Preparation method and application of photochromic building window capable of blocking ultraviolet light

A photochromic and building technology, applied in building structures, buildings, building components, etc., can solve the problems of high raw material cost, hindering the large-scale development of photochromic building windows, and unable to meet the economics of industrial production, etc. achieve the effect of reducing transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

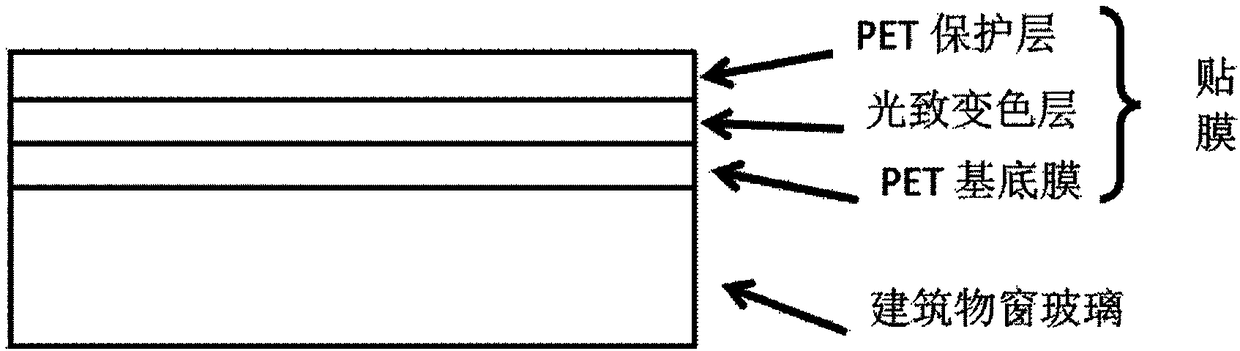

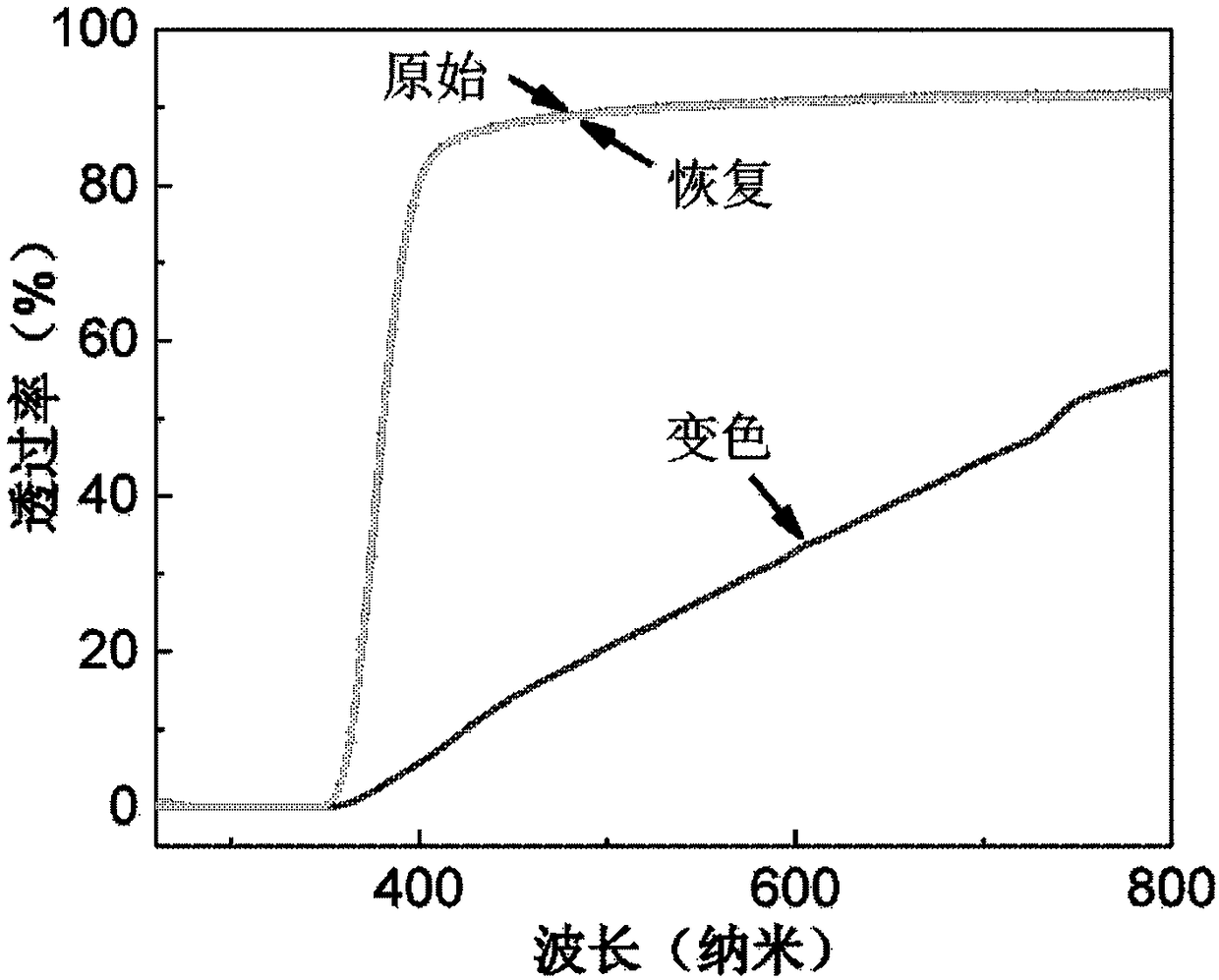

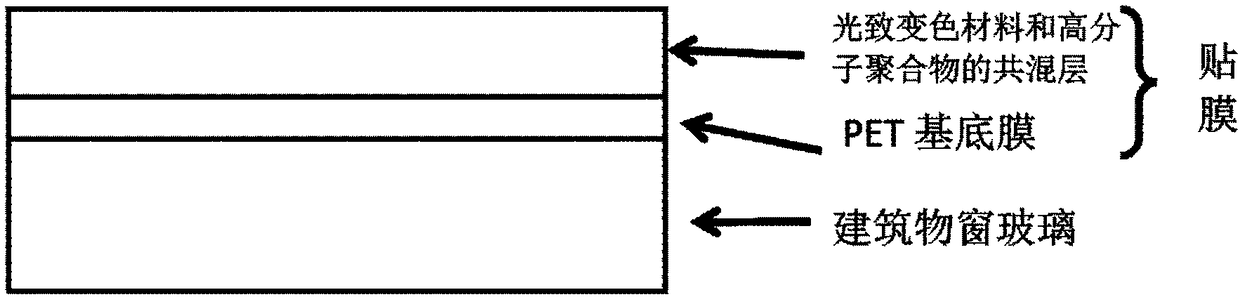

Method used

Image

Examples

Embodiment 1

[0084] Example 1: BiBaO 2 Preparation of Br nanomaterials and film-type photochromic building windows

[0085] Weigh 0.5g of bismuth nitrate into a 50mL three-neck flask filled with 30mL of deionized water, and stir for 5 minutes with a magnetic stirrer; weigh 1g of mannitol into the above mixture, and heat to 100°C with an electric heating mantle; Weigh 0.6g of barium acetate and add to the above mixture, continue to heat and stir for 10 minutes; weigh 1g of disodium ethylenediaminetetraacetate and add to the above mixture, continue to heat and stir for 30 minutes until the solution becomes transparent to obtain the first solution;

[0086] Weigh 0.45g of sodium bromide and add it into a beaker with a volume of 25mL containing 10mL of deionized water, and stir for 15 minutes with a magnetic stirrer equipped with an electric heating mantle until the solution becomes transparent to obtain the second solution;

[0087] Inject the second solution into the first solution with a s...

Embodiment 2

[0093] Example 2: Sb 4 o 5 Cl 2 Preparation of nanomaterials and preparation of film-type photochromic building windows

