Deep ultraviolet semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of low P-type doping efficiency, low efficiency of ultraviolet LED, low efficiency, etc., to reduce the turn-on voltage, reduce the barrier barrier, The effect of lowering the resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In view of the deficiencies in the prior art, the inventor of this case was able to propose the technical solution of the present invention after long-term research and extensive practice. The technical solution, its implementation process and principle will be further explained as follows. However, it should be understood that within the scope of the present invention, each technical feature of the present invention and each technical feature specifically described in the following (such as an embodiment) can be combined with each other to form a new or preferred technical solution. Due to space limitations, we will not repeat them here.

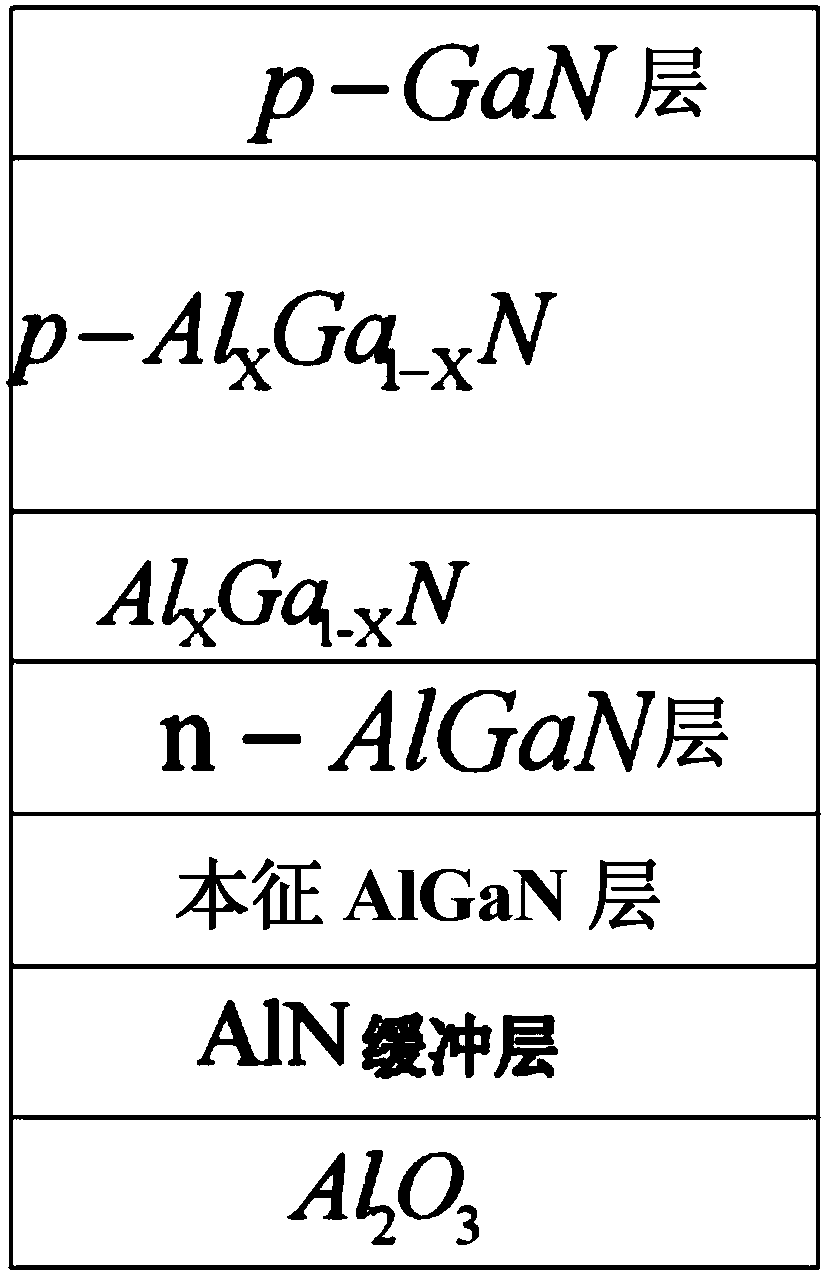

