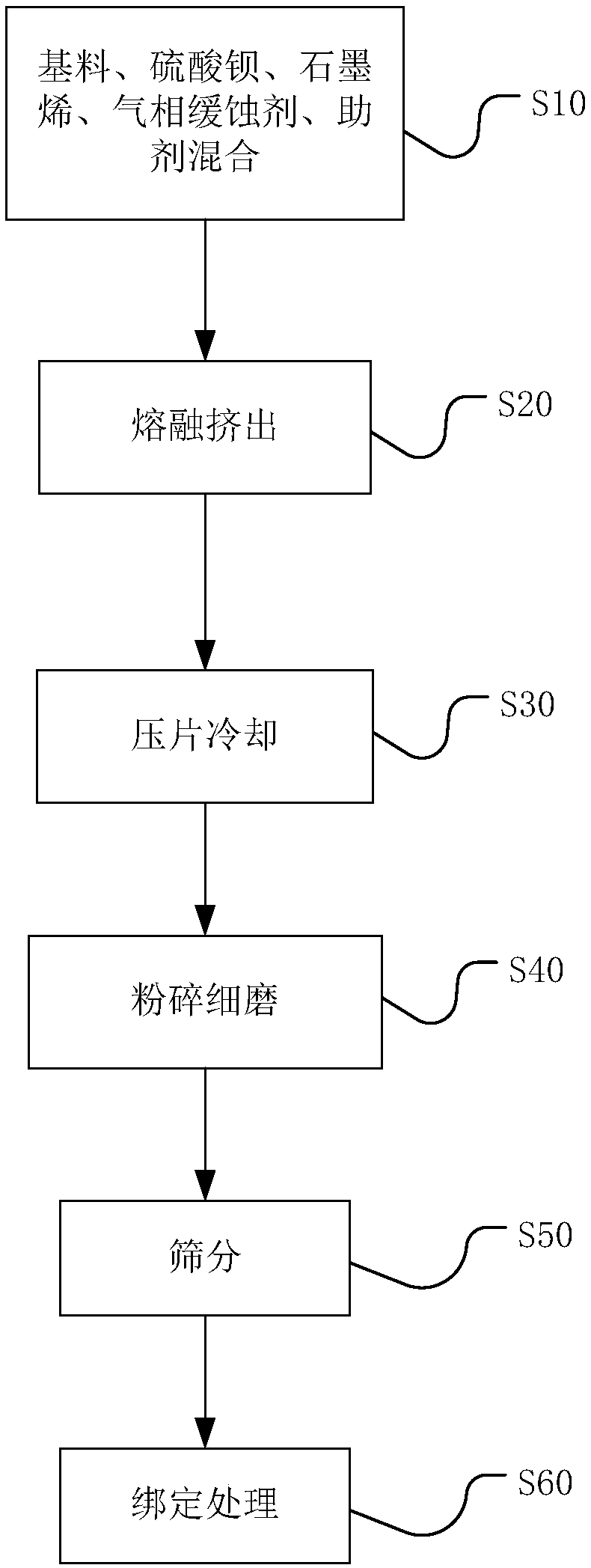

[0029] Hereinafter, the present invention will be described in more detail with reference to the accompanying drawings. Also, some well-known parts may not be shown. Numerous specific details of the present invention are described below, such as equipment, processes and techniques employed, in order to provide a clearer understanding of the present invention. However, the invention may be practiced without these specific details, as will be understood by those skilled in the art.

[0030] The invention can be embodied in various forms, some examples of which are described below.

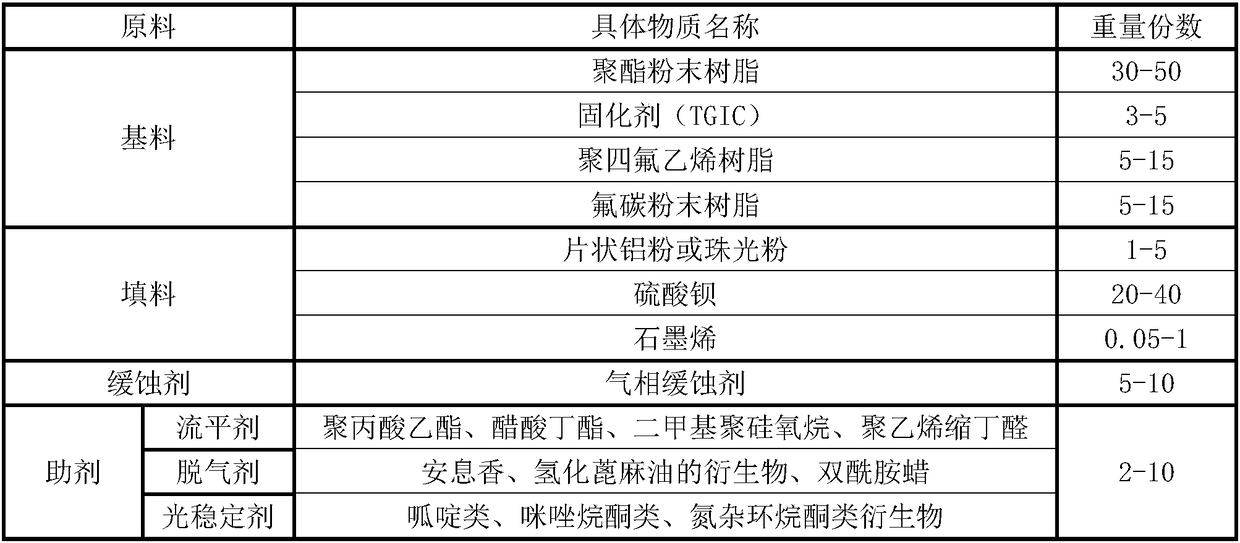

[0031] The raw materials of the embodiments of the present invention are shown in Table 1.

[0032]

[0033] The base material in the embodiment of the present invention is selected from resins with different weather resistance and mixed, such as polyester powder resin, polytetrafluoroethylene resin, fluorocarbon powder resin, the selection of the mixed resin, the proportion of each resin and T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com