Vegetable oil polyurethane soft foam polyol, and preparation method and application thereof

A technology for vegetable oil polyol and polyurethane soft foam, which is applied in the preparation of polyurethane materials, vegetable oil polyurethane soft foam polyol and the field of preparation thereof, can solve the problem that the preparation process is cumbersome, does not conform to the sustainable development strategy of green chemical industry, and is not suitable for the production of polyurethane soft foam. materials and other issues, to achieve the effect of rich sources, green raw materials, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

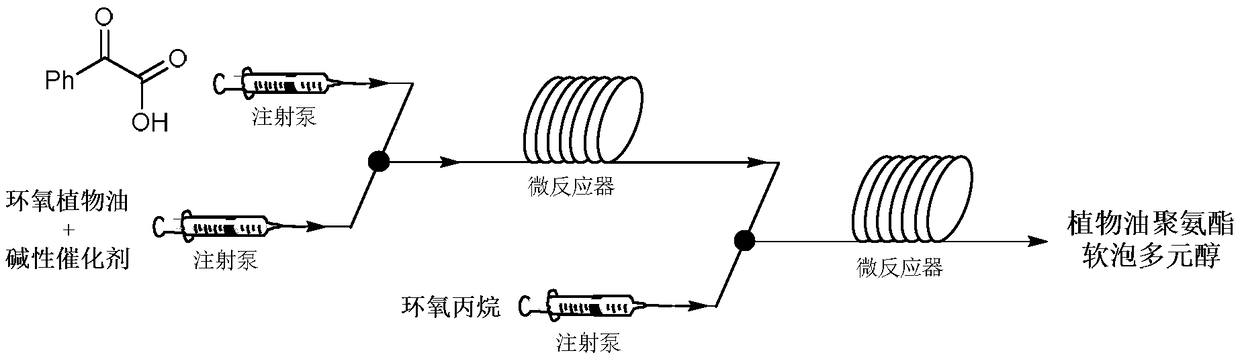

Method used

Image

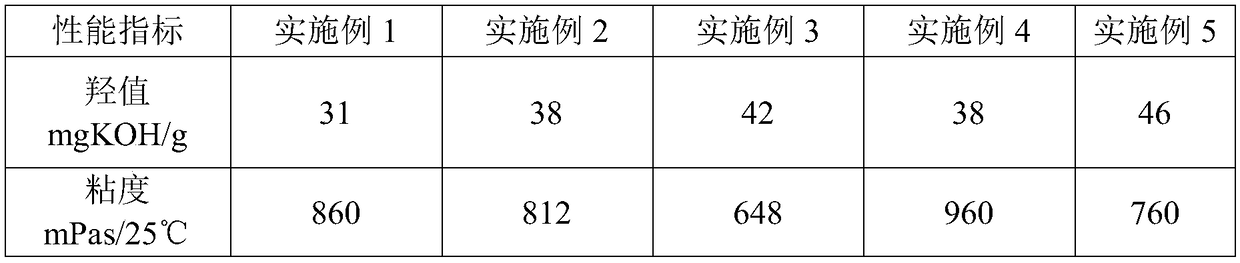

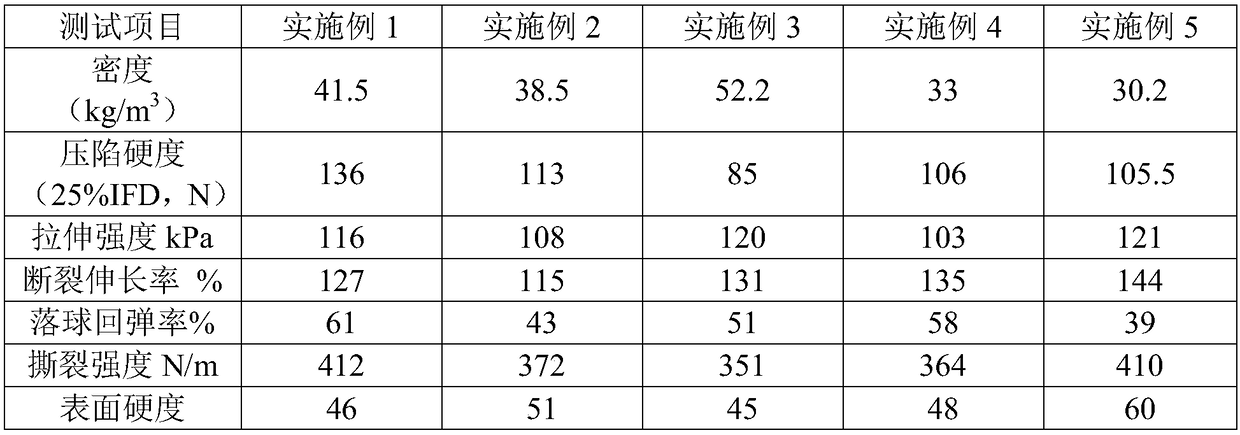

Examples

Embodiment 1

[0046] Take 50.57g benzoylformic acid and dissolve it in 600mL dichloromethane to obtain mixed solution A; get 100g epoxidized soybean oil and 0.08g sodium carbonate and dissolve it in 600mL dichloroethane to obtain solution B; get 91.58g propylene oxide and dissolve it in 1200mL dichloromethane Obtaining solution C of ethyl chloride; Wherein the mol ratio of epoxy group and benzoylformic acid in epoxy soybean oil is 1: 1.2, the mass percent of sodium carbonate and epoxy soybean oil is 0.08%, in epoxy soybean oil The molar ratio of epoxy group to propylene oxide is 1:15; the mixed solution A and solution B are simultaneously pumped into the first micro-mixer in the micro-channel reaction device, and after being fully mixed, they are passed into the first micro-channel reactor for Ring-opening reaction to obtain a reaction solution containing vegetable oil polyols; pump the obtained reaction solution containing vegetable oil polyols and solution C into the second micro-mixer in ...

Embodiment 2