[0094] Weigh 0.8g of antimony chloride and add it into a three-neck flask with a volume of 50mL containing 30mL of deionized water, and stir for 5 minutes with a magnetic stirrer; weigh 0.5g of xylitol and add it to the above mixture, and heat it with an electric heating mantle to 150°C; weigh 1g of polyvinylpyrrolidone and add it to the above mixture, continue heating and stirring for 15 minutes until the solution becomes transparent, and obtain the first solution;

[0095] Weigh 0.2g of sodium chloride and add it into a beaker with a volume of 10mL containing 3mL of oleic acid, and stir for 25 minutes with a magnetic stirrer equipped with an electric heating mantle until the solution appears transparent to obtain the second solution;

[0096] Inject the second solution into the first solution with a syringe, and react for 80 seconds in the three-neck f...

Embodiment 3

[0101] Example 3: Bi 2 o 3 WO 3 Fabrication of nanomaterials Fabrication of integrated photochromic building windows

[0102]Weigh 0.5g of bismuth nitrate and add it into a three-neck flask with a volume of 50mL containing 30mL of deionized water, and stir for 5 minutes with a magnetic stirrer; weigh 0.5g of mannitol and add it to the above mixture, and heat it to 90°C with an electric heating mantle Weighing 0.8g cetyltrimethylammonium bromide was added to the above mixed solution, and continued heating and stirring for 30 minutes until the solution was transparent to obtain the first solution;

[0103] Weigh 0.2g of sodium tungstate and add it to a 10mL beaker containing 5mL of deionized water, and stir for 15 minutes with a magnetic stirrer equipped with an electric heating mantle until the solution becomes transparent to obtain the second solution;

[0104] Inject the second solution into the first solution with a syringe, and react for 240 seconds in the three-neck fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com