Process method for highly-wear-resistant silicone product

A process method and high wear-resistant technology, applied in the field of high wear-resistant silicone products, can solve the problems of high energy consumption, easy peeling off of the button coating, low efficiency, etc., and achieve the effect of improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

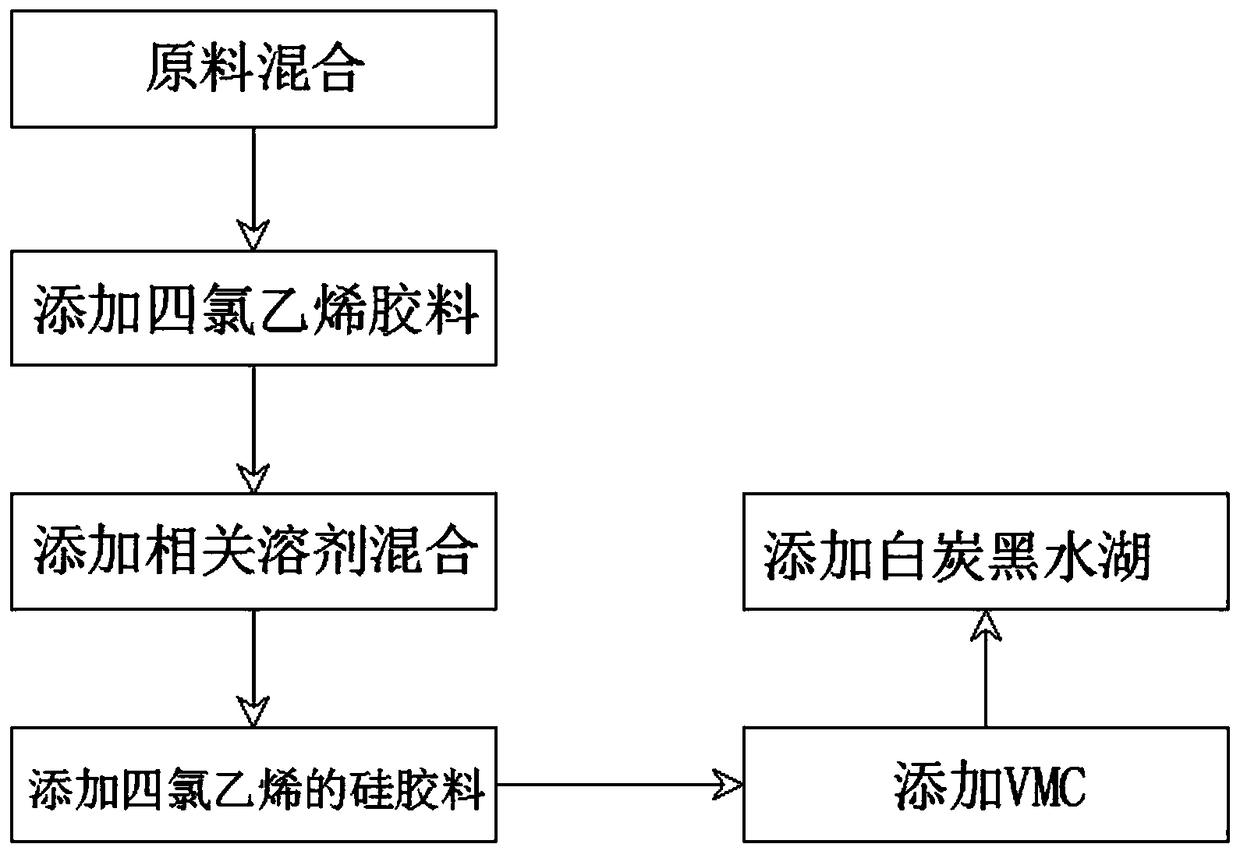

[0020] The embodiment provided by the present invention: a process method of high wear-resistant silica gel products, the polyorganosiloxane raw rubber with a degree of polymerization of 1000 or more is 120 parts, reinforcing white carbon black is 12-120 parts, and the specific surface area is 1 8-220 parts of inorganic filler of 50 m2 / g, 120 parts of chlorine resin powder with a particle size of 0.05-120 mm, and 0.1-12 parts by weight of organic peroxide, it is characterized in that: the preparation method comprises the following steps: step 1: Prepare the above-mentioned sufficient amount of raw materials and mix them to make silica gel raw materials; Step 2: In order to improve the tensile strength and tear strength of silica gel products, add polytetrachlorethylene rubber to the silica gel raw materials; Step 3: Add polytetrafluoroethylene to the silica gel raw materials Add silicone resin, silicone oil, and polytetrachloroethylene in turn to mix, and then add silicone rubb...

Embodiment 2

[0032]A process method for high wear-resistant silicone products. The effect of adding the amount of VMC on the wear resistance of the coating. By changing the amount of VMC, the silicone rubber raw rubber with different ethylene content in the molecular structure can be obtained through chemical reaction. During the reaction, adjust different doses of VMC and add excess hydrogen-containing silicone oil and PT catalyst to spray and fix the phone. After the reaction, the finished product will be tested for friction resistance on the test bench. Through many experiments, it is known that As the ethylene content in the molecular structure increases, the number of frictions that the silicone rubber coating can withstand will also increase, and the number of frictions it will withstand will decrease after reaching a certain level, making the cured coating less Brittle and easy to break.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com