[0048] Take 75.82g of benzoylformic acid and dissolve it in 600mL of dichloromethane to obtain a mixed solution A; take 100g of epoxidized soybean oil and 0.02g of sodium carbonate and dissolve it in 600mL of dichloroethane to obtain a solution B; take 61.05g of propylene oxide and dissolve it in 1200mL of dichloromethane Obtaining solution C of ethyl chloride; Wherein the mol ratio of epoxy group and benzoylformic acid in epoxy soybean oil is 1: 0.8, the mass percent of sodium carbonate and epoxy soybean oil is 0.02%, in epoxy soybean oil The molar ratio of epoxy group to propylene oxide is 1:10; the mixed solution A and solution B are simultaneously pumped into the first micro-mixer in the micro-channel reaction device, and after being fully mixed, they are passed into the first micro-channel reactor for Ring-opening reaction to obtain a reaction solution containing vegetable oil polyols; pump the obtained reaction solution containing vegetable oil polyols and solution C into...

Embodiment 3

[0050] Get 94.81g of benzoylformic acid and dissolve it in 600mL of dichloromethane to obtain mixed solution A; get 100g of epoxidized soybean oil and 0.1g of sodium carbonate and dissolve it in 600mL of dichloroethane to obtain solution B; get 122.11g of propylene oxide and dissolve it in 1200mL of dichloromethane Obtaining solution C of ethyl chloride; Wherein the mol ratio of epoxy group and benzoylformic acid in epoxy soybean oil is 1: 1.5, the mass percent of sodium carbonate and epoxy soybean oil is 0.1%, in epoxy soybean oil The molar ratio of epoxy group to propylene oxide is 1:20; the mixed solution A and solution B are simultaneously pumped into the first micro-mixer in the micro-channel reaction device, and after being fully mixed, they are passed into the first micro-channel reactor for Ring-opening reaction to obtain a reaction solution containing vegetable oil polyols; pump the obtained reaction solution containing vegetable oil polyols and solution C into the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com