Temperature control system

A technology of temperature control system and control components, which is applied in the direction of electrical components, thermal switch components, power devices inside the switch, etc., can solve the problems of high maintenance cost, high technical requirements, high price, etc., and achieve high control accuracy, The effect of wide control range and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

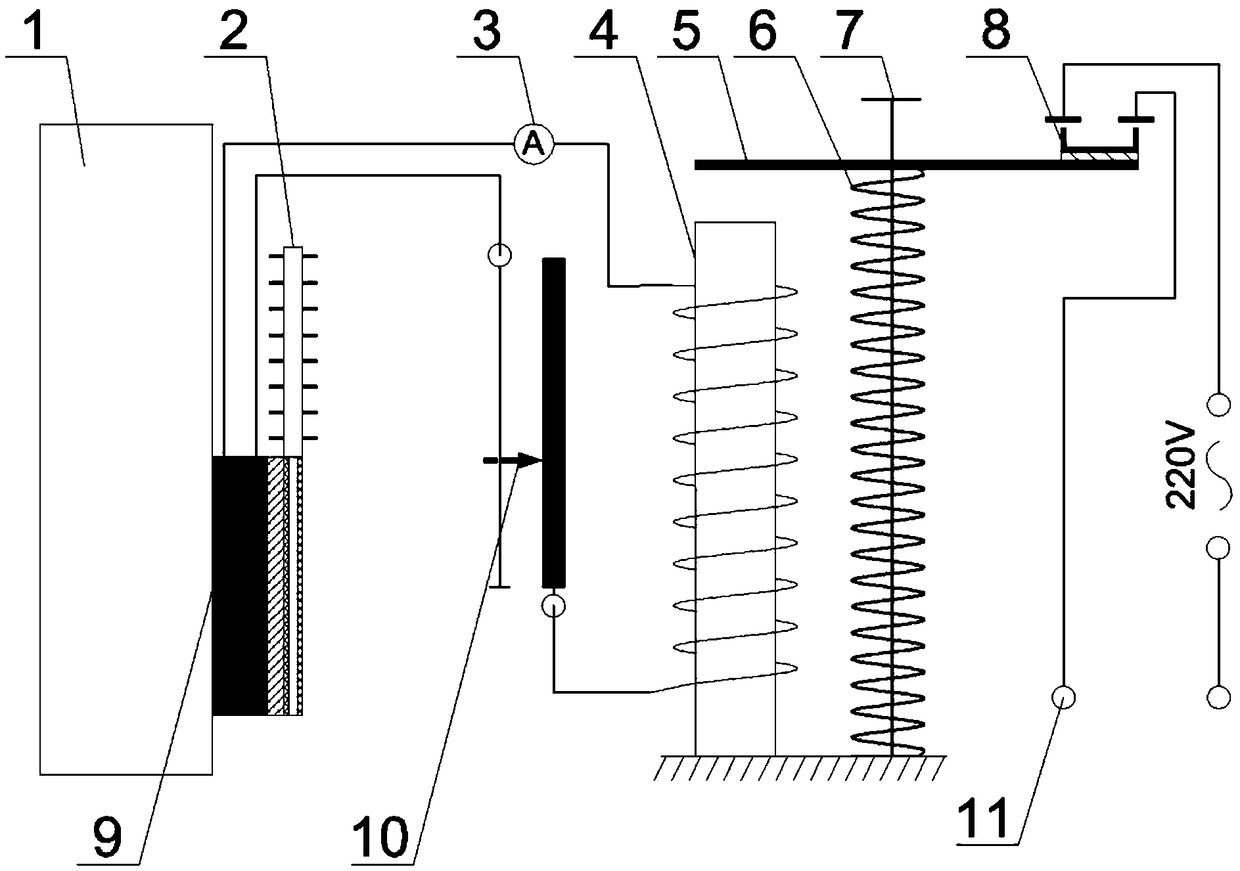

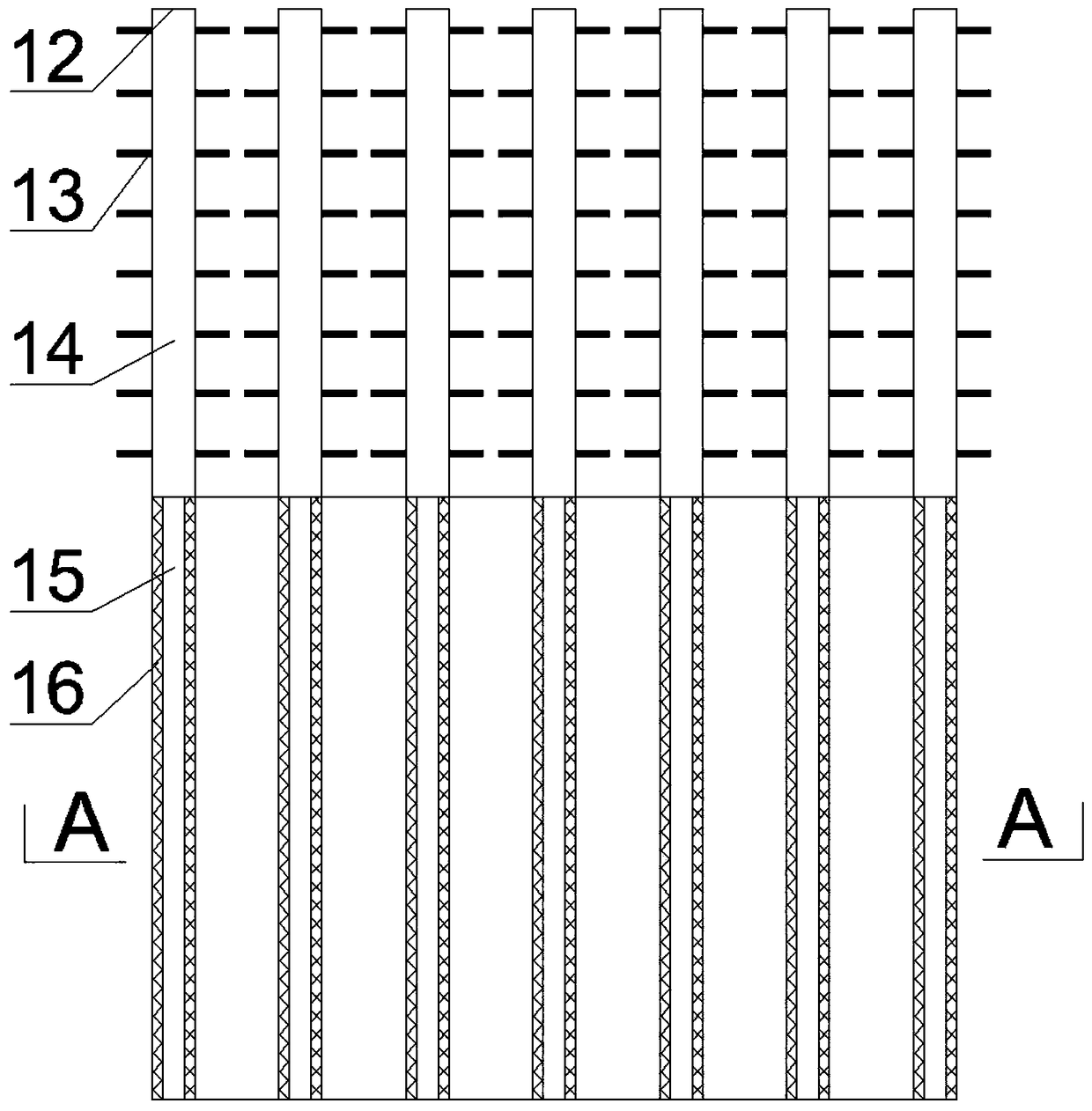

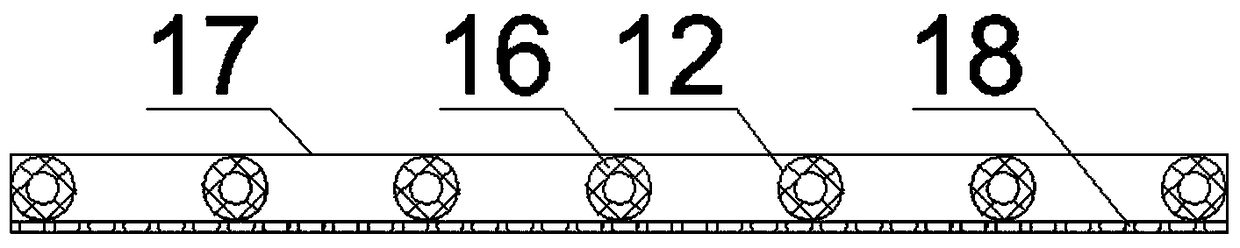

[0027] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention includes a thermoelectric chip 9 , an electromagnet 4 , an armature 5 and a vacuum heat pipe cooling system 2 .

[0028] The hot end of the thermoelectric chip 9 is placed at the place to be detected 1, and the cold end dissipates heat through the vacuum heat pipe system 2. The thermoelectric chip 9 is closed and communicated with the electromagnet 4, and the electromagnet 4 is aligned with the armature 5. The active end is set, and the driven end of the armature 5 is insulated and provided with a control element 8 connected to an external circuit. The control element 8 is a normally closed contact switch, that is, the contact switch is fixed on the driven end of the armature 5 through insulating glue. When the hot end of the thermoelectric generation piece 9 senses that the temperature at the place to be detected reaches the set temperature, the thermoelectric generation piece generates a magn...

Embodiment 2

[0035] Such as Figure 4 As shown, compared with the technical solution in embodiment 1, in this embodiment, the contact switch in embodiment 1 is replaced with an external rheostat, specifically a sliding rheostat for an external circuit. A system that connects the circuit to make real-time corresponding feedback, such as a heating system or a water heater constant temperature control system. After the temperature difference heating plate detects the temperature to be detected, it feeds back to the external circuit in real time, and the external circuit adjusts the power to achieve the effect of constant temperature. Of course, as known by those skilled in the art, the external electrical components in this technical solution are not only contact switches or external sliding rheostats, but also other systems that require feedback based on temperature detection, which are also applicable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com