Technology for treating isatis tinctoria

A processing technology, tea blue technology, applied in the direction of centrifuge, etc., can solve the problems of low production efficiency, increased machine power consumption, increased workload of staff, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

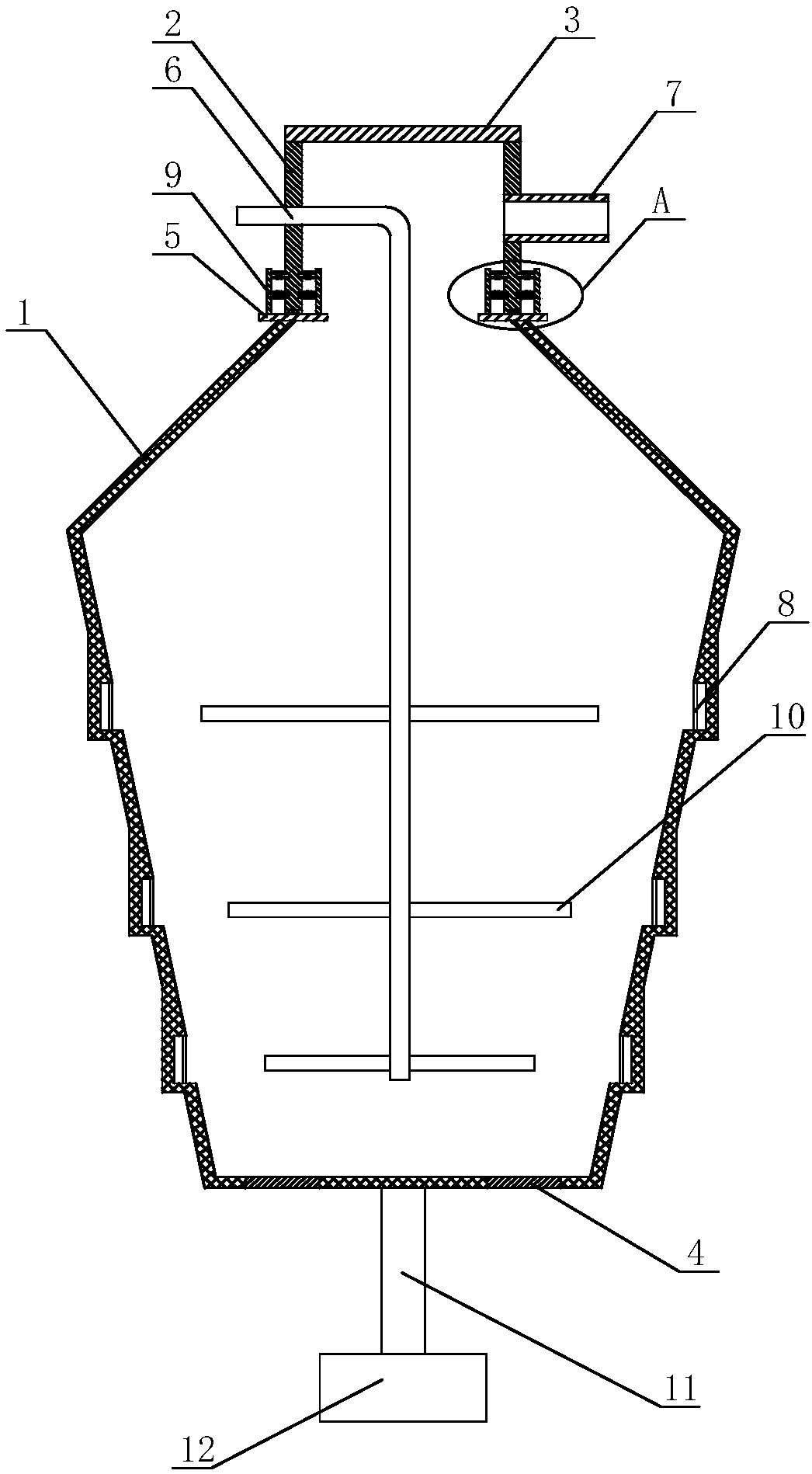

[0051] Such as Figure 1 to Figure 4 The illustrated embodiment includes the following steps:

