Lightweight high-entropy alloy with high strength and high plasticity and preparation method thereof

A technology of high-entropy alloy and high plasticity, which is applied in the field of light-weight high-entropy alloy and its preparation, can solve the problems of low density, high hardness, limited application, severe plastic sacrifice, etc., and achieve easy acquisition, simple operation and huge application potential Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

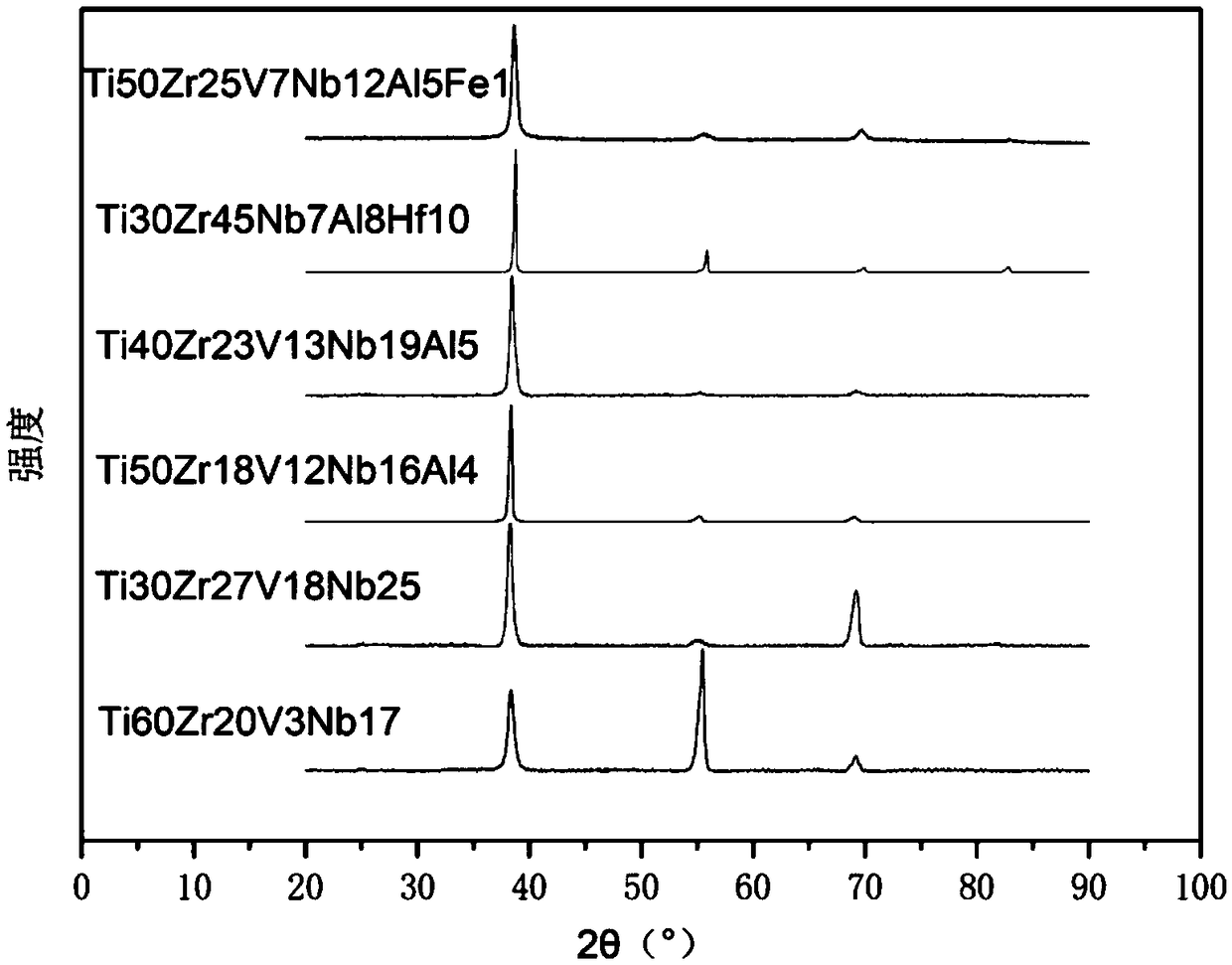

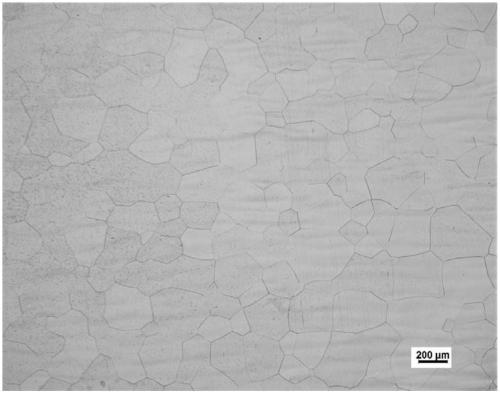

Embodiment 1

[0034] Lightweight Ti with high strength and high plasticity 60 Zr 20 V 3 Nb 17 The preparation steps of high entropy alloy are as follows:

[0035] Step 1: Use elemental Ti, Zr, V and Nb with a purity of not less than 99.7wt% as raw materials, first use a grinding wheel to remove the scale on the surface of the raw materials, and then use absolute ethanol for ultrasonic vibration cleaning, and according to the atomic percentage Ti :Zr:V:Nb=60:20:3:17 Weigh out clean raw materials with a total mass of (70±0.01)g;

[0036] Step 2: Put the weighed raw materials into the water-cooled copper crucible of the high-vacuum non-consumable arc melting furnace in order of melting point from low to high, and then vacuumize until the vacuum degree in the melting furnace reaches 2.5×10 -3 After Pa, fill in argon as a protective gas; before melting the alloy, first melt the pure titanium metal ingot to further reduce the oxygen content in the furnace cavity of the melting furnace, and th...

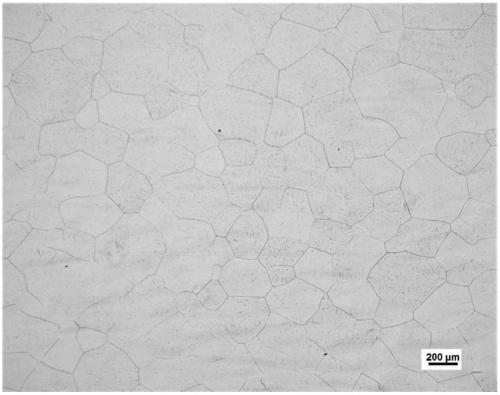

Embodiment 2

[0040] Lightweight Ti with high strength and high plasticity 30 Zr 27 V 18 Nb 25 The preparation steps of high entropy alloy are as follows:

