Titanium-aluminum alloy member having composite infiltration layer, and preparation method thereof, and titanium-aluminum alloy member having diamond coating, and preparation method thereof

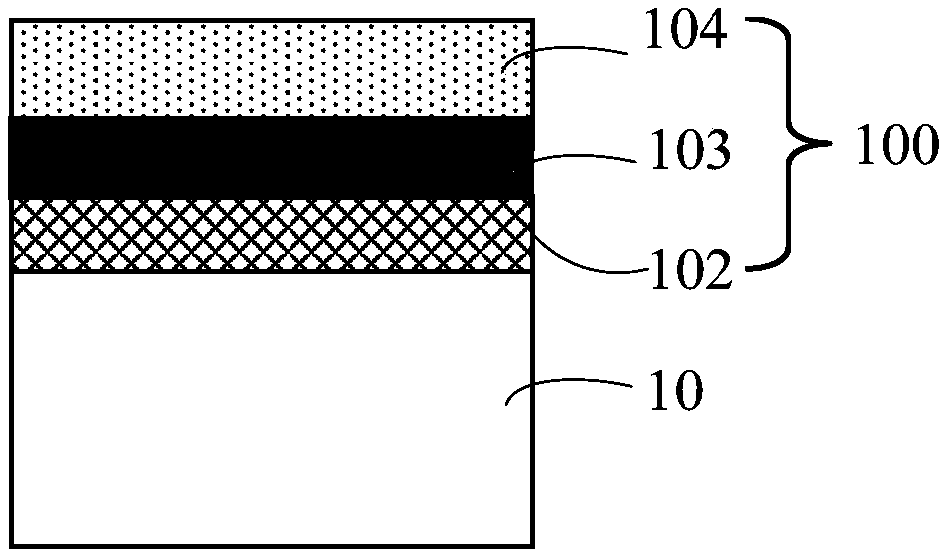

A technology of diamond coating and titanium-aluminum alloy, which is applied in the direction of metal material coating process, coating, superimposed layer plating, etc., can solve the problem of large difference in thermal expansion coefficient, cracks in titanium-aluminum alloy and diamond film, and diamond film peeling off and other problems, to achieve the effect of improving toughness and hardness, increasing service life, and improving resistance to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] A method for preparing a titanium-aluminum alloy part with a composite coating, comprising the following steps:

[0076] Step 1: sequentially use 800#-1500# sandpaper (800 mesh, 1000 mesh, 1200 mesh and 1500 mesh) to polish the titanium-aluminum alloy substrate, and use deionized water to ultrasonically clean after polishing. Then use the corrosive solution to corrode the polished titanium-aluminum alloy substrate for 1 minute, wherein the corrosive solution is prepared with concentrated sulfuric acid and hydrogen peroxide in a volume ratio of 1:10, and then use deionized water to ultrasonically clean it for 10 minutes after corrosion. Minutes, the titanium-aluminum alloy sample after surface pretreatment was obtained.

[0077] Step 2: Composition according to weight percentage: 20% Si powder, 0.5% Zr 2 o 3 powder, 8% NaF powder, the rest is Al 2 o 3 Powder ratio to prepare osmosis agent, all reagents are analytically pure, of which Si powder and Zr 2 o 3 The part...

Embodiment 2

[0086] A method for preparing a titanium-aluminum alloy part with a diamond coating, comprising the following steps:

[0087] Step 1: Use 800#-1500# sandpaper to polish the titanium-aluminum alloy substrate in sequence, and use deionized water to clean it ultrasonically after grinding. Then use the corrosive solution to corrode the polished titanium-aluminum alloy substrate for 30 seconds, wherein the corrosive solution is prepared with concentrated sulfuric acid and hydrogen peroxide according to the volume ratio of 1:10, and then use deionized water to ultrasonically clean it for 10 seconds. Minutes, the titanium-aluminum alloy sample after surface pretreatment was obtained.

[0088] Step 2: Composition according to weight percentage: 15% Si powder, 1% Zr 2 o 3 powder, 8% NaF powder, the rest is Al 2 o 3 The ratio of the powder to prepare the penetrating agent, all reagents are analytically pure, wherein the particle size of Si powder and yttrium oxide is less than or eq...

Embodiment 3

[0097] A method for preparing a titanium-aluminum alloy part with a diamond coating, comprising the following steps:

[0098] Step 1: Use 800#-1500# sandpaper to polish the titanium-aluminum alloy substrate in sequence, and use deionized water to clean it ultrasonically after grinding. Then use the corrosion solution to corrode the polished titanium-aluminum alloy substrate for 2 minutes, wherein the corrosion solution is prepared with concentrated sulfuric acid and hydrogen peroxide according to the volume ratio of 1:10, and use deionized water to ultrasonically clean it for 10 minutes after corrosion. Minutes, the titanium-aluminum alloy sample after surface pretreatment was obtained.

[0099] Step 2: Composition according to weight percentage: 10% Si powder, 3% Zr 2 o 3 powder, 5% NaF powder, the rest is Al 2 o 3 Powder ratio to prepare osmosis agent, all reagents are analytically pure, of which Si powder and Zr 2 o 3 The particle size of the powder is less than or eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com