Anti-fouling carpet and preparation method thereof

A carpet and nanotechnology, applied in carpets, chemical instruments and methods, antifouling/underwater coatings, etc., can solve the problems of easy breeding of harmful microorganisms, poor waterproof and wear resistance, difficult to clean, etc., to achieve excellent self-cleaning Performance, reduce the growth of harmful microorganisms, the effect of not easy to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

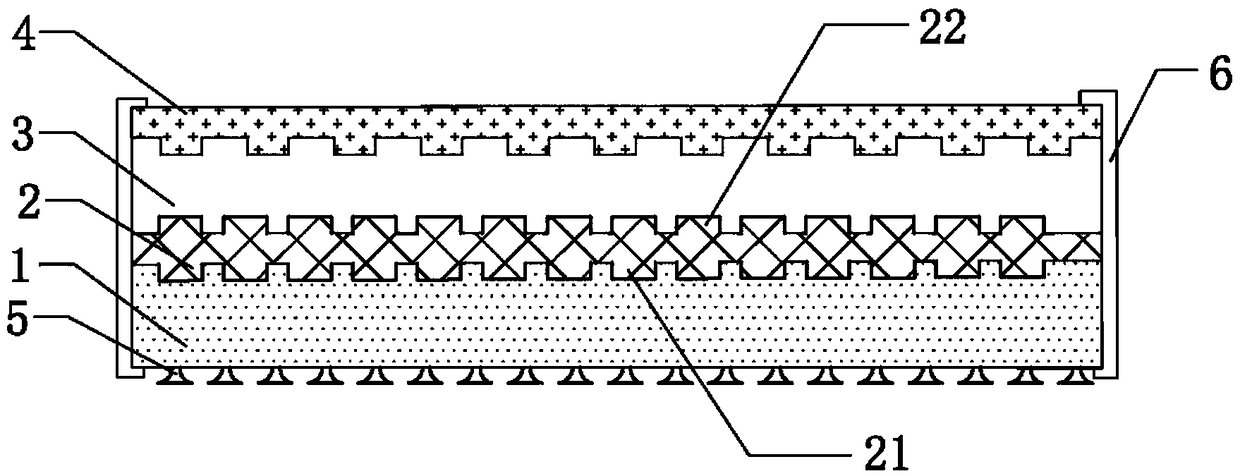

[0035] In this embodiment, an anti-fouling carpet includes a waterproof layer 1, a hot-melt adhesive layer 2, a wear-resistant layer 3, and nano-TiO 2 Self-cleaning layer 4, the bottom of the waterproof layer 1 is provided with a plurality of anti-skid protrusions 5 arranged at intervals, the upper end of the anti-skid protrusions 5 is connected with the lower surface of the waterproof layer 1, the nano-TiO 2 The self-cleaning layer 4 is made of nano-TiO 2 Made with self-cleaning paint.