[0041] Step 1: Use elemental Ti, Zr, V and Nb with a purity of not less than 99.7wt% as raw materials, first use a grinding wheel to remove the scale on the surface of the raw materials, and then use absolute ethanol for ultrasonic vibration cleaning, and according to the atomic percentage Ti :Zr:V:Nb=30:27:18:25 Weigh out clean raw materials with a total mass of (70±0.01)g;

[0042] Step 2: Put the weighed raw materials into the water-cooled copper crucible of the high-vacuum non-consumable arc melting furnace in order of melting point from low to high, and then vacuumize until the vacuum degree in the melting furnace reaches 2.5×10 -3 After Pa, fill in argon as a protective gas; before melting the alloy, melt the pure titanium metal ingot to further reduce the oxygen content in the furnace cavity of the melting furnace, and then c...

Embodiment 3

[0046] Lightweight Ti with high strength and high plasticity 50 Zr 18 V 12 Nb 16 Al 4 The preparation steps of high entropy alloy are as follows:

[0047] Step 1: Use elemental Ti, Zr, V, Nb and Al with a purity of not less than 99.7wt% as raw materials, first use a grinding wheel to remove the scale on the surface of the raw materials, and then use absolute ethanol for ultrasonic vibration cleaning, and according to the atomic Percentage Ti:Zr:V:Nb:Al=50:18:12:16:4 Weigh out the clean raw material whose total mass is (70±0.01)g;

[0048] Step 2: Put the weighed raw materials into the water-cooled copper crucible of the high-vacuum non-consumable arc melting furnace in order of melting point from low to high, and then vacuumize until the vacuum degree in the melting furnace reaches 2.5×10 -3 After Pa, fill in argon as a protective gas; before melting the alloy, melt the pure titanium metal ingot to further reduce the oxygen content in the furnace cavity of the melting fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com