A kind of preparation method of tetrasodium aspartic acid diacetate

A technology of tetrasodium aspartate diacetate and aspartic acid, which is applied in the preparation of organic compounds, cyanide reaction preparation, chemical instruments and methods, etc., can solve the problems of low yield and the like, and improve the reaction yield , The effect of stable product quality and short reaction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

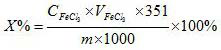

Examples

Embodiment 1

[0028] (1) Add 201.5g of L-aspartic acid, 100g of 30% aqueous sodium hydroxide solution and 75g of deionized water into the reaction kettle, stir and mix evenly, and the neutralization degree of L-aspartic acid is about 50%;

[0029] (2) Dissolve 315g of chloroacetic acid in 220g of deionized water, and put it into a constant pressure dropping funnel for later use;

[0030] (3) 655g mass percentage composition is 45% sodium hydroxide aqueous solution and is put into another constant pressure dropping funnel for subsequent use;

[0031] (4) Raise the temperature of the reactor system to 85°C, and add dropwise the aqueous solution of chloroacetic acid in step (2) and the liquid caustic soda in step (3), and control the rate of addition so that the temperature of the reaction system is at 85-90°C and pH The value is maintained at 10.5-11, and the dropwise addition is completed in 1.5 hours; while the dropwise addition reaction is started, under the negative pressure condition of ...

Embodiment 2

[0035] (1) Add 134g of L-aspartic acid, 107g of 30% sodium hydroxide aqueous solution and 50g of deionized water into the reaction kettle, stir and mix evenly, and the neutralization degree of L-aspartic acid is about 80%;

[0036] (2) Dissolve 200g of chloroacetic acid in 141g of deionized water and put it into a constant pressure dropping funnel for later use;

[0037] (3) 460g mass percentage content is 40% sodium hydroxide aqueous solution and is put into another constant pressure dropping funnel for subsequent use;

[0038] (4) Raise the temperature of the reactor system to 80°C, and at the same time add dropwise the aqueous solution of chloroacetic acid in step (2) and the liquid caustic soda in step (3), and control the rate of addition so that the temperature of the reaction system is at 80-85°C and the pH The value is maintained at 10-10.5, and the dropwise addition is completed in 1 hour; at the same time as the dropwise addition reaction is started, under the negati...

Embodiment 3

[0042] (1) Add 134g of L-aspartic acid, 80g of 30% sodium hydroxide aqueous solution and 50g of deionized water into the reaction kettle, stir and mix evenly, and the neutralization degree of L-aspartic acid is about 60%;

[0043] (2) Dissolve 219.5g of chloroacetic acid in 155g of deionized water, and put it into a constant pressure dropping funnel for later use;

[0044] (3) 445g mass percentage composition is that 45% sodium hydroxide aqueous solution is packed into another constant pressure dropping funnel for subsequent use;

[0045] (4) Raise the temperature of the reactor system to 85°C, and add dropwise the aqueous solution of chloroacetic acid in step (2) and the liquid caustic soda in step (3), and control the rate of addition so that the temperature of the reaction system is at 85-90°C and pH The value is maintained at 11-11.5, and the dropwise addition is completed in 1 hour; while the dropwise addition reaction is started, under the negative pressure condition of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com