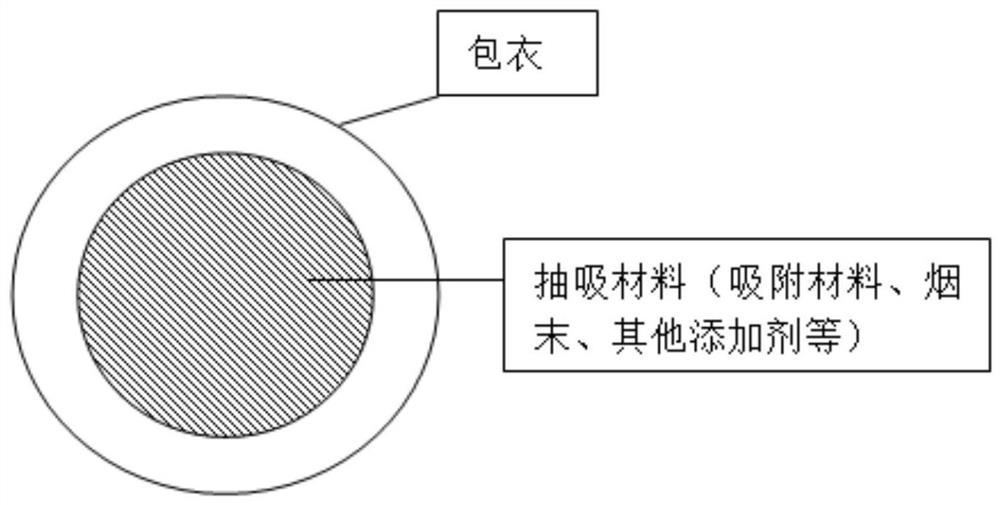

Smoking material for heat-not-burn tobacco products

A heat-not-burn, tobacco product technology, used in tobacco, smoker's products, applications, etc., can solve the problems of poor uniformity, small smoke volume, burning sensation, etc., and achieves simple process, improved utilization, no burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Weigh 50g of 200-mesh original diatomite material, add 60g of starch, silica gel and water in a ratio of 3:3:15, mix and knead evenly. Place in MXX1600-15 box-type high-temperature furnace for calcination. The calcination conditions are as follows: adopt temperature program, the heating rate is 6°C / min, the calcination temperature is 800°C, and the continuous calcination time at 800°C is 40 min. , Sub-sieve to 30 mesh (particle size: 0.6mm) for later use, obtain porous diatomite material, and test its adsorption multiple (note: liquid weight / material weight) to be 0.81.

[0043] Take another 40ml of the mixed solution of the atomizing agent and tobacco extract, put 33g of the 30-mesh diatomite that has been fired before into the solution, mix evenly and fully absorb the solution, and obtain the diatomite adsorption material for use. Separately take starch and 1% sodium carboxymethyl cellulose at a ratio of 10:100 as a binder, add the above-mentioned diatomite adsorption...

Embodiment 2

[0046] Weigh 20g of 200 mesh original diatomite material, add 69g of starch, silica gel, CMC and water, the ratio is 12:6:6:45, mix and knead evenly. Place in MXX1600-15 box-type high-temperature furnace for calcination. The calcination conditions are as follows: adopt temperature program, heating rate 10 ℃ / min, calcination temperature 1000 ℃, 1000 ℃ continuous calcination time is 60 min, after calcination is completed, the temperature is naturally cooled to room temperature, crushed , and sub-sieve to 40 mesh (particle size: 0.45mm) for later use, and obtain the diatomite adsorption material for later use. And test its adsorption ratio (note: liquid weight / material weight) is 1.21.

[0047] Take another 25ml of the mixed solution of atomizing agent, tobacco extract and 0.1% vanillin, put 21g of 40-mesh diatomite that has been fired before into the solution, mix well and fully absorb the solution, and obtain diatomite adsorption material, add 42g spice tobacco powder and 2.2g...

