Novel special material for rubber bellows and preparation method thereof

A corrugated tube and rubber technology, which is applied in the field of special materials for new rubber corrugated tubes and its preparation, can solve the problems of chemical sensitivity, inability to be exposed, and poor performance of instruments such as steel pipes, and achieve strong radiation resistance, improved compatibility, and enhanced The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

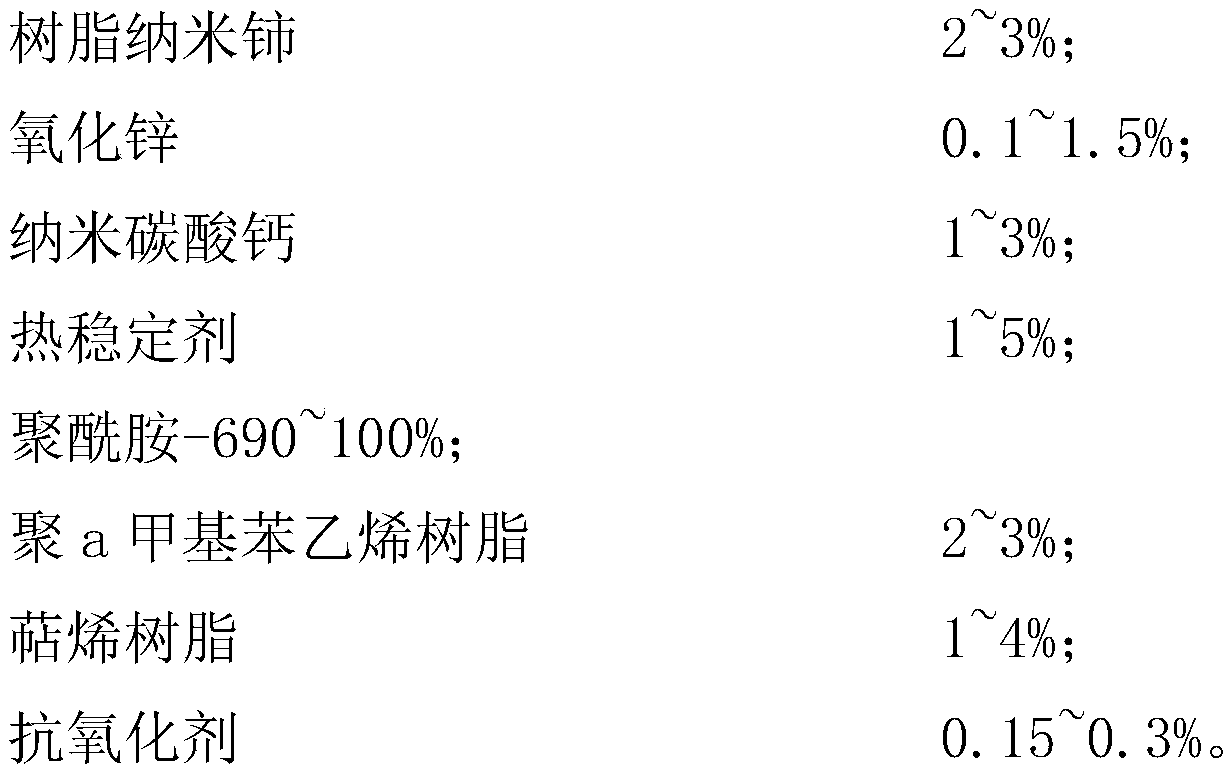

Method used

Image

Examples

Embodiment 1

[0045] 1) Take 90% by weight of polyamide-6 and put it into a reaction kettle, and heat to melt;

[0046] 2) Reactor is heated to 64 DEG C, put into 1% by weight heat stabilizer, then drop into 2% by weight of poly-a-methylstyrene resin and 1% by weight of terpene resin; stir for 4 hours, wait for another completely miscible;

[0047] 3) Put 1% by weight of nano-calcium carbonate into the reactor, adjust the temperature to 60° C., stir and disperse at 600 rpm for 3 minutes;

[0048] 4) 2% by weight of resin nano-cerium and 0.1% by weight of zinc oxide are put into the reactor, heated to 100° C., fed with 0.15% by weight of antioxidant, and stirred at 1000 rpm for 20 minutes;

[0049] 5) Continue stirring at a temperature of 120°C. After stirring evenly, it will be automatically cooled. After passing through the vibrating screen, the material will be automatically loaded. The twin-screw extruder will be extruded under high temperature and high pressure. After the product is pu...

