A method for producing desulfurization and denitrification activated carbon

A desulfurization and denitrification, activated carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of low adsorption capacity, low desulfurization and denitrification efficiency, and reduced pollutant content, so as to improve the removal rate and avoid cracking Or broken, improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

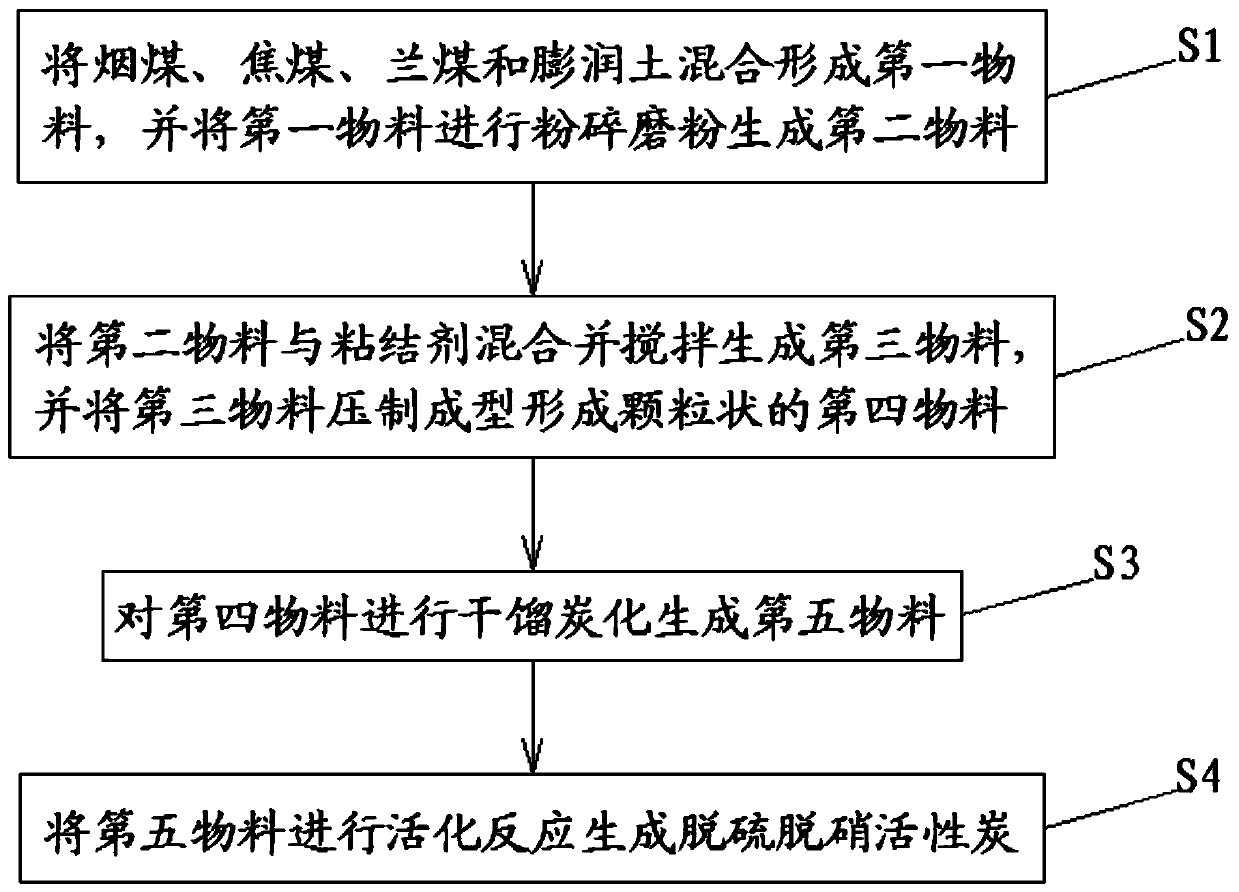

[0026] Such as figure 1 Shown, according to an embodiment of the present invention, a kind of method of producing desulfurization and denitrification activated carbon of the present invention comprises:

[0027] S1. Mixing bituminous coal, coking coal, blue coal and bentonite to form a first material, and pulverizing and pulverizing the first material to form a second material;

[0028] S2. mixing and stirring the second material with the binder to form a third material, and pressing the third material to form a granular fourth material;

[0029] S3. Carrying out dry distillation and carbonization of the fourth material to generate the fifth material;

[0030] S4. Activating the fifth material to generate desulfurization and denitrification activated carbon.

[0031] According to one embodiment of the present invention, in step S1, respectively store bituminous coal, coking coal, blue coal and bentonite in corresponding material bins, and input the materials in each material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com