Embodiment 3

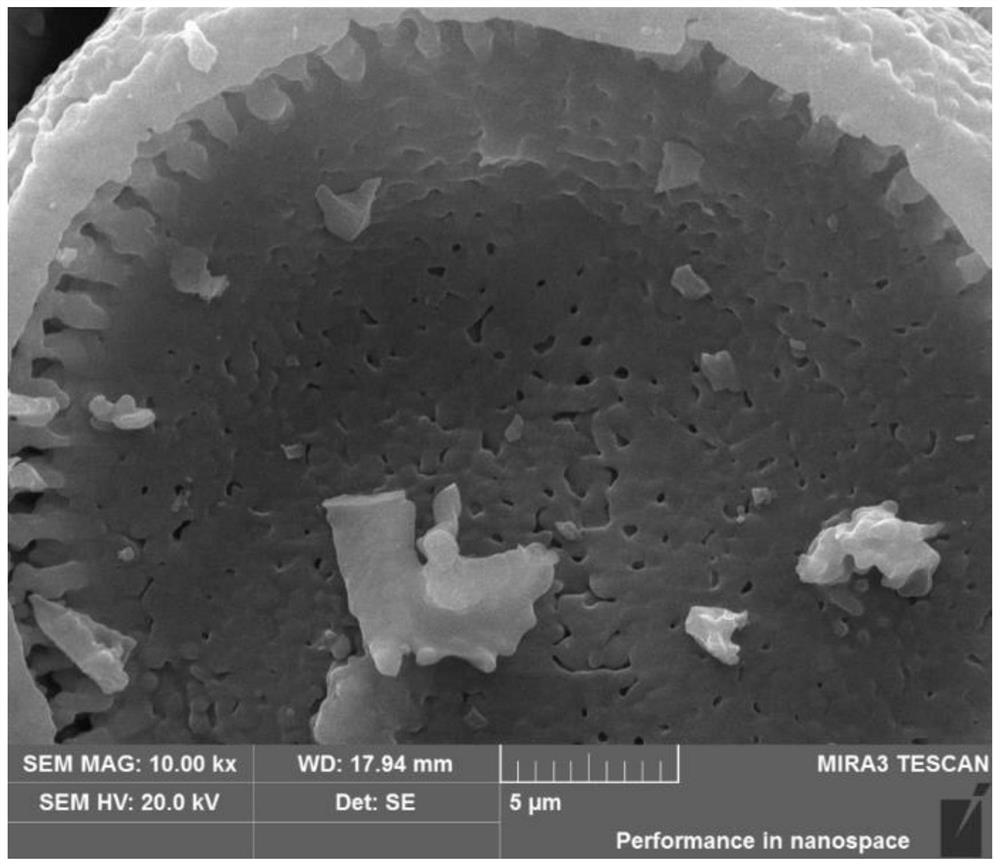

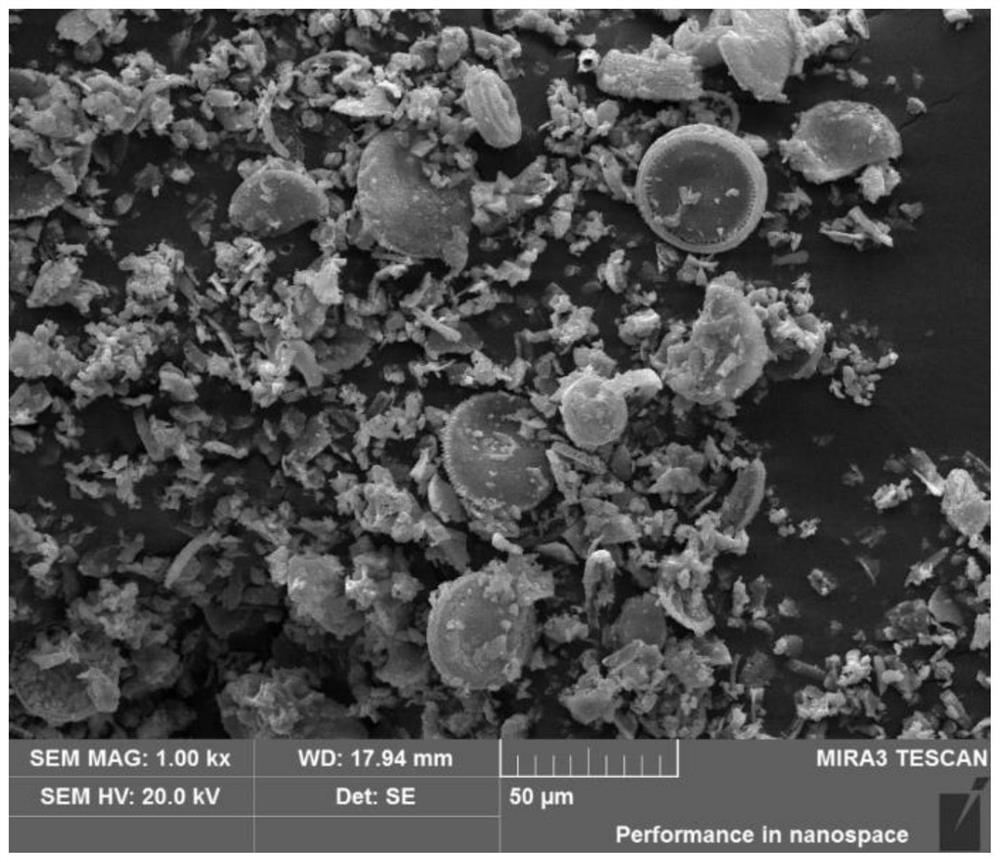

[0050] Weigh 80g of 300-mesh raw diatomite material, add 80g of sodium carboxymethylcellulose, sodium hydroxide and water in a ratio of 4:1:12, mix and knead evenly. Place in MXX1600-15 box-type high-temperature furnace for calcination. The calcination conditions are as follows: adopt temperature program, the heating rate is 12°C / min, the calcination temperature is 900°C, and the continuous calcination time at 900°C is 60 min. , and sub-sieved to 50 mesh (particle size is 0.355mm), to obtain diatomite adsorption material for later use. And test its adsorption multiple (note: liquid weight / material weight) is 1.23. Obtained by scanning electron microscopy Figure 4 , Figure 5 .

[0051] in figure 2 with image 3 It is the original diatomite material that has not been fired, and it can be clearly seen that there is no macropore, and the porosity per unit volume of the material is low. And from Figure 4 with Figure 5 More pores can be clearly seen, and the porosity per ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com