A method for auxiliary brazing of low-expansion flexible intermediate layer

An intermediate layer and low expansion technology, which is applied in the field of intermediate layer auxiliary brazing, can solve the problems of large differences in residual stress of brazed joints, increased weld brittleness, and small introduction of ceramic reinforcement phase, so as to maintain its own characteristics and eliminate porosity, to ensure the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

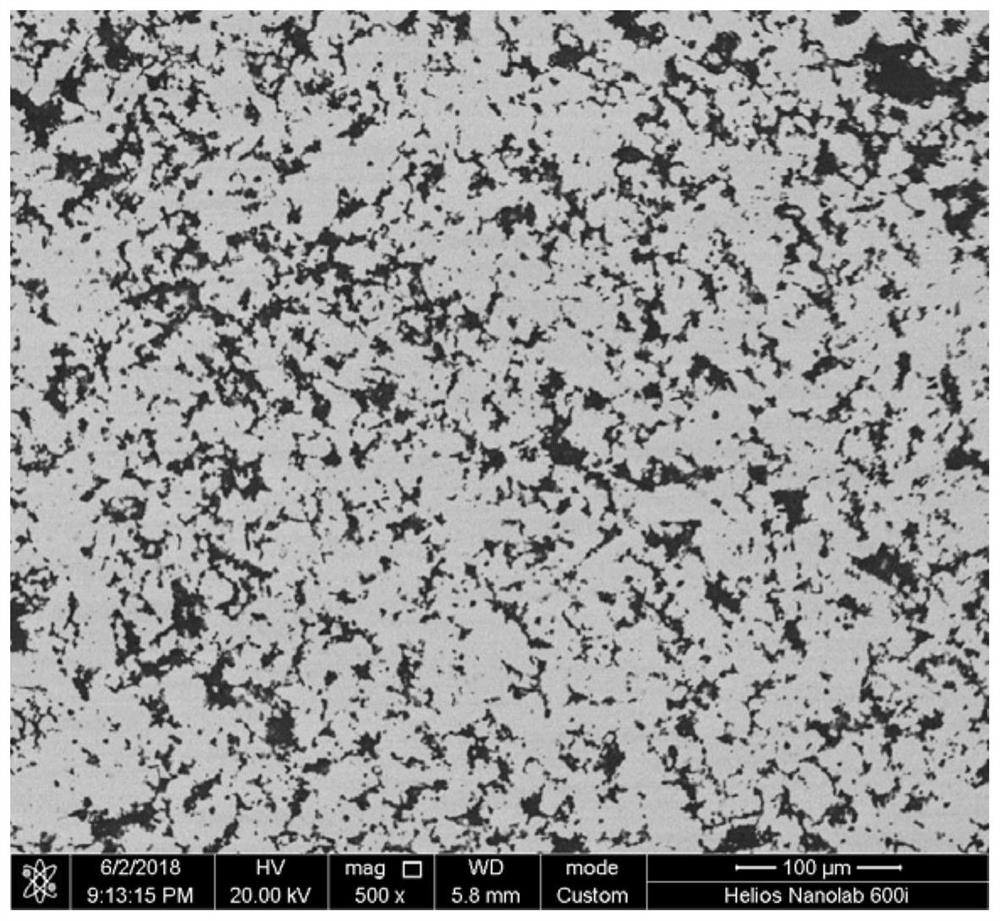

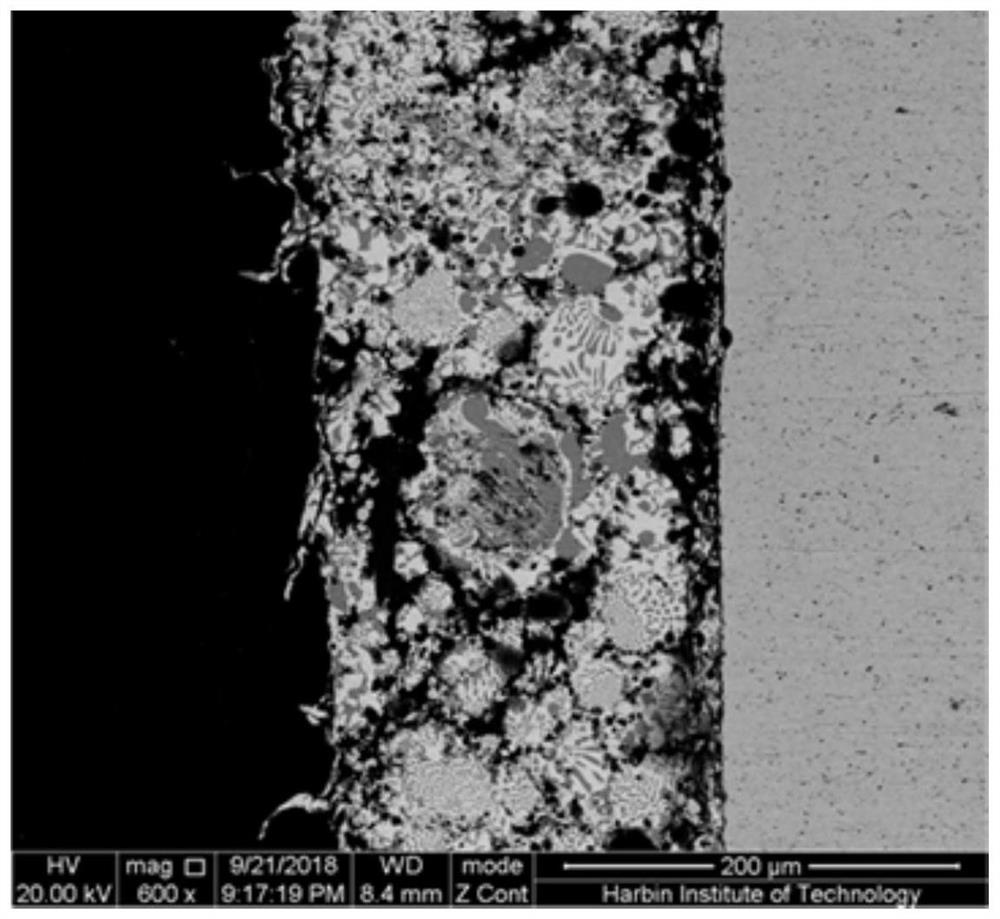

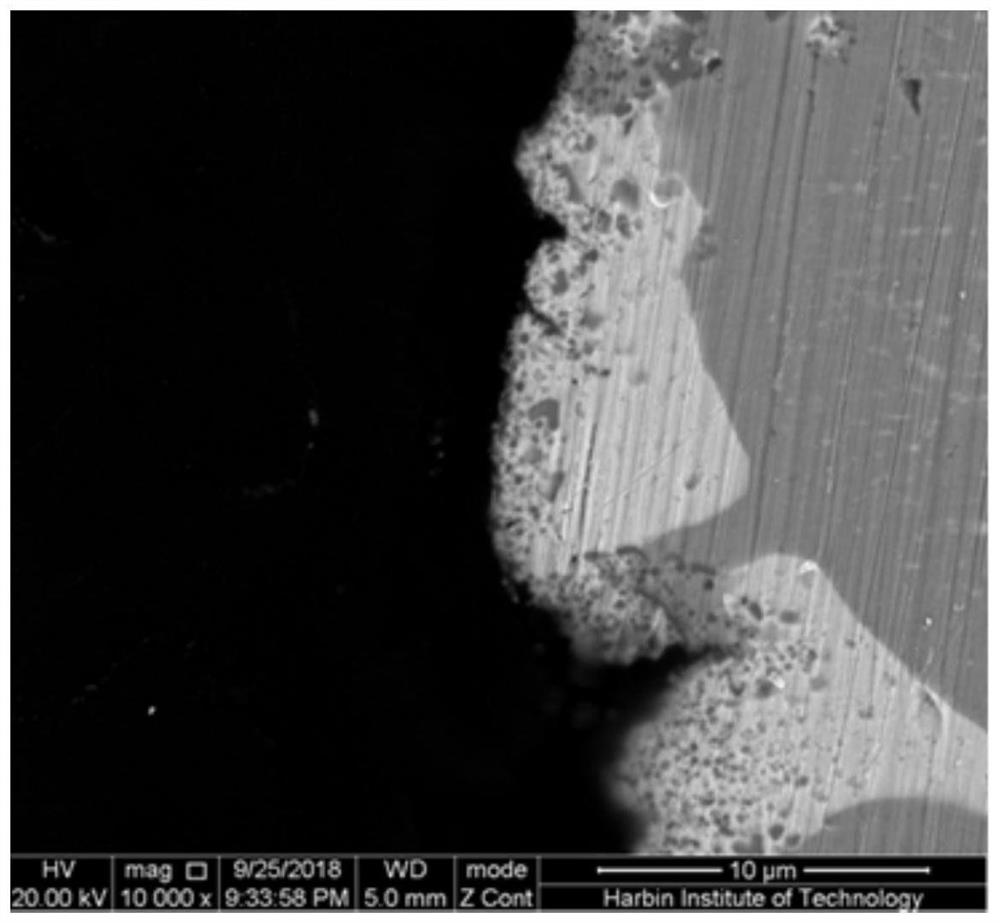

Image

Examples

specific Embodiment approach 1

[0022] Specific Embodiment 1: In this embodiment, a method for auxiliary brazing of a low-expansion flexible intermediate layer is carried out according to the following steps:

[0023] 1. Weigh 40% to 80% negative thermal expansion coefficient powder, 1% to 10% coupling agent powder and the rest of the metal matrix powder by volume percentage, and first ball mill the weighed negative thermal expansion coefficient powder and coupling agent powder Mix, and then vacuum anneal at a temperature of 800°C to 1200°C for 10min to 20min to obtain annealed mixed powder, mix the annealed mixed powder with the weighed metal matrix powder, and then place it in a graphite mold for heating Press sintering, the sintering temperature is 700°C-1100°C, the sintering time is 0.5h-5h, and finally the sintered block is cut to obtain a low-expansion flexible middle layer;

[0024] The negative thermal expansion coefficient powder is Zr 2 P 2 WO 12 powder or LiAlSiO 4 powder;

[0025] 2. Mechani...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 2 in that the purity of the metal matrix powder described in step 1 is 99.9%. Others are the same as in the second embodiment.

specific Embodiment approach 3

[0031]Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the metal matrix powder described in step 1 is Cu powder or Ni powder. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com