Hot air mixed type flue gas white smoke elimination system and elimination method thereof

A hybrid and flue gas technology, applied in the field of air pollutant control, can solve the problems of increasing the operating cost of power plants, affecting industrial production, corroding chimneys, etc., and achieving the effects of cost saving, reasonable structure design and reducing equipment resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention are described in detail below through the examples, and the following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations to the technical solutions of the present invention.

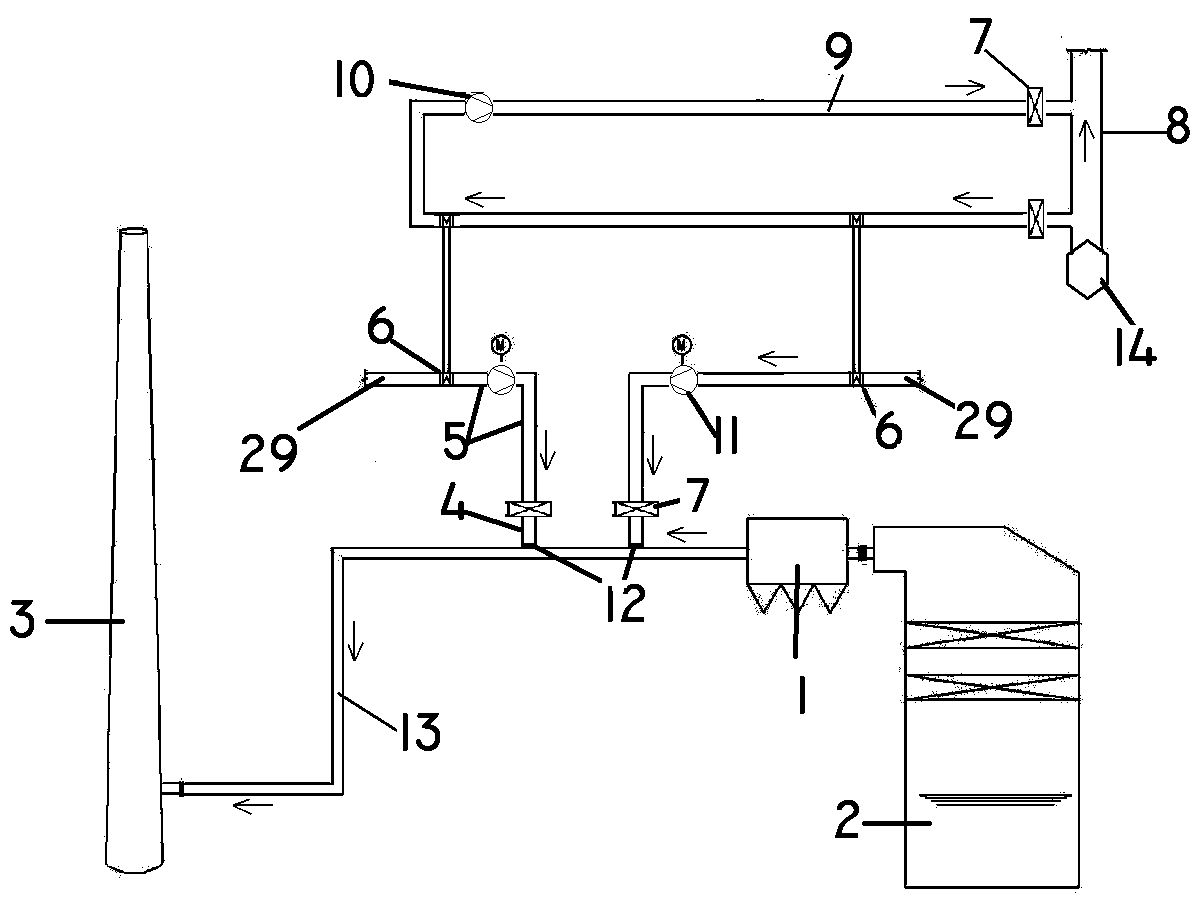

[0046] Such as figure 1As shown, the present invention provides a hot air mixed flue gas white smoke elimination system, including a heating unit, a dust remover 1, an absorption tower 2 and a chimney 3, the flue gas outlet on the upper part of the absorption tower 2 communicates with the inlet of the dust collector 1 through a pipeline, and the dust removal The outlet of the device 1 communicates with the lower part of the chimney 3 through the smoke cleaning pipe 13; the smoke cleaning pipe 13 is provided with at least two hot air branch pipes 4 at intervals. A baffle door 12 is arranged between the hot air branch pipe 4 and the smoke ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com