Embodiment 2

[0053] 1) Put 100% by weight polyamide-6 into a reaction kettle, and heat until melting;

[0054] 2) Reactor is heated to 107 DEG C, put into 5% by weight heat stabilizer, then drop into 3% by weight of poly-a-methylstyrene resin and 4% by weight of terpene resin; stir for 6 hours, wait until completely miscible;

[0055] 3) Put 3% by weight of nano-calcium carbonate into the reactor, adjust the temperature to 65° C., stir and disperse at 1000 rpm for 5 minutes;

[0056] 4) 3% by weight of resin nano-cerium and 1.5% by weight of zinc oxide are put into the reactor, heated to 110° C., fed with 0.3% by weight of antioxidant, and stirred at 1600 rpm for 30 minutes;

[0057] 5) Continue to stir at a temperature of 150°C. After stirring evenly, it will be automatically cooled. After passing through the vibrating screen, the material will be automatically loaded. It will be extruded by a twin-screw extruder through high temperature and high pressure. After the product is pulled out...

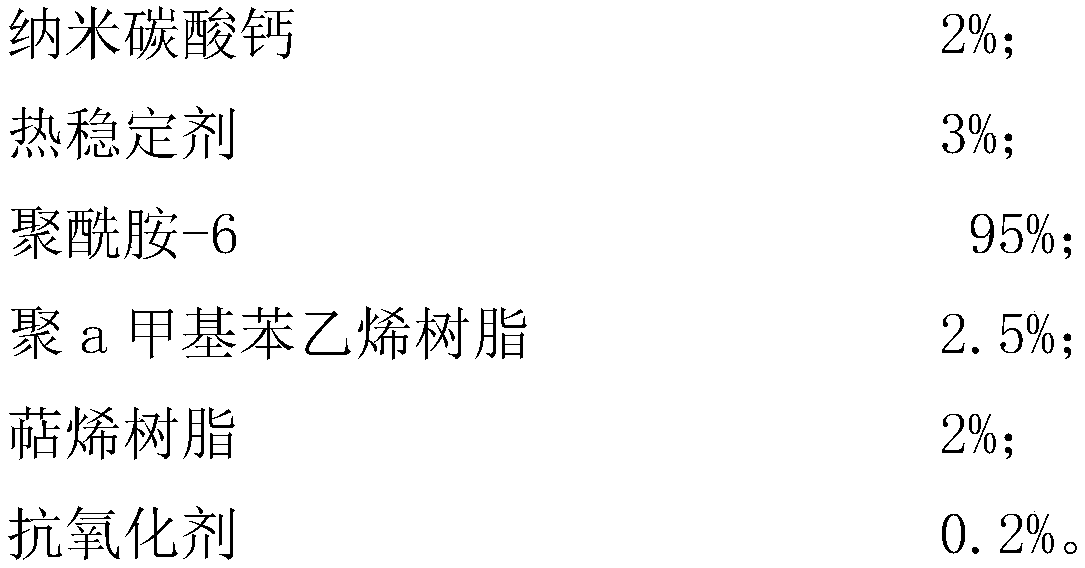

Embodiment 3

[0061] 1) Take 95% by weight of polyamide-6 and put it into a reaction kettle, and heat it until it melts;

[0062]2) The reaction kettle is heated to 100°C, and 3 parts by weight of heat stabilizer are added, followed by 2.5% by weight of poly-a-methylstyrene resin and 4% by weight of terpene resin; stir for 6 hours, and wait until it is completely Miscible;

[0063] 3) 3% by weight of nano-calcium carbonate is put into the reactor to adjust the temperature to 63° C., and stir and disperse at 800 rpm for 4 minutes;

[0064] 4) 2.5% by weight of resin nano-cerium and 0.8% by weight of zinc oxide are put into the reactor, heated to 105° C., fed with 0.2% by weight of antioxidant, and stirred at 1400 rpm for 25 minutes;

[0065] 5) Continue to stir at a temperature of 140°C. After stirring evenly, it will be automatically cooled. After passing through the vibrating screen, it will be automatically loaded. It will be extruded by a twin-screw extruder through high temperature and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com