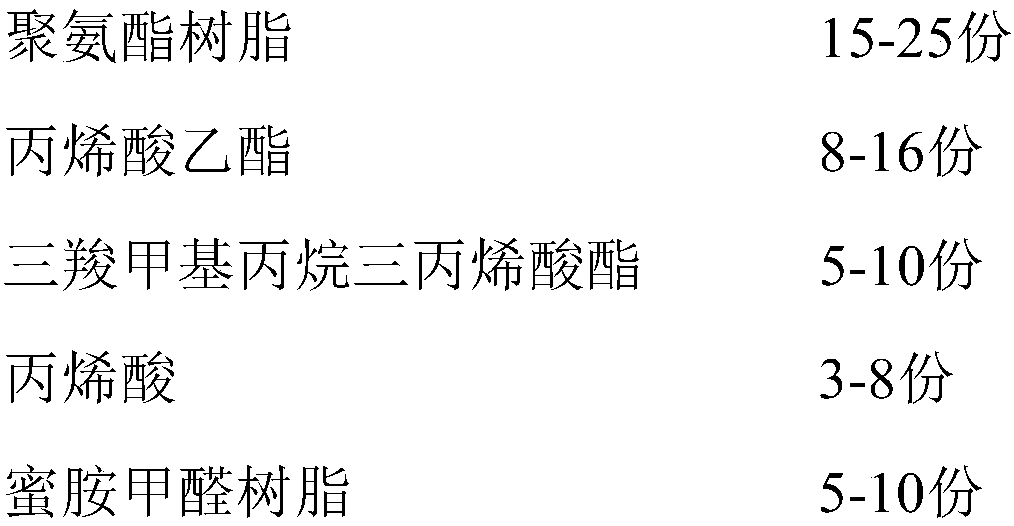

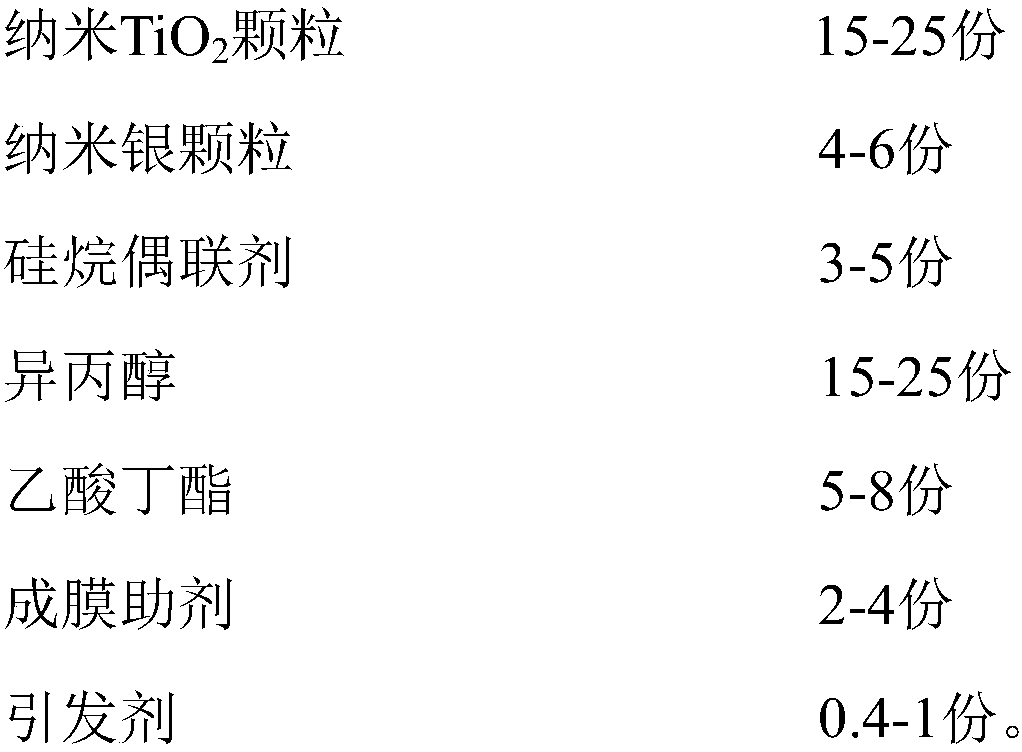

[0036] Further, the nanometer TiO 2 The self-cleaning paint comprises the following raw materials in parts by weight:

[0037]

[0038]

[0039] The nanometer TiO of the present embodiment 2 The preparation method of the self-cleaning coating includes the following steps: adding various raw material components in proportion, feeding nitrogen, stirring, and cooling to room temperature after complete reaction at 100°C to obtain nano-TiO 2 Self-cleaning paint. The process of the metho...

Embodiment 2

[0055] The difference between this embodiment and embodiment 1 is:

[0056] In this example, the nano-TiO 2 The self-cleaning paint comprises the following raw materials in parts by weight:

[0057]

[0058] The nano-TiO of the embodiment of the present invention 2 The preparation method of the self-cleaning coating includes the following steps: adding various raw material components in proportion, feeding nitrogen, stirring, and cooling to room temperature after complete reaction at 90°C to obtain nano-TiO 2 Self-cleaning paint. The process of the method is simple and efficient, the operation process is easy to control, and is beneficial to industrial production.

[0059] Further, the initiator is composed of benzoyl peroxide and azodiisopropylimidazoline hydrochloride with a mass ratio of 1:2.

[0060] Further, the hot-melt adhesive layer 2 is made of hot-melt adhesive, and the hot-melt adhesive includes the following raw materials in parts by weight:

[0061]

[...

Embodiment 3

[0069] The difference between this embodiment and embodiment 1 is:

[0070] In this example, the nano-TiO 2 The self-cleaning paint comprises the following raw materials in parts by weight:

[0071]

[0072] The nano-TiO of the embodiment of the present invention 2 The preparation method of the self-cleaning coating includes the following steps: adding various raw material components in proportion, feeding nitrogen, stirring, and after the reaction is complete at 110 ° C, cooling to room temperature to obtain nano-TiO 2 Self-cleaning paint. The process of the method is simple and efficient, the operation process is easy to control, and is beneficial to industrial production.

[0073] Further, the initiator is benzoyl peroxide.

[0074] Further, the hot-melt adhesive layer 2 is made of hot-melt adhesive, and the hot-melt adhesive includes the following raw materials in parts by weight:

[0075]

[0076] The preparation method of the hot-melt adhesive comprises the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com