Domestication method for industrial saccharomyces cerevisiae

A technology of Saccharomyces cerevisiae and Saccharomyces cerevisiae, which is applied in the fields of bioengineering and microorganisms, can solve the problems of limited domestication and cultivation time, inability to improve the high-concentration ethanol tolerance of yeast strains, etc. Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

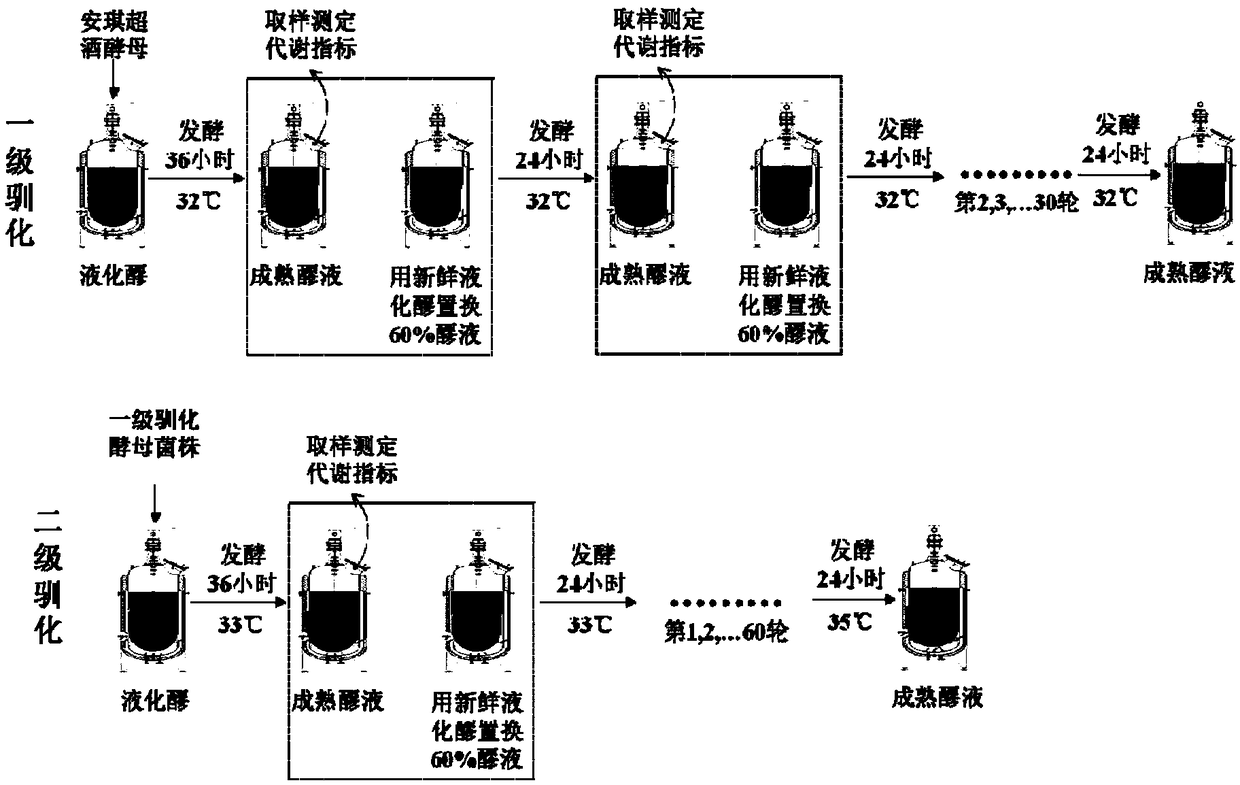

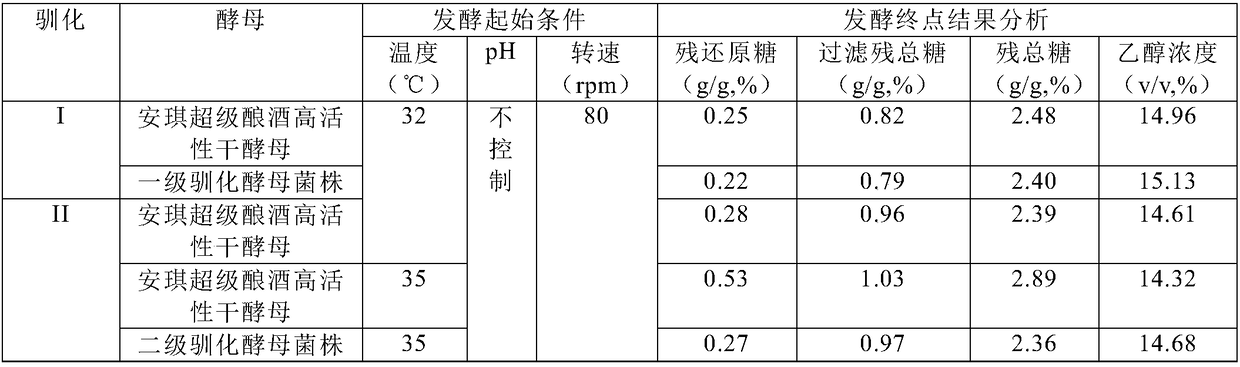

Method used

Image

Examples

Embodiment 1

[0086] Angel super brewer's high-activity dry yeast (production batch number: cy80081) was purchased from Angel Yeast Co., Ltd. The substrate used in the domestication process and the cultivation of distiller's yeast is cornmeal liquefied mash, with a dry solid content of 30 wt%. The acclimatization process was carried out in a bench-top fermenter (Shanghai Baoxing, BIOTECH2JG) with a total volume of 3L.

[0087] Corn liquefaction mash is made by mixing corn flour with water in a mass ratio of 1:2 to form a uniform slurry, then heating and precooking, so that the starch absorbs water and swells, heating to 85±1°C, staying for 30 minutes, adding amylase at temperature It was obtained by liquefaction at 85°C for 3 hours. The corn liquefied mash contains 125,000 U / kg (mash) glucoamylase, 0.35 million U / kg (mash) acid protease and 3 ppm penicillin.

[0088] (1) Weigh 10g of Angel Super Saccharomyces cerevisiae high active dry yeast, add 200mL of sterile water, activate at 30°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com