Method for reducing cracking of dry-pressing molded strontium ferrite external-radial multi-polar magnetic ring

A strontium ferrite and multi-pole magnetic ring technology is applied in the field of reducing the cracking of dry-pressed strontium ferrite external radial multi-pole magnetic rings, and can solve the problem of increasing the unsafe factors in the production process, the magnetic leakage of the splicing gap, and increasing the production cost. and other problems, to achieve the effect of reducing the radial uneven shrinkage trend, no cracking problem, and improving product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Take 100 kg of Y35 strontium ferrite dry-pressed powder, add 1 kg of camphor powder and 1 kg of calcium stearate, stir and mix at 800 r / min for 180 min, then pass 60 Mesh sieve to get mixed powder;

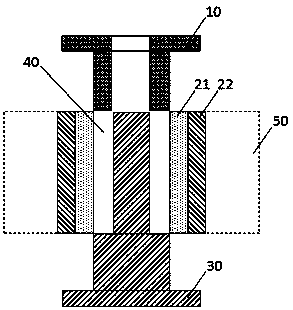

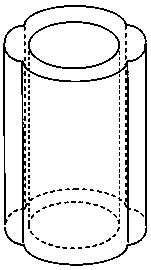

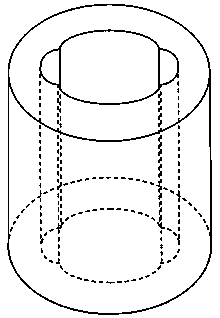

[0032] (2) Fill the mixed powder obtained in step (1) into the mold, and then press it into a ring green body. The structure of the mold is as follows: Figure 1-3 As shown; during molding, by applying a radial 4-pole magnetic field on the outer edge of the middle mold, the green body has an outer radial 4-pole orientation, the molding pressure is 25 MPa, the forming magnetic field strength is 5000 Oe, and the obtained green body has a density of 2.8 g / cm 3 ;

[0033] (3) Place the obtained body in an electric kiln, heat up to 1200°C at a rate of 3°C / min, sinter for 1.5 h, and grind;

[0034] (4) Magnetize and inspect the ground product.

[0035]The results show that the average value of the peak value of the surface magnetic flux density of the obtained ferrite out...

Embodiment 2

[0037] (1) Take 100 kg of Y45 strontium ferrite dry-pressed powder, add 1 kg of camphor powder, add 0.5 kg of stearic acid amide (-325 mesh) and 0.5 kg of oleic acid amide (-325 mesh), and stir Mixing, the rotating speed is 29000 r / min, the time is 5min, then passes through a 40 mesh sieve to obtain the mixed powder;

[0038] (2) Fill the mixed powder obtained in step (1) into the mold, and then press and form it into a ring green body. The mold structure is as follows: Figure 1-3 As shown; during molding, by applying a radial 4-pole magnetic field on the outer edge of the middle mold, the green body has an outer radial 4-pole orientation, the molding pressure is 12 MPa, the forming magnetic field strength is 8000 Oe, and the obtained green body has a density of 2.85 g / cm 3 ;

[0039] (3) Place the obtained body in an electric kiln, heat up to 1145°C at a rate of 3°C / min, sinter for 2.5 hours, and grind;

[0040] (4) Magnetize and inspect the ground product.

[0041] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com