Dust removal heat exchange white elimination device and system

A whitening and equipment technology, applied in the direction of electrostatic effect separation, solid separation, and dispersed particle separation, etc., can solve the problems that the use of space cannot be fully utilized, affect the stability of system operation, and heat exchange tubes are easy to pile up dust, etc., to achieve water vapor The effects of content reduction, flow rate reduction, and floor area reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

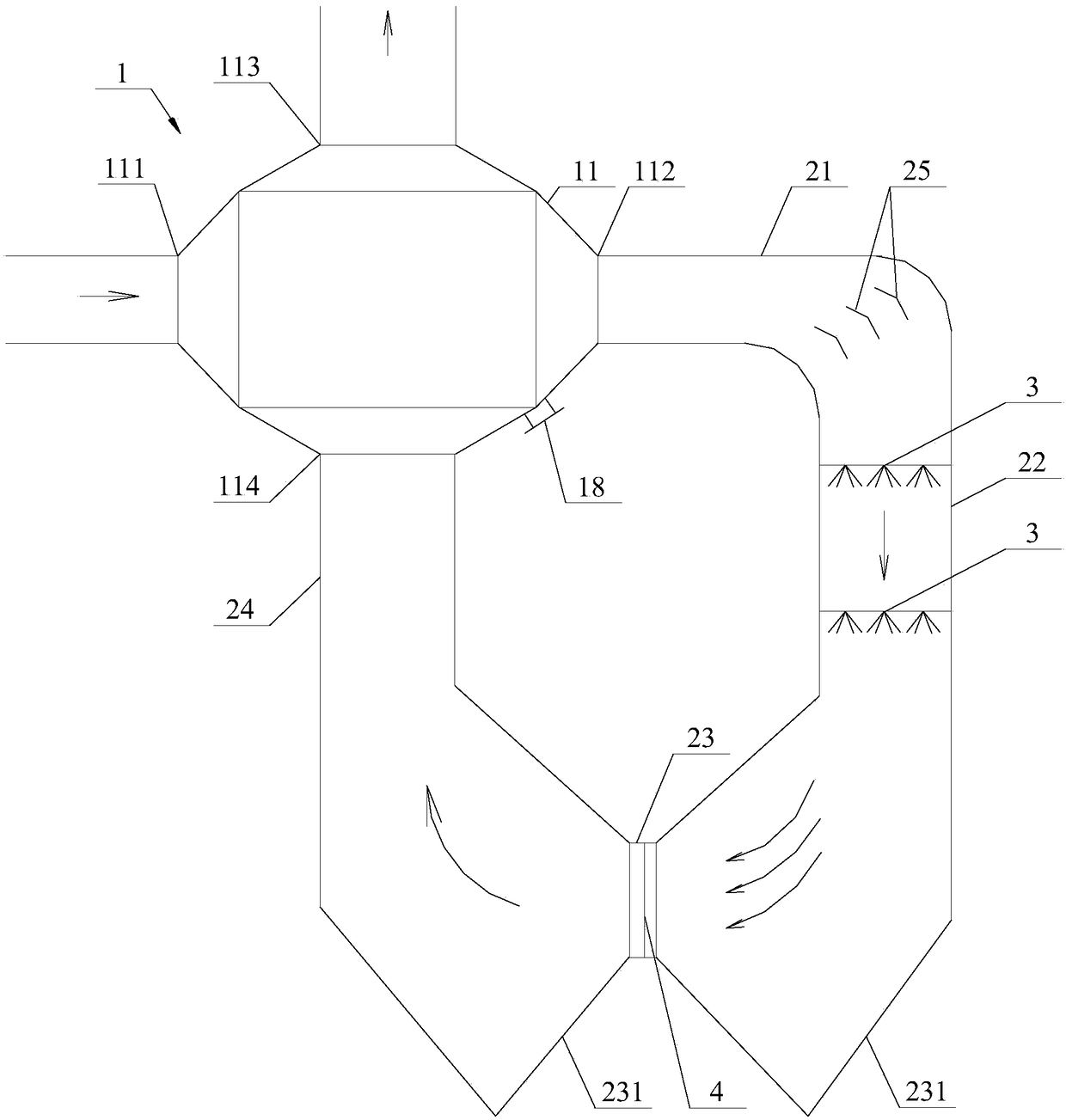

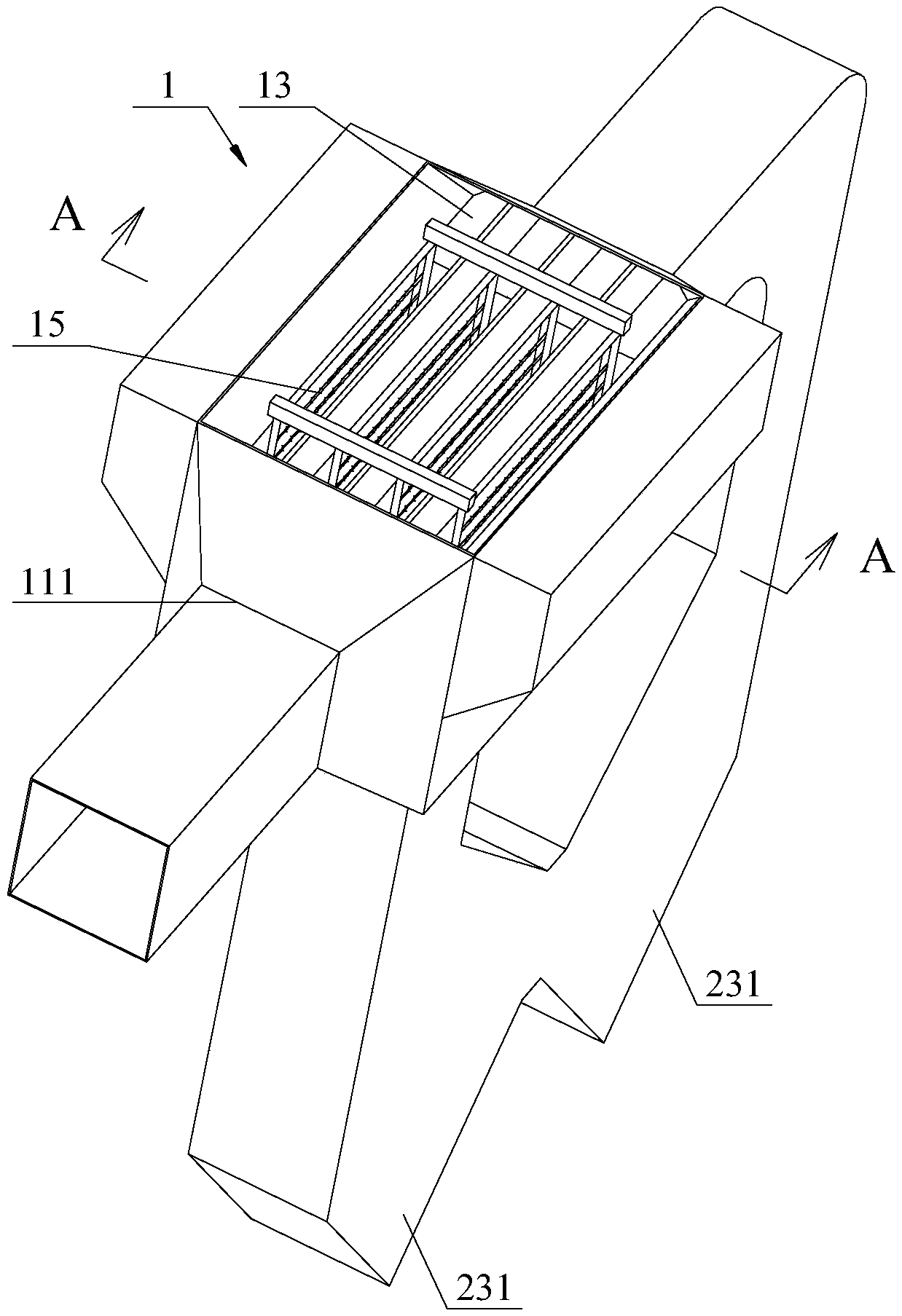

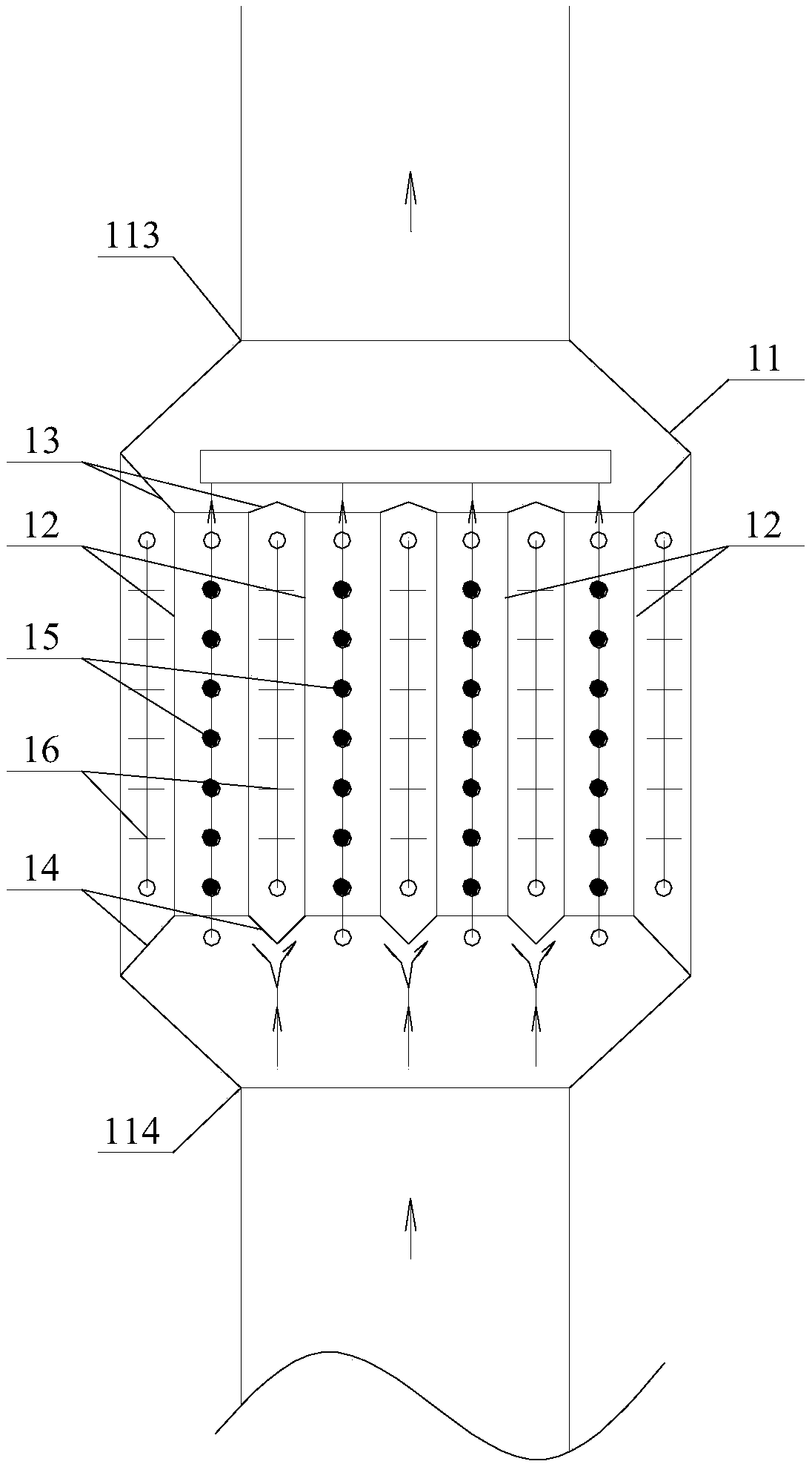

[0034] The core of the dust removal, heat exchange and whitening system provided in this embodiment is to make full use of the internal space and highly integrate the functional components of dust removal and whitening. On the basis of reducing the system footprint and equipment manufacturing cost, it has a better energy-saving effect. Without loss of generality, this embodiment uses figure 1 The dust removal, heat exchange and whitening system shown in the figure is the main body of the basic description. It should be understood that the arrangement of the internal circulation treatment flue of the system is not limited to the form shown in the figure, and its parallel flue and vertical flue are not constitutive of this s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com