Sea-islands type composite fiber having excellent moisture absorbability, textured yarn, and fiber structure

A composite fiber and island-in-the-sea technology, which is applied in fiber processing, conjugated synthetic polymer artificial filament, transportation and packaging, etc., can solve the problems of stuffy heat, static electricity, insufficient hygroscopicity, etc., and achieve dissolution inhibition, less fluff, The effect of less uneven coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

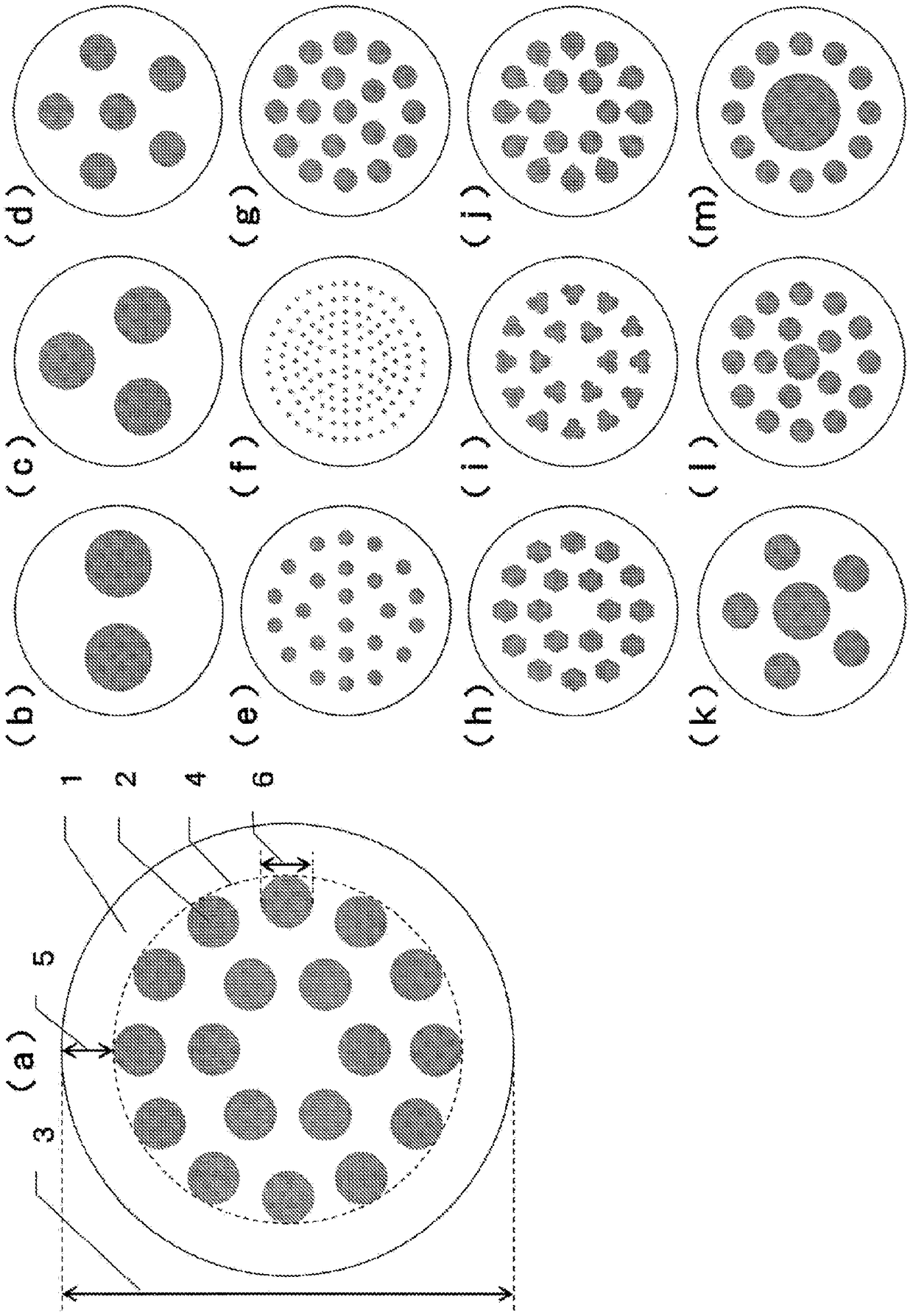

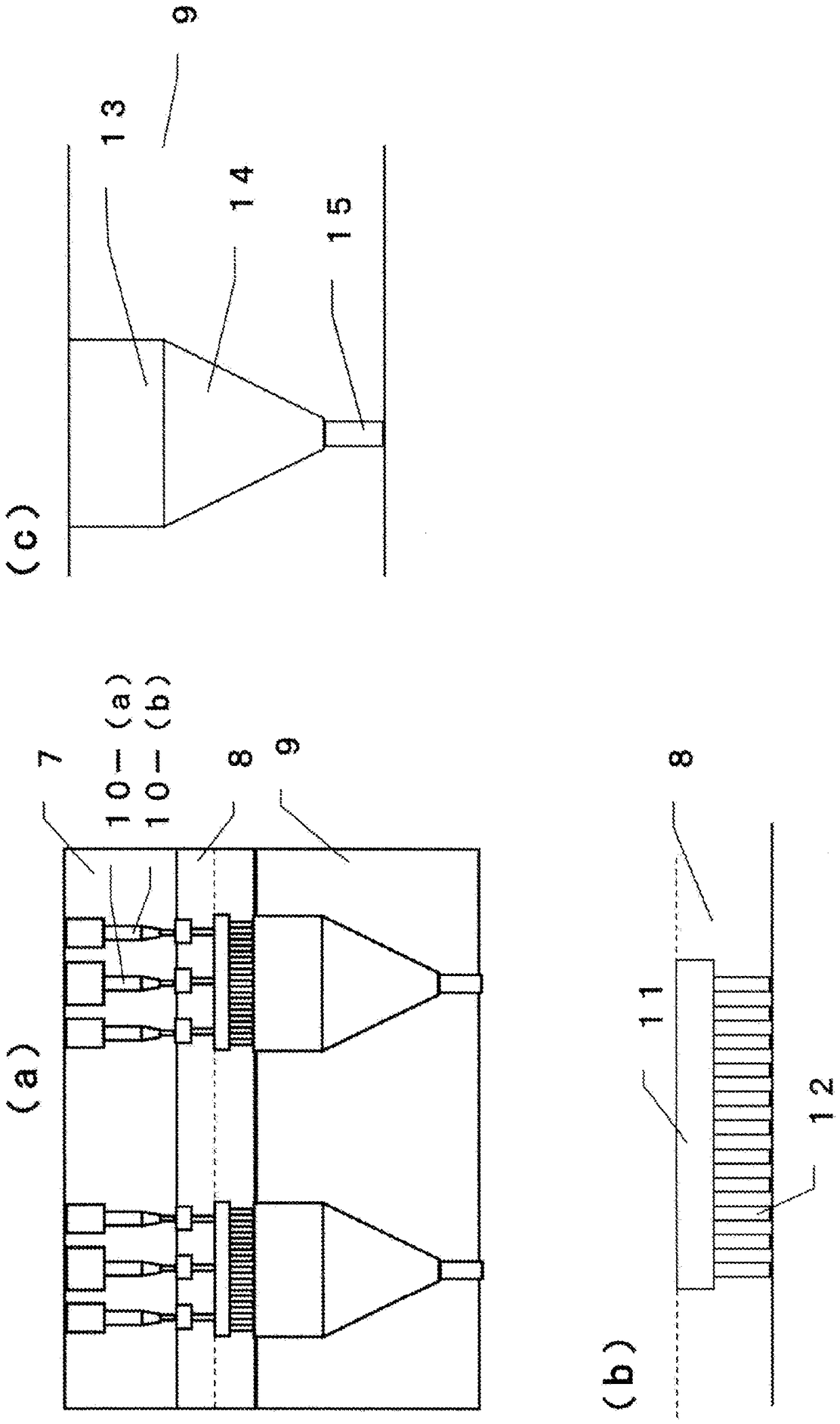

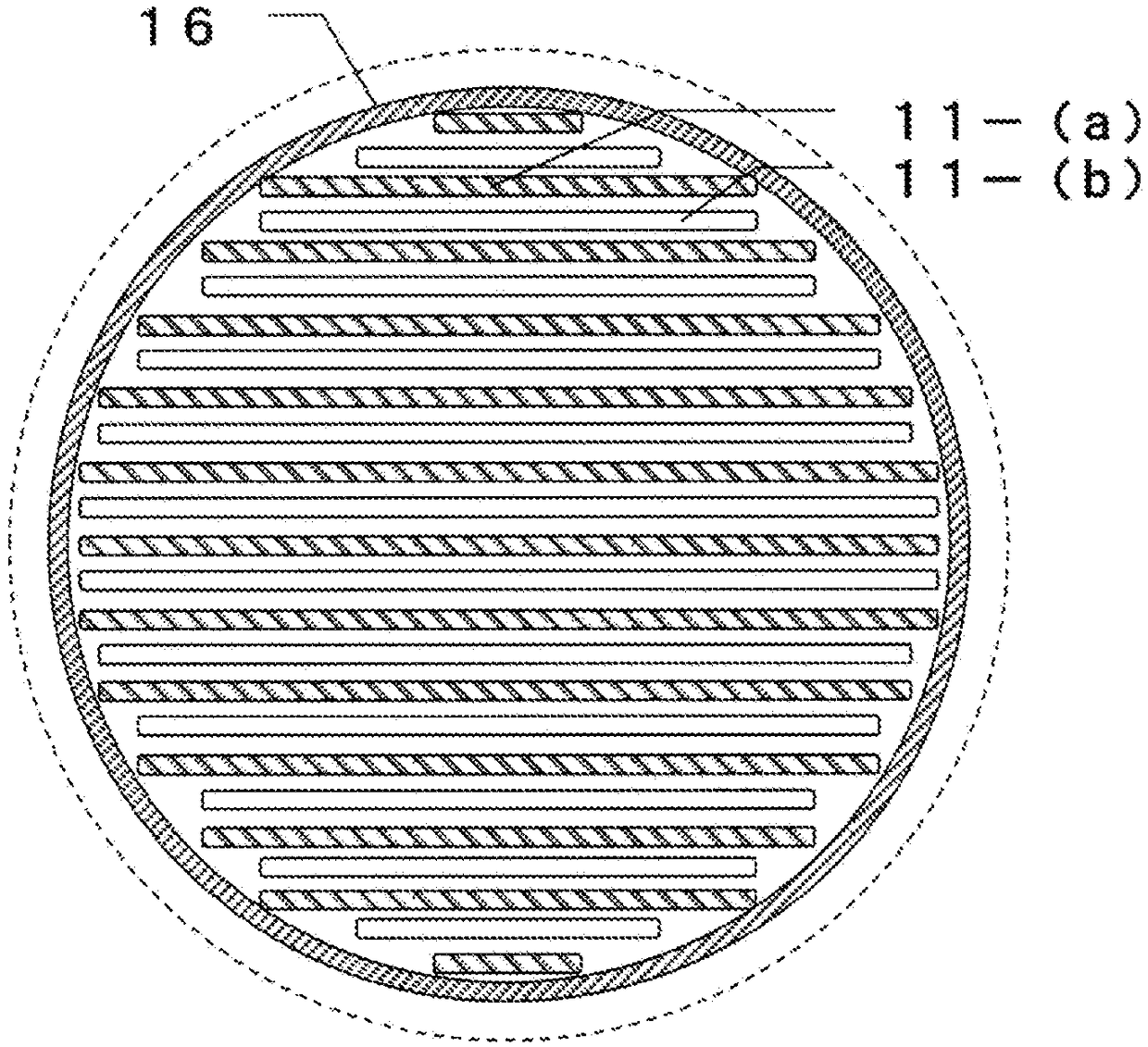

[0145] Polyethylene terephthalate obtained by copolymerizing 30% by weight of polyethylene glycol (PEG6000S manufactured by Sanyo Chemical Industry Co., Ltd.) with a number average molecular weight of 8300 g / mol was used as an island component, and polyethylene terephthalate ( IV=0.66) As the sea component, they were vacuum-dried at 150° C. for 12 hours, and then supplied to an extrusion-type composite spinning machine according to the compounding ratio of 30% by weight of the island