Preparation method of flexible transparent conducting thin film

A transparent conductive film, flexible technology, applied in the direction of cable/conductor manufacturing, conductive layer on the insulating carrier, circuit, etc., can solve the problem of poor adhesion between the film and the substrate, achieve no pollution to the ecological environment, high production efficiency, broaden the The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

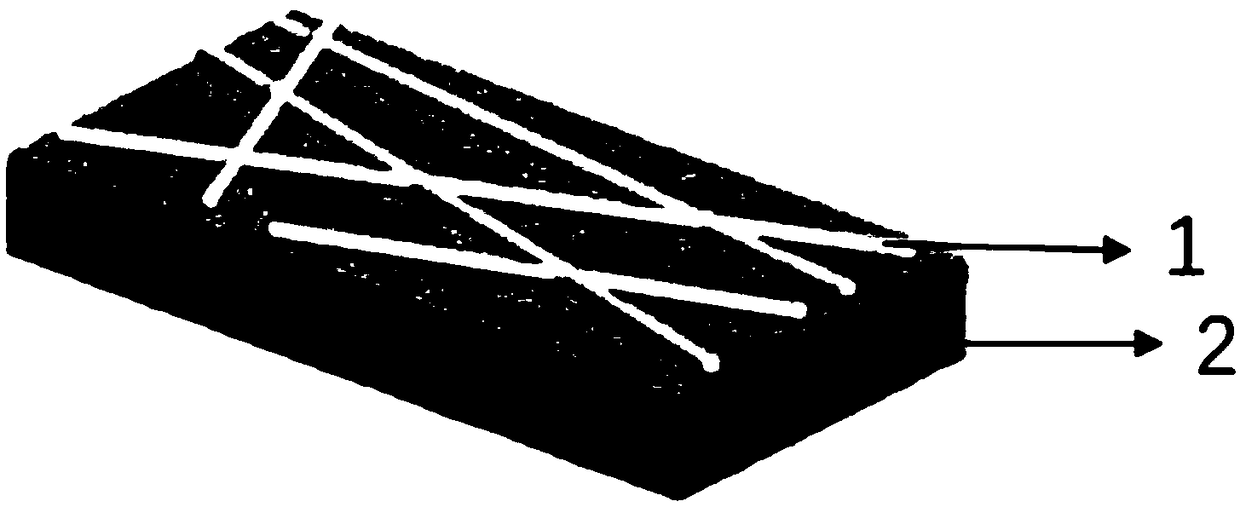

[0030] The process of preparing flexible base transparent conductive film in this embodiment is as follows: image 3 As shown, it specifically includes the following steps:

[0031] Step A, providing a PET film with a clean surface, the specific steps include:

[0032] A1, clean the PET film with acetone for 30 minutes under ultrasonic conditions, take it out and rinse the surface of the PET film with deionized water;

[0033] A2, the PET film obtained in step A1 was cleaned with ethanol for 30 min in the ultrasonic state, and dried naturally.

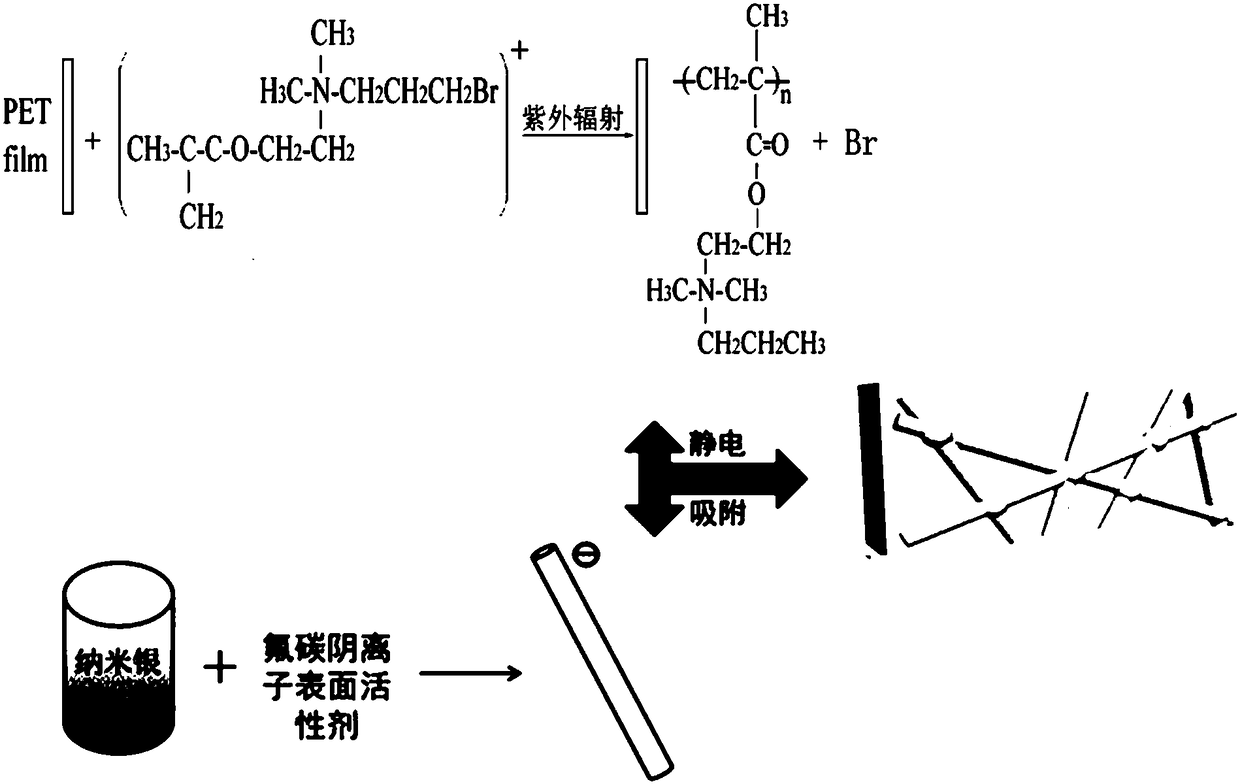

[0034] In step B, the PET film obtained in step A is irradiated with ultraviolet light, and the surface is grafted with methacryloxyethyl dimethyl propyl ammonium bromide.

[0035] Step C, adding an anionic surfactant to the nano-silver wire dispersion liquid, and ultrasonically dispersing, the specific process includes the following steps C1-C3:

[0036] Step C1, centrifuging and cleaning the nano-silver wires prepared in the labor...

Embodiment 2

[0046] Step A, providing a PET film with a clean surface, the specific steps include:

[0047] A1, clean the PET film with acetone for 30 minutes under ultrasonic conditions, take it out and rinse the surface of the PET film with deionized water;

[0048] A2, the PET film obtained in step A1 was cleaned with ethanol for 30 min in the ultrasonic state, and dried naturally.

[0049] Step B, grafting methacryloyloxyethyl dimethyl propyl ammonium bromide on the surface of the PET film obtained in step A by chemical grafting method.

[0050] Step C, adding an anionic surfactant to the nano-silver wire dispersion liquid, and ultrasonically dispersing, the specific steps include,

[0051] Step C1, centrifuging and cleaning the nano-silver wire made in the laboratory to remove polyvinylpyrrolidone (PVP) adsorbed on the silver wire to obtain pure nano-silver wire, wherein the nano-silver wire has a diameter of 40-70 nm and a length of 10-20 μm;

[0052]Step C2, disperse the pure nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com