Preparation method of fe-al intermetallic compound-based micro-lamination composite material

A technology of intermetallic compounds and composite materials, which is applied in the field of preparation of Fe-Al intermetallic compound-based micro-lamination composite materials, can solve the requirements of very strict vacuum degree and other process conditions, and the layered thickness and uniformity of composite boards are not good. , unsatisfactory distribution of intermetallic compounds, etc., to achieve ideal alloying distribution, easy industrial production, and overall deformation coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Prepare iron and aluminum plates with the same length and width after surface cleaning, wherein the thickness of the iron plate is 1mm, and the thickness of the aluminum plate is 0.27mm; heat the iron plate and aluminum plate in a heating furnace for softening treatment, and then perform surface grinding respectively;

[0043] A plurality of surface-polished iron plates and aluminum plates are alternately stacked together, each aluminum plate is located between two adjacent iron plates, and then all the aluminum plates and iron plates are wrapped and fixed with aluminum foil to obtain a blank; The number of layers is 6 layers, and the total number of layers of the aluminum plate is 5 layers; the thickness of the blank formed after the above operations is 8.2mm;

[0044] Heat the heating furnace to 400±10°C, then place the billet in the heating furnace for 20 minutes, and then take it out for single-pass hot pressing, with a reduction rate of 32%, to obtain a hot-pressed ...

Embodiment 2

[0051] Method is with embodiment 1, and difference is:

[0052] (1) Carry out the third stress relief annealing when the total reduction reaches 79%;

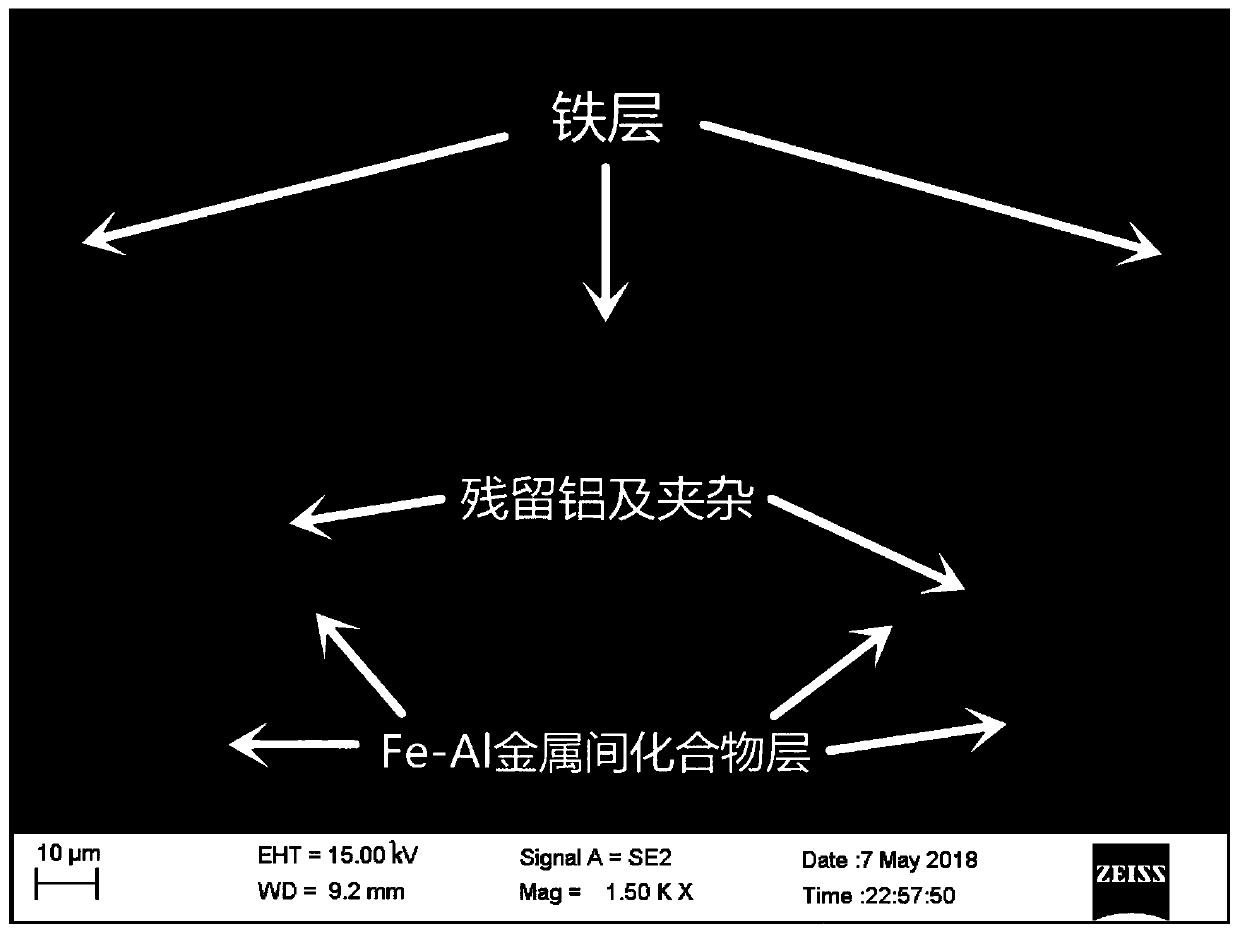

[0053] (6) The heat treatment temperature is 650°C, and the time is 24h; the average thickness of the single-layer Fe-Al intermetallic compound layer is 22 μm; the metallographic micrograph of the Fe-Al intermetallic compound-based micro-laminated composite material is as follows image 3 As shown, the microscopic morphology of the cross-section is as Figure 4 Shown; the tensile strength at a temperature of 600°C is 95MPa, and the high temperature elongation at a temperature of 600°C is 22%.

Embodiment 3

[0055] Method is with embodiment 1, and difference is:

[0056] (1) The thickness of the aluminum plate is 0.25mm;

[0057] (2) The thickness of the blank formed after surface treatment and wrapping and fixing is 7.5mm;

[0058] (3) The reduction rate of single-pass hot pressing is 23%;

[0059] (4) Place the hot-pressed plate in a heating furnace at 450°C for 15 minutes, and the reduction rate of single-pass hot rolling is 38%; the thickness of the hot-rolled plate is 3.58mm;

[0060] (5) The reduction rate of each pass of cold rolling is 4 to 10%. When the total reduction rate reaches 58%, the first stress relief annealing is carried out, and when the total reduction rate reaches 74%, the second stress relief is performed. Annealing, when the total reduction rate reaches 79%, carry out the third stress relief annealing, when the total reduction rate reaches 87%, complete cold rolling;

[0061] (6) The heat treatment temperature is 630°C and the time is 16h; the average th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com