component and 70% by weight of the sea component, and they were separately melted, They were then flowed into the assembled figure 2 In the spin pack of the sea-island composite die shown in (a), the composite polymer flow was discharged from the discharge hole at a discharge rate of 25 g / min to obtain a spun sliver. Furthermore, on the distribution plate immediately above the discharge plate, an average of 18 distribution holes per one discharge hole for island components are drilled, and imag...

Embodiment 2~5

[0147] (Examples 2-5), (Comparative Example 1)

[0148]A false twist yarn was produced in the same manner as in Example 1, except that the ratio (T / R) of the outermost layer thickness T to the fiber diameter R was changed as shown in Table 1.

[0149] Table 1 shows the evaluation results of fiber properties and fabric properties of the obtained fibers. In Examples 2 to 5, as T / R becomes larger, the cracks of the sea component are reduced, and the color rendering property is improved. On the other hand, although the hygroscopicity after the hot water treatment becomes low, the hygroscopicity is good. In addition, in any case, the level dyeing property, the quality, and the feeling of dryness were all acceptable levels. On the other hand, in Comparative Example 1, although the color development, level dyeing property, quality, and dry feel were good, the volume swelling of the hygroscopic polymer of the island component was suppressed because of the large T / R. As a result, aft...

Embodiment 6~11

[0157] False twist yarns were produced in the same manner as in Example 1, except that the number and arrangement of island components in the distribution plate of the sea-island composite die described in Example 1 were changed as shown in Table 2.

[0158] Table 2 shows the evaluation results of fiber properties and fabric properties of the obtained fibers. Even when the number and arrangement of the island components are changed, there are few cracks in the sea component, and the hygroscopicity after hot water treatment is good. In addition, the color rendering property is also good, and the level dyeing property, quality, and dry feel are all acceptable levels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com