Photoresist removing solution and photoresist removing method

A photoresist and removal solution technology, which is applied in optics, photomechanical equipment, photosensitive material processing, etc., to achieve the effects of saving cost, improving removal effect, and improving process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

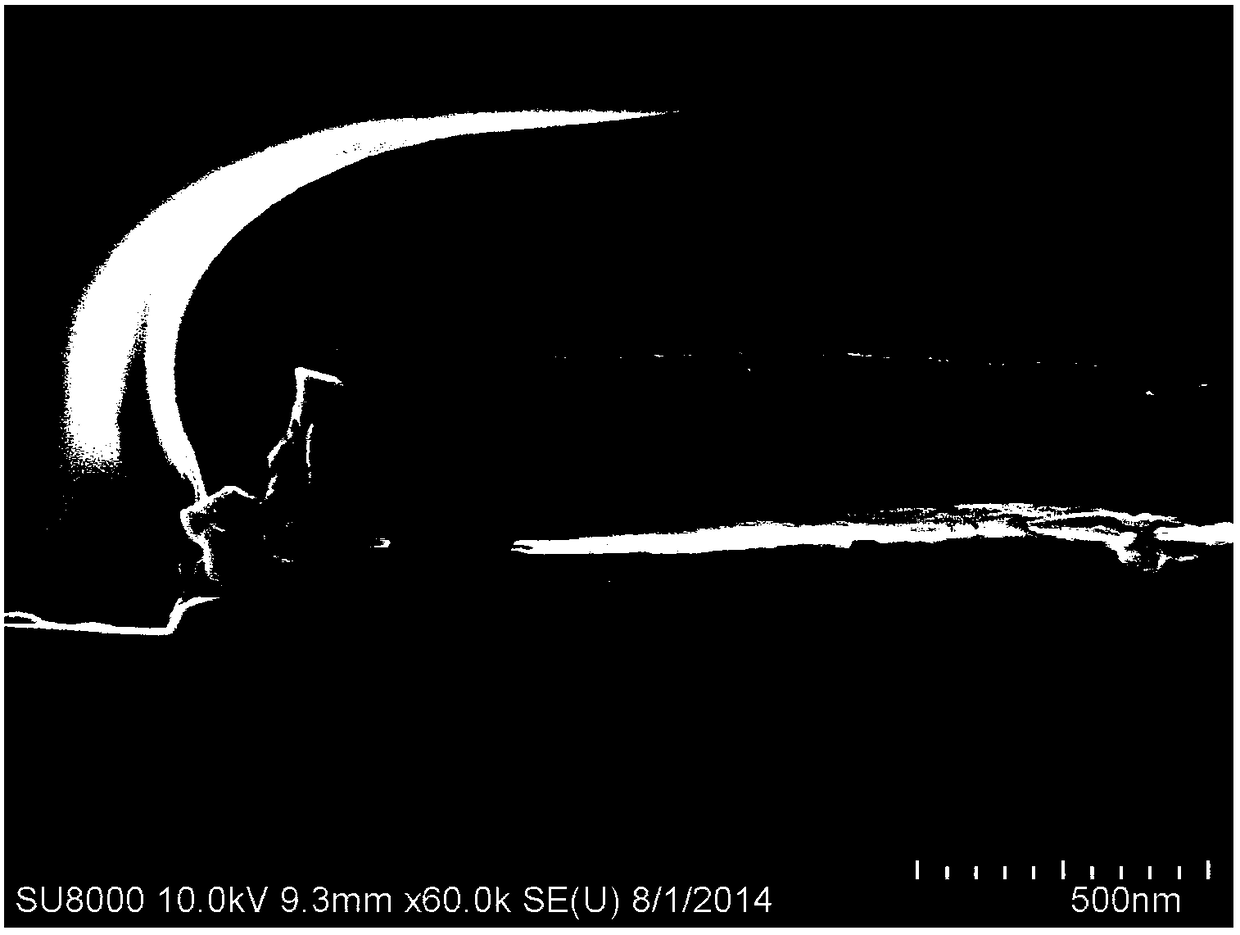

Image

Examples

Embodiment Construction

[0032] The present invention will be further described through several examples below. The following examples are just examples of the present invention, and the content of the present invention is not limited to the following examples. In the following examples, the chemical liquid used is electronic grade, wherein the mass concentration of ammonia water is 25-28%. For the convenience of calculation, in the following examples, the mass concentration of ammonia water is calculated as 28%. In the following examples, the preparation method of the test wafer used to test the removal effect is as follows: the positive photoresist (model AZ701 model AZ701) that is currently in use is coated with a thickness of 1 micron on the entire surface of the wafer using a rotating or sliding device. , AZ Electronics Materials Group (AZ Electronics Materials)), use a hot plate or an oven to perform pre-baking at a temperature of about 150°C, and then expose different wafers using photomasks wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com