A kind of photosensitive resin composition and application thereof for photocuring 3D printing

A 3D printing, photosensitive resin technology, applied in the field of 3D printing, can solve the molecular structure requirements of the photosensitive resin composition, and it is difficult to obtain high-quality casting products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

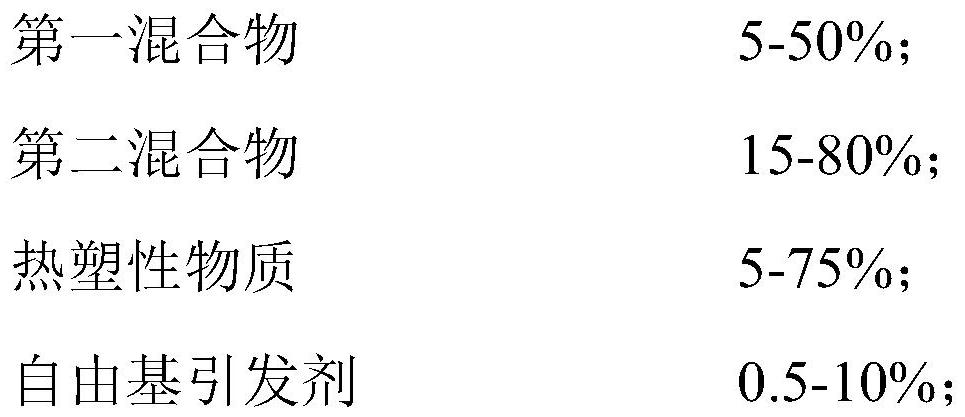

Method used

Image

Examples

Embodiment 1

[0034] A photocurable 3D printing photosensitive resin composition that can be used for investment casting, comprising 5wt% ethoxylated trimethylolpropane triacrylate, 15wt% ethoxylated bisphenol A diacrylate, 50wt% aliphatic urethane acrylate ( Functionality 3), 20 wt% glyceryl stearate, 10 wt% TEPO (2,4,6-trimethylbenzoyl-ethoxy-phenylphosphine oxide).

[0035] The manufacturing process of the composition is as follows: after being stirred by an emulsifier for 1 hour, vacuum defoaming treatment is carried out.

[0036] The liquid composition has a wavelength of 405nm and an energy value of 6500uW / cm 2 After the surface exposure and molding of each layer with a printing time of 3s under the light source, after cleaning, the baking residual rate is less than 0.5wt%.

Embodiment 2

[0038] A photocurable 3D printing photosensitive resin composition that can be used for investment casting, comprising 50wt% ethoxylated pentaerythritol triacrylate, 21wt% polyethylene glycol (200) acrylate, 23.5wt% aliphatic urethane acrylate (functional Degree 2), 5wt% polyethylene wax powder, 0.5wt% TPO (2,4,6-trimethylbenzoyl-diphenylphosphine oxide).

[0039] The manufacturing process of the composition is as follows: after being stirred by an emulsifier for 1 hour, vacuum defoaming treatment is carried out.

[0040] The liquid composition has a wavelength of 405nm and an energy value of 6500uW / cm 2 After the surface exposure and molding of each layer with a printing time of 4s under the light source, after cleaning, the baking residual rate is less than 0.5wt%.

Embodiment 3

[0042] A photocurable 3D printing photosensitive resin composition that can be used for investment casting, comprising 10wt% ethoxylated pentaerythritol acrylate, 80wt% polyethylene glycol (1000) acrylate, 9wt% polyester polyol, 1wt% 819[ (bis(2,4,6-trimethylbenzoylphenyl)phosphorus oxide)].

[0043] The manufacturing process of the composition is as follows: after being stirred by an emulsifier for 2 hours, vacuum defoaming treatment is performed.

[0044] The liquid composition has a wavelength of 405nm and an energy value of 6500uW / cm 2 After the surface exposure and molding of each layer with a printing time of 5s under the light source, after cleaning, the baking residual rate is less than 0.5wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com