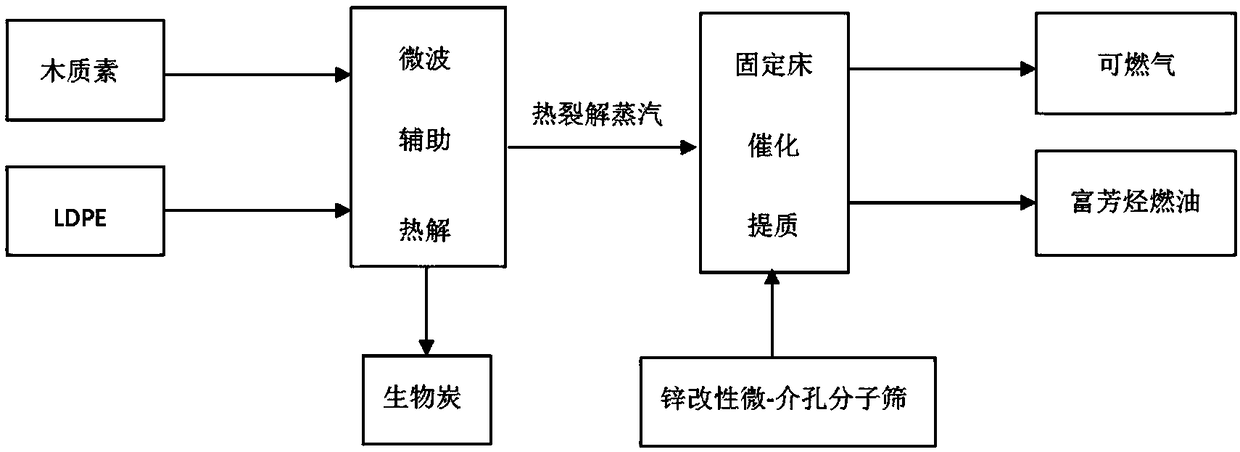

Method for preparing arene-rich fuel oil by co-pyrolysis of lignin and low-density polyethylene

A low-density polyethylene and lignin technology, which is applied in the treatment of hydrocarbon oil, hydrocarbon oil treatment products, chemical instruments and methods, etc., can solve the problems of rarely being effectively used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

