Green ball distribution intelligent control system and control method

An intelligent control system and fabric distribution technology, which is applied in the field of metallurgy, can solve the problems of uneven distribution of vertical and horizontal material layers, and achieve the effects of improving production efficiency, avoiding uneven distribution, and increasing economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

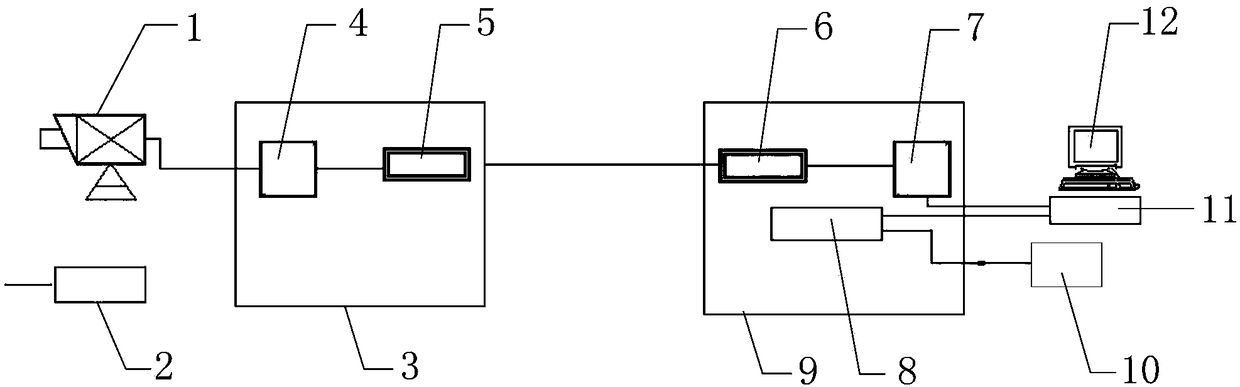

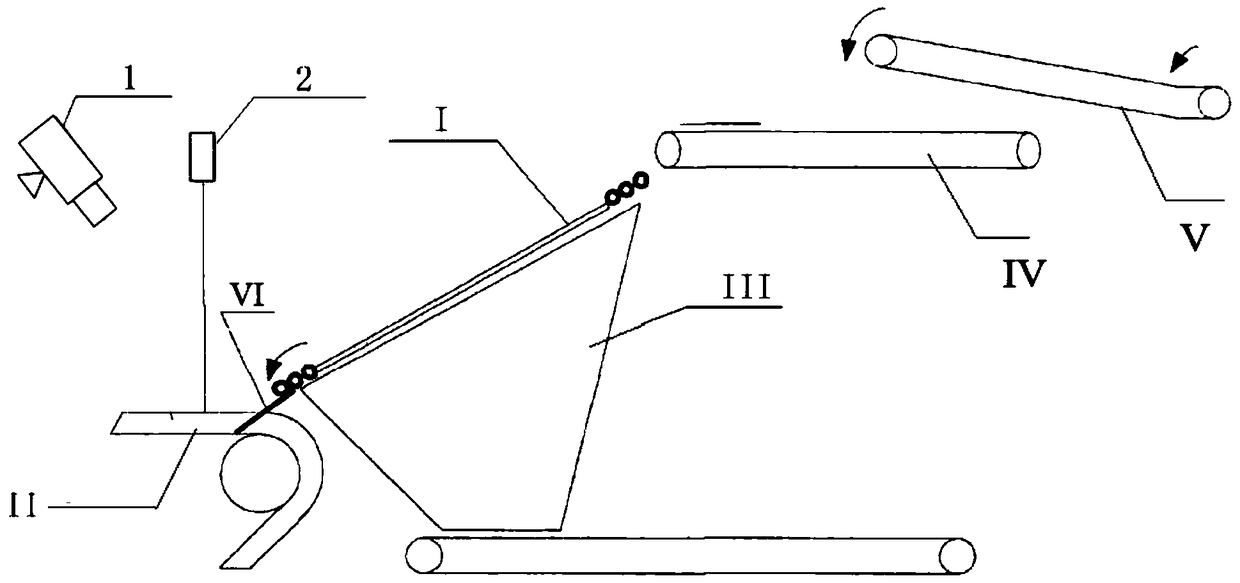

[0030] Such as figure 1 As shown, the raw ball cloth intelligent control system includes two industrial cameras 1, an inline laser transmitter 2, an on-site control box 3 with an electro-optical converter 4 and a first terminal splicing box 5, and a The electric cabinet 9 of the second terminal splicing box 6, photoelectric converter 7 and control parameter and alarm signal output device 8, the industrial computer 11 that is connected with photoelectric converter 7 and control parameter and alarm signal output device 8 respectively, and industrial control The display 12 connected to the machine 11; wherein, the signal transmission is realized by optical fiber between the electro-optical converter 4 and the photoelectric converter 7, and the two ends of the optical fiber are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com