A kind of preparation semiconductor material cu 2 o's method

A semiconductor and nano-semiconductor technology, applied in copper oxide/copper hydroxide and other directions, can solve the problems of high cost and unstable product quality, and achieve the effects of easy control, product stability, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Microwave synthesis of Cu 2 o

[0017] Weigh 1.2101g Cu(NO 3 ) 2 ·3H 2 O and 0.5924g PVP, measure 60mL of ethylene glycol, pour it into a 100mL beaker, stir it continuously with a glass rod until the solid is completely dissolved, at this time, the solution turns blue, then pour the blue solution in the beaker into a 250mL three-neck in the flask. Heat the mixed solution to 160 °C with a power of 600 W, the solution turns from blue to brick red precipitate, this process takes about 10 min, and then set the microwave holding time to 1 min, after the reaction is over, cool the mixed solution naturally to room temperature. Finally, the prepared mixed solution was centrifuged at 10,000 rpm for 5 min, and the brick-red precipitate was washed twice with absolute ethanol and distilled water, and washed with absolute ethanol for the last time. After washing, the samples were dried in an oven at 80 °C for several hours.

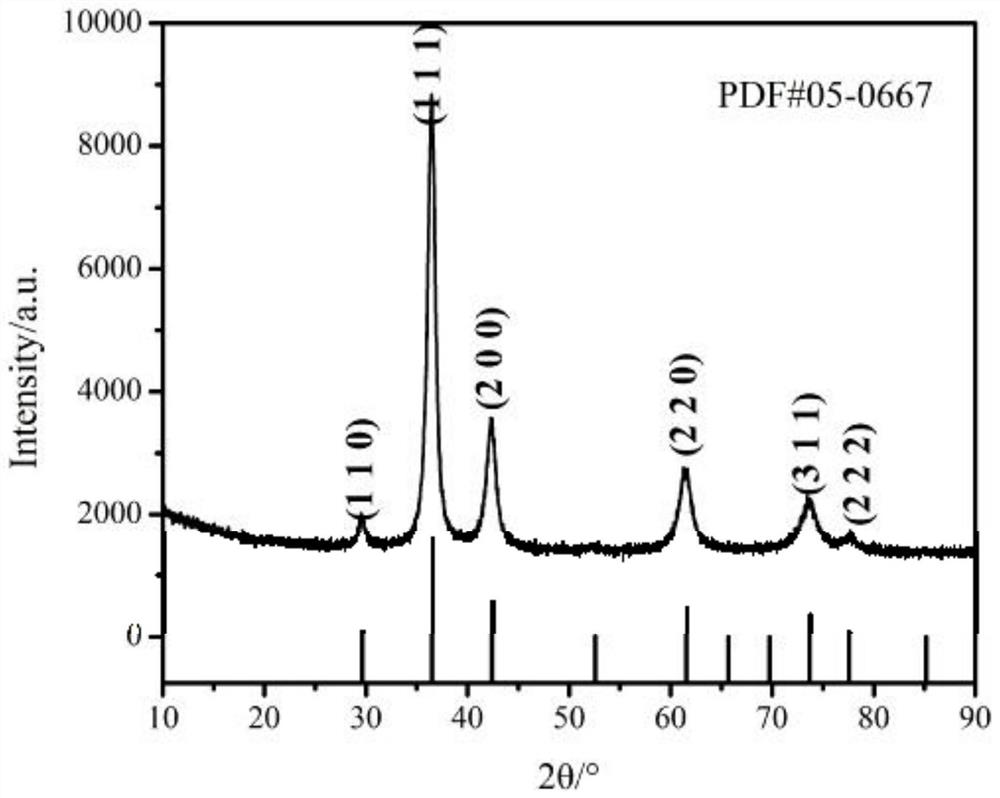

[0018] (2) Product composition and structural ...