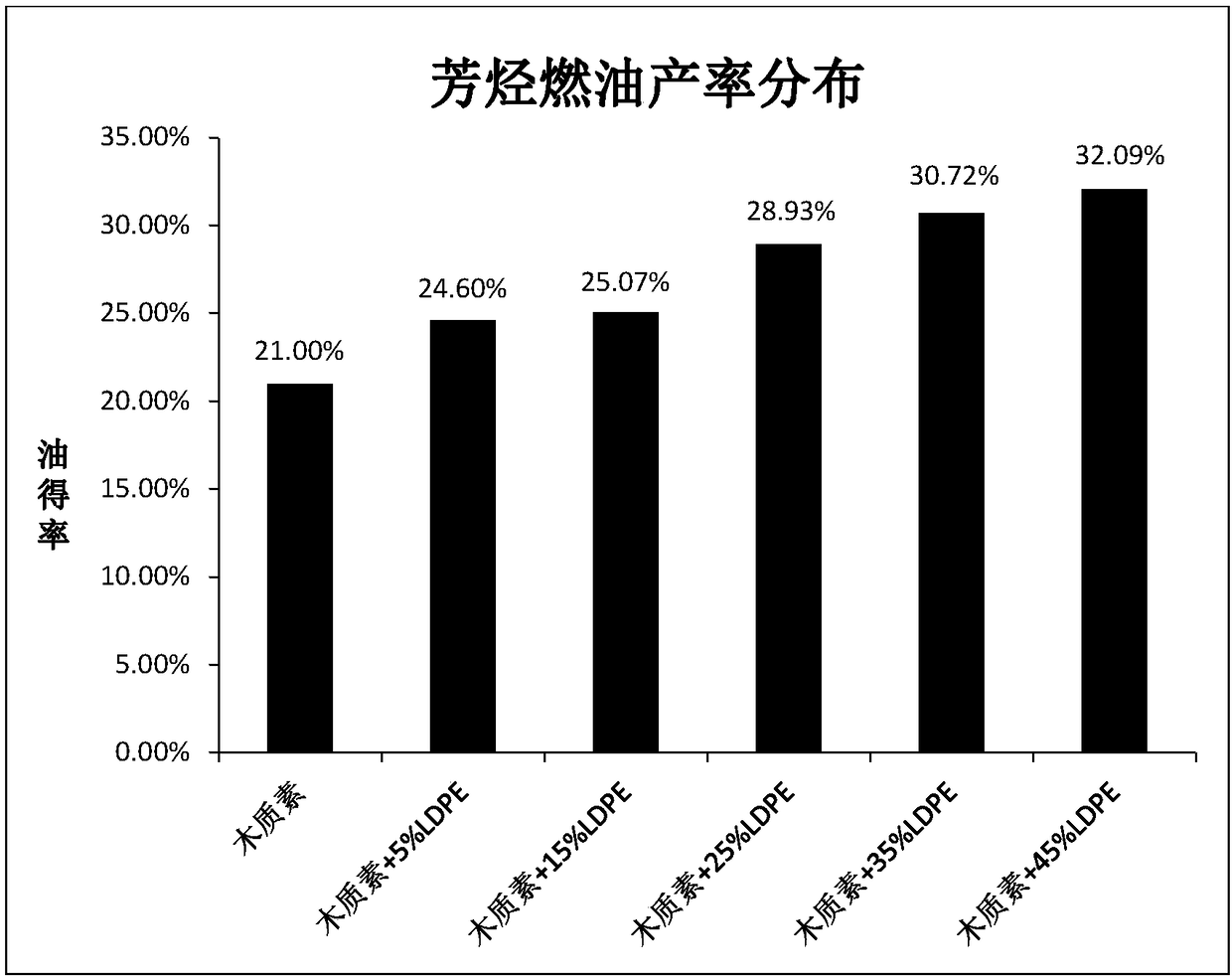

[0032] Embodiment one: determine optimum LDPE addition ratio.

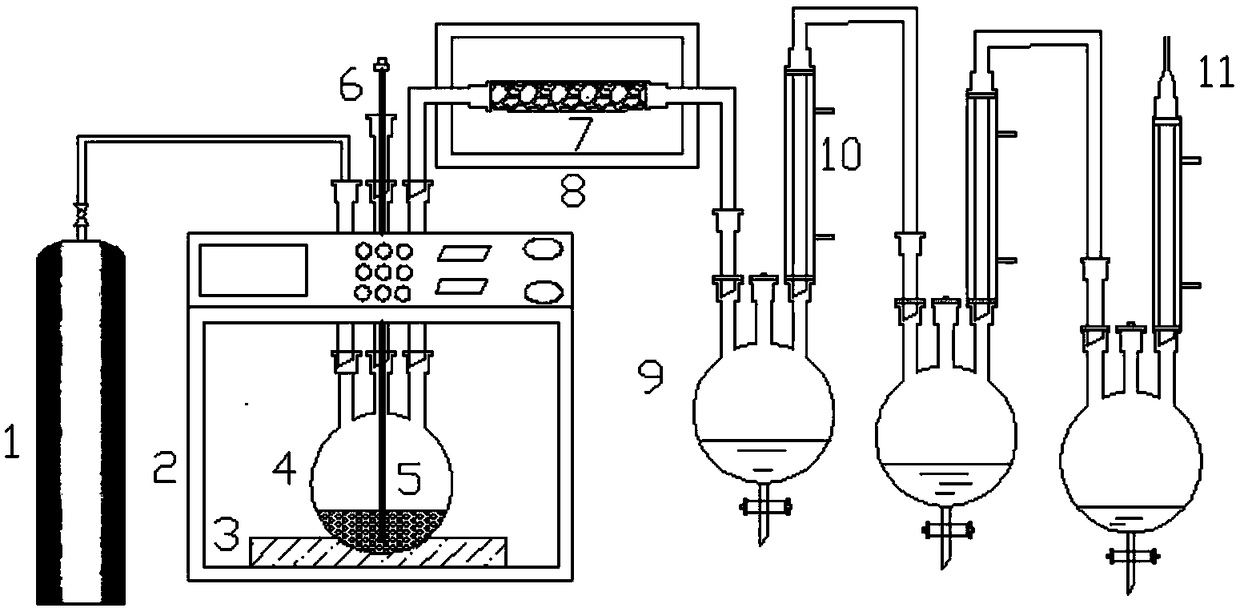

[0033] The raw materials used in the test are lignin and LDPE, first take by weighing 30g lignin and LDPE as reaction raw material 5 (a total of five groups of experiments, LDPE additions are respectively 5%, 15%, 25%, 35% of the lignin quality, 45%) in the 500mL three-necked flask 4, and then the three-necked flask 4 is placed in the microwave reactor 2, the left port of the three-necked flask 4 is connected to the nitrogen cylinder 1, the middle port is inserted into the temperature measuring tube 6, and the right port is inserted into the catalytic fixed bed reaction The quartz tube that device 8 is connected, in catalytic fixed-bed reactor 8 (fixed-bed reactor 8 reaction temperature of five groups of experiments is all 450 ℃), the Zn modification of 1.5g (addition amount is 5% of lignin quality) ZSM-5 / MCM41 catalyst, the device is sealed and connected, and nitrogen is introduced to exhaust the air. Set the re...

Embodiment 2

[0035] Embodiment 2: Determining the optimum temperature for catalytic fixed-bed reaction.

[0036]The used raw material of test is lignin and LDPE, at first take by weighing the lignin raw material of 30g and the LDPE of 7.5g (determining that the optimum LDPE addition is 25% of lignin quality by the result of embodiment one) is put in the 500mL quartz flask, Place the quartz flask in the microwave oven again, and place 1.5g (addition amount is lignin quality) 5%) Zn modified ZSM-5 / MCM41 catalyst. Set the reaction temperature of microwave pyrolysis to 450°C, the reaction time to 15min, and the microwave power to 750W; the co-pyrolysis steam generated by the microwave pyrolysis reaction passes through the catalytic fixed bed for catalytic reforming reaction, and then the fuel is collected after rapid condensation Oil, the fuel oil after the reaction was collected and analyzed by GC / MS. In the experiment, four groups of microwave pyrolysis experiments with different catalytic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com