[0052] (A) separating the roots and leaves of the indigo from the indigo;

[0053] (B) Open the top cover, and pour the Radix Radix and Folium Isatidis obtained from woad into the shell;

[0054] (C) Turn on the motor, the motor drives the shell to rotate around its vertical central axis through the drive rod, and the Radix isatidis and the sand move to the inner wall of the shell under the action of centrifugal force, and finally move along the circumferential direction of the inner wall of the shell on the inner wall of the shell;

[0055] (D) Turn on the blower, a part of the flowing air is blown to the Folium Isatidis accumulated on the bottom surface of the casing through the blast main pipe, and the other part of the flowing air is blown to the inner wall of the casing through the blast branch pipe, so that the moving and spreading Radix isatidis on the inner wall of the casi...

Embodiment 2

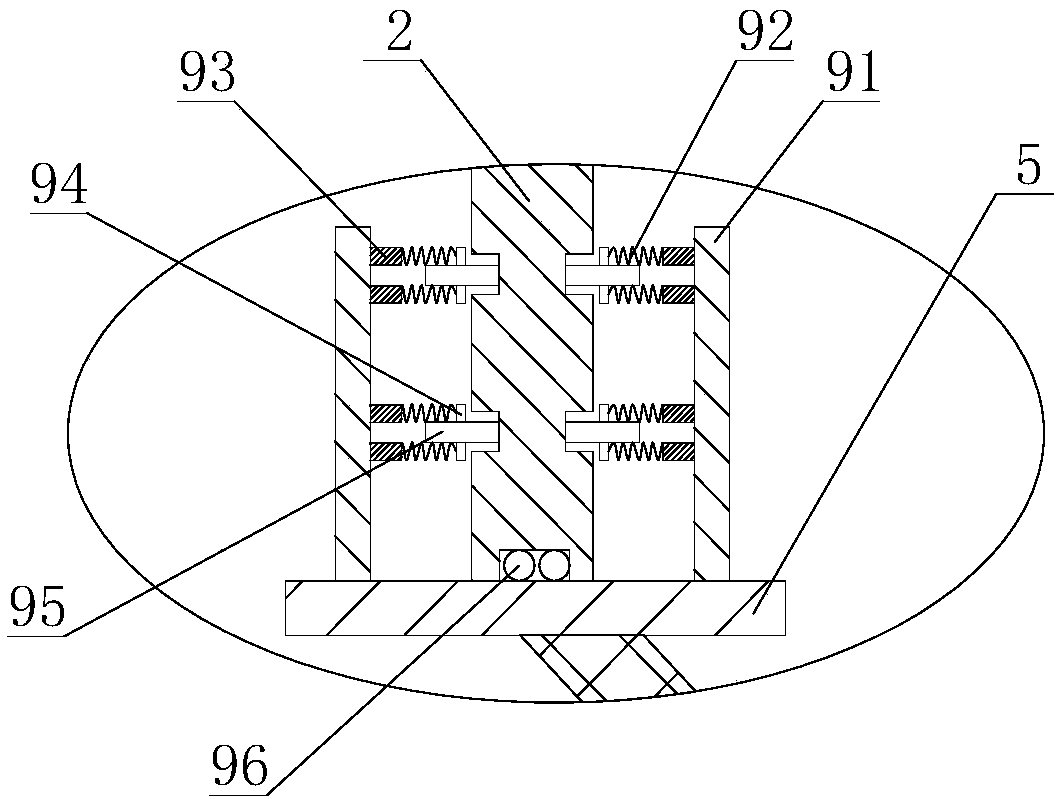

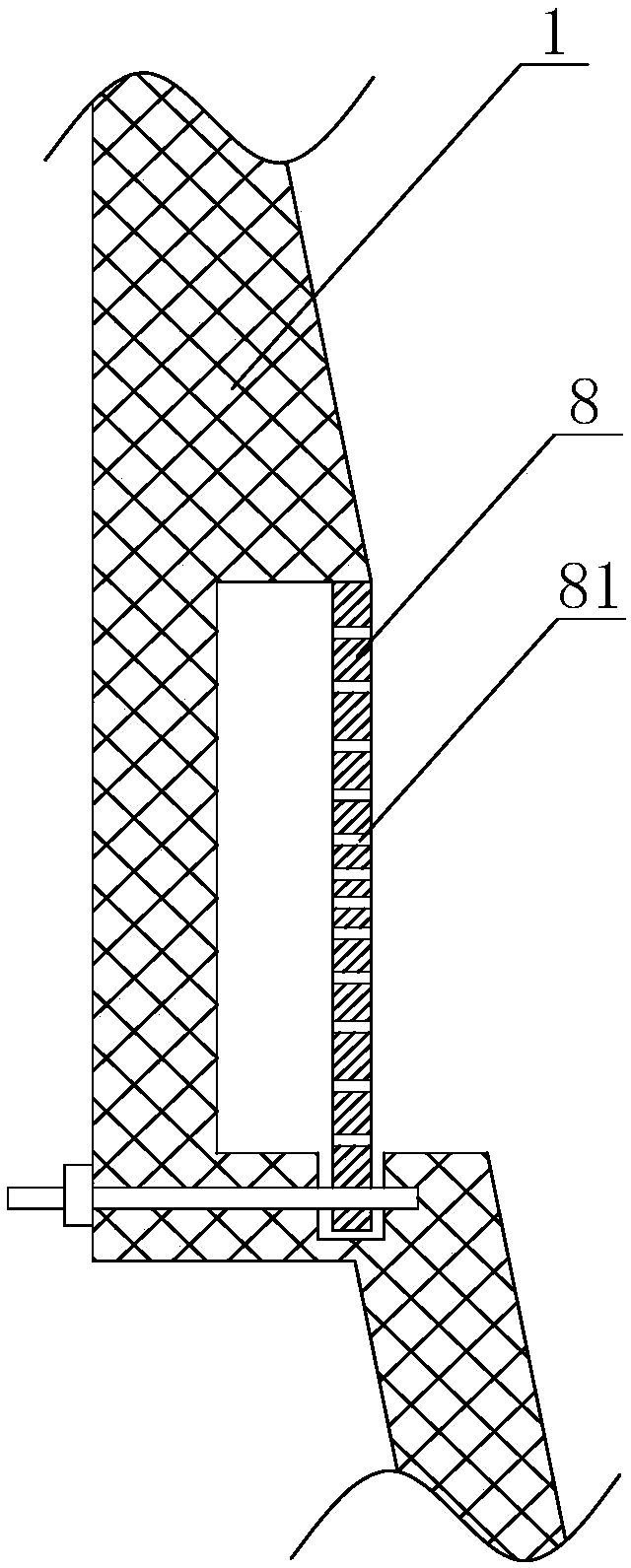

[0062] Such as Figure 4 As shown, on the basis of Example 1, the side wall of the feed cylinder 2 is provided with a roller groove, and the side of the roller 95 squeezes the inner wall of the roller groove; the depth of the roller groove is 1% of the diameter of the roller 95 / 5~1 / 4; the bottom end of the feeding cylinder 2 is provided with a ball groove, and a number of balls 96 are arranged in the ball groove; four support columns 93 are arranged on the fixed plate 91 . The central axis of the air outlet end of the blast main pipe 6 is collinear with the vertical central axis of the shell 1; the outlet end of the blast branch pipe 10 is facing the slag collecting tank; along the direction from the inner wall of the shell 1 to the vertical central axis of the shell 1 , the diameter of the sieve hole 81 gradually increases; the bottom surface of the slag collecting tank is provided with a fixing groove, and the bottom of the sieve plate 8 is fixed in the fixing groove by scr...

Embodiment 3

[0064] On the basis of Example 1, in the step (E), the blowing time is 10-30 minutes; in the step (F), the exhausting time is 10-20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com