Embodiment 2

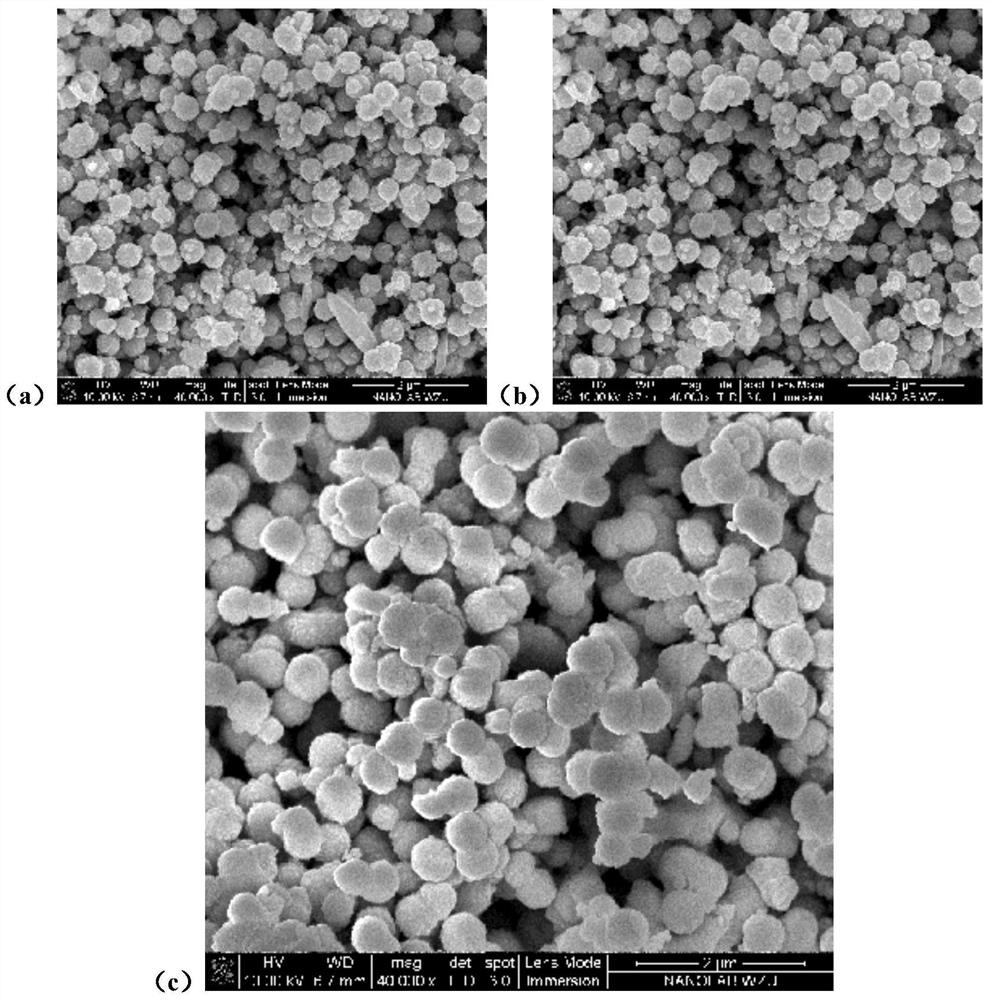

[0023] Reaction temperature on Cu 2 The effect of O morphology

[0024] figure 2 (a), (b) and (c) are prepared at reaction temperatures of 150°C, 160°C, and 170°C, respectively. 2 SEM image of O. Such as figure 2 (a), when the reaction temperature is 150°C, the morphology of the product is mostly spherical, and a small part is strip-shaped, and the spherical particle size distribution is relatively uniform. Such as figure 2 (b), when the temperature rises to 160 °C, the morphology of the product hardly changes, and the spherical particle size becomes larger. Such as figure 2 (c), when the reaction temperature rises to 170°C, the morphology of the product is spherical, the spherical particle size becomes larger and the distribution is more uniform, and the surface of the sphere becomes smooth.

Embodiment 3

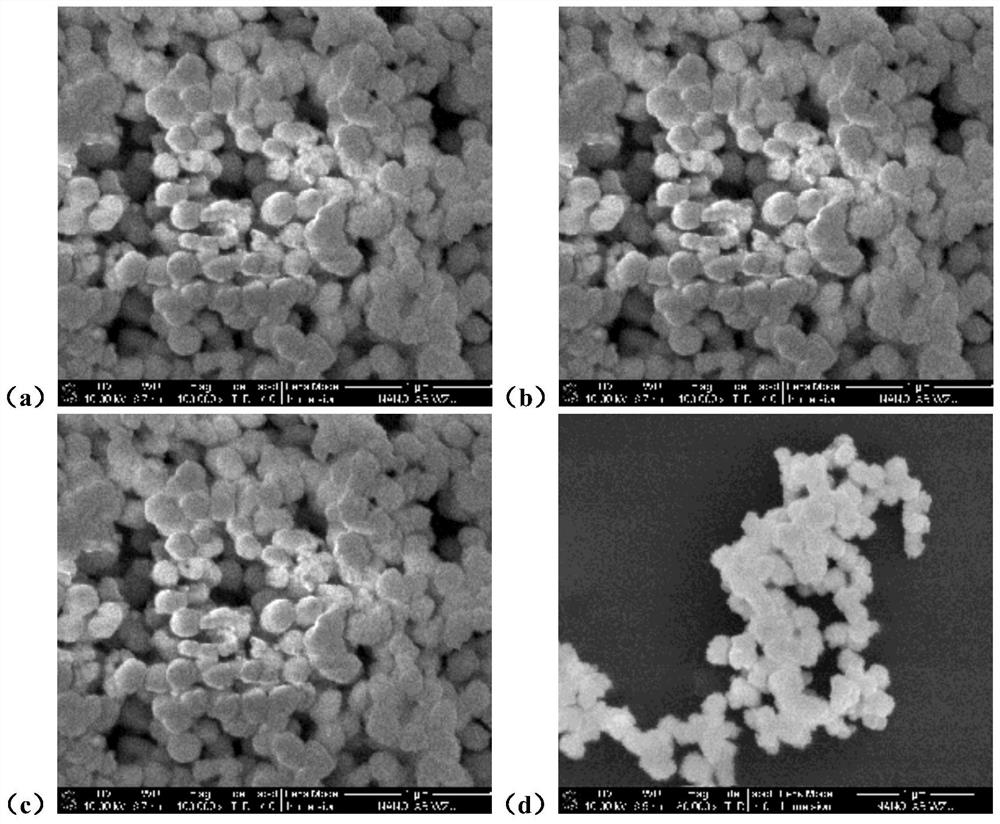

[0026] Holding time vs. Cu 2 The effect of O morphology

[0027] image 3 (a), (b), (c), and (d) are the Cu obtained under the holding time of 1min, 5min, 10min, and 20min, respectively. 2 SEM images of O samples. It can be seen from the figure that when the holding time is 1 min, the shape of the product is spherical with a smaller particle size, and when the holding time increases from 1 min to 20 min, the particle size of the product spherical particles also becomes larger. This is because when the holding time increases, the degree of reaction between particles is more sufficient, and the degree of particle aggregation increases, resulting in an increase in the particle size of aggregate particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com