Application method of biological bacterial agent for straw biogas fermentation pretreatment

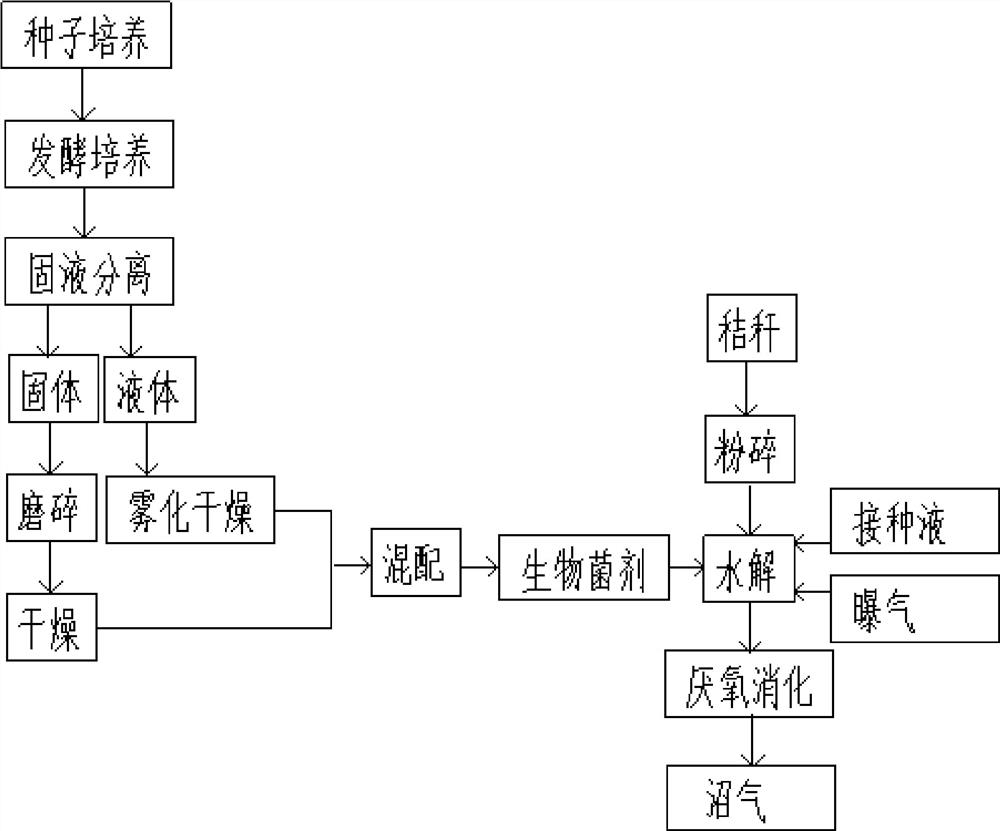

A biological bacterial agent and biogas fermentation technology, applied in the field of bioengineering, can solve the problems of inefficient biological bacterial agent and long treatment period, and achieve the effects of simple and easy-to-control application method, fewer fermentation steps, and improved hydrolysis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for producing a biological bacterial agent for straw biogas fermentation pretreatment, comprising the following steps:

[0032] S1. Cultivation of seed liquid: inoculate Aspergillus niger (Aspergillus niger) suspension into 200ml seed culture medium, the inoculum size is 10mL, and cultivate in constant temperature phase for 1 day at 28°C to obtain seed liquid, seed liquid The OD600nm of the culture solution is 0.687;

[0033] The seed medium is specifically KH 2 PO 4 1.0 g / L, MgSO 4· 7H 2 O0.3 g / L, NH 4 Cl 2.0 g / L, sodium carboxymethylcellulose (CMC-Na) 5.0 g / L, NaOH adjusts the pH value to 7.0;

[0034] S2. Fermentation culture: Take 50 mL of the seed liquid obtained in S1 and inoculate it into a fermenter with an effective volume of 1 L. Before use, the fermenter is sterilized by high-temperature steam for 2 hours, cultivated in a constant temperature water bath at 28°C for 24 hours, and injects sterile air to control Dissolved oxygen (DO) is 0.1, and t...

Embodiment 2

[0047] A method for producing a biological bacterial agent for straw biogas fermentation pretreatment, comprising the following steps:

[0048] S1. Cultivation of seed liquid: inoculate the Aspergillus niger suspension into 200ml seed culture medium, the inoculum size is 40mL, cultivate in constant temperature phase for 3 days, and the cultivation temperature is 35°C to obtain seed liquid, the culture liquid OD600nm of the seed liquid is 1.115;

[0049] The seed medium is specifically KH 2 PO 4 1.0 g / L, MgSO 4· 7H 2 O0.3 g / L, NH 4 Cl 2.0 g / L, sodium carboxymethylcellulose (CMC-Na) 5.0 g / L, NaOH adjusts the pH value to 7.0;

[0050] S2. Fermentation culture: Take 200 mL of the seed liquid obtained in S1 and inoculate it into a fermenter with an effective volume of 1 L. Before use, the fermenter is sterilized by high-temperature steam for 2 hours, cultivated in a constant temperature water bath at 35°C for 30 hours, and injects sterile air to control Dissolved oxygen (DO) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com