Degradable metal stent and preparation method thereof

A technology of metal stents and metal zinc, which is applied in the field of medical devices, can solve problems such as the toxicity of stent implantation sites, and achieve the effects of improving biological safety, simple preparation methods, and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0091] A preparation method of a degradable metal stent provided by the invention comprises the following steps:

[0092] S1: Cut the metal stent into a structure with accommodating space. After the cutting is completed, a drug coating can also be sprayed on the outer wall and / or inner wall of the stent. The drug coating includes a drug and a drug carrier. Pamycin, the drug carrier can be polylactic acid.

[0093] S2: preparing a chelating agent coating solution containing a chelating agent and a carrier.

[0094] S3: Add the chelating agent coating solution dropwise into the accommodating space, and wait for the solvent to volatilize.

[0095] S4: Repeat step S3 until the accommodating space is filled.

[0096] In another embodiment of the present invention, a method for preparing a degradable metal stent including a protective layer is also provided, and S1-S3 of the preparation method are the same as above, except that S4: repeat step S3 several times ; S5: Configure a coa...

Embodiment 1

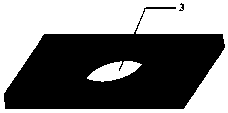

[0103] Please refer to Figure 7 , is a partially enlarged view of a degradable metal stent provided by the present invention. The preparation method is as follows:

[0104] S1: Cut the degradable metal stent into a structure with through holes in the stent rod.

[0105] S2: Calcium sodium edetate (CaNa 2 EDTA) as chelating agent, PLA as carrier, solvent adopts n-propyl acetate. Prepare a solution of PLA and n-propyl acetate with a concentration of 2% (w / v); calcium sodium edetate (CaNa 2 EDTA) is dissolved in water at first into the higher mother liquor of concentration, then mother liquor is added dropwise in the n-propyl acetate solution that is dissolved with PLA, is stirred to evenly dissolving, obtains chelating agent coating solution, wherein CaNa EDTA final concentration in solution is 1.5 mg / mL.

[0106] S3: Add the chelating agent coating solution dropwise into the stent hole, and repeat the dropwise addition after the solvent evaporates until the stent hole is ...

Embodiment 2

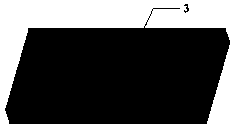

[0109] Please refer to Figure 8 , is a partially enlarged view of a degradable metal stent provided in Example 2 of the present invention. Its preparation method is basically the same as that of Example 1, except that S1: the degradable metal stent is cut into a structure with a through hole in the stent rod, and rapamycin is sprayed on both surfaces of the stent, namely, the outer wall and the inner wall. Coated, drug loaded as polylactic acid.

[0110] In the degradable metal stent prepared according to the above method, the degradable metal stent is a stent with a drug coating, and the drug concentration of rapamycin per unit area of the stent is 10 μg / mm 2 , the concentration of edetate calcium sodium per unit area is 15μg / mm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com