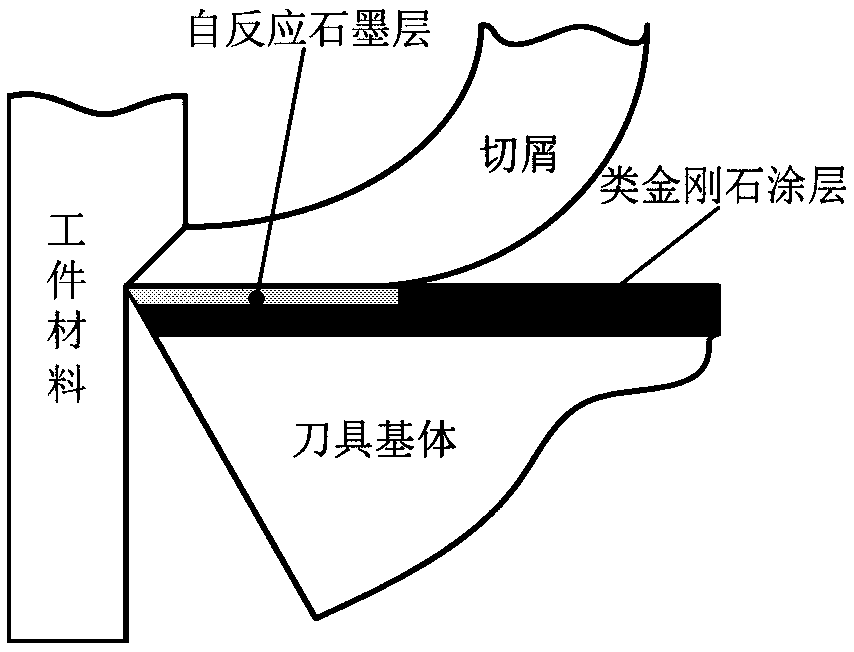

Diamond-like in-situ self-reaction graphitized lubricating coating cutter and preparation method thereof

A technology of diamond coating and lubricating coating, which is applied in the direction of metal material coating process, coating, ion implantation plating, etc., and can solve problems such as the gap in lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] A diamond-like in-situ self-reaction graphitization lubricating coating turning insert, the base material of the insert is YG-like cemented carbide, the total thickness of the diamond-like coating on the surface of the insert is 10 μm, and the thickness of the inner layer of the diamond-like coating is 6 μm. The thickness of the outer layer of the coating is 4 μm, and the outer layer contains 3 atomic percent of transition metal element cobalt.

[0013] The preparation method of the diamond-like in-situ self-reaction graphitization lubricating coating turning insert is as follows:

[0014] (1) Pre-treatment: Grind the YG-type cemented carbide blade, put it into absolute ethanol for ultrasonic cleaning for 15 minutes, and dry it in vacuum.

[0015] (2) Select high-purity graphite as the sputtering target, methane as the reaction gas, and pass a mixed gas of hydrogen and argon, and adopt the method of reactive magnetron sputtering to deposit the inner layer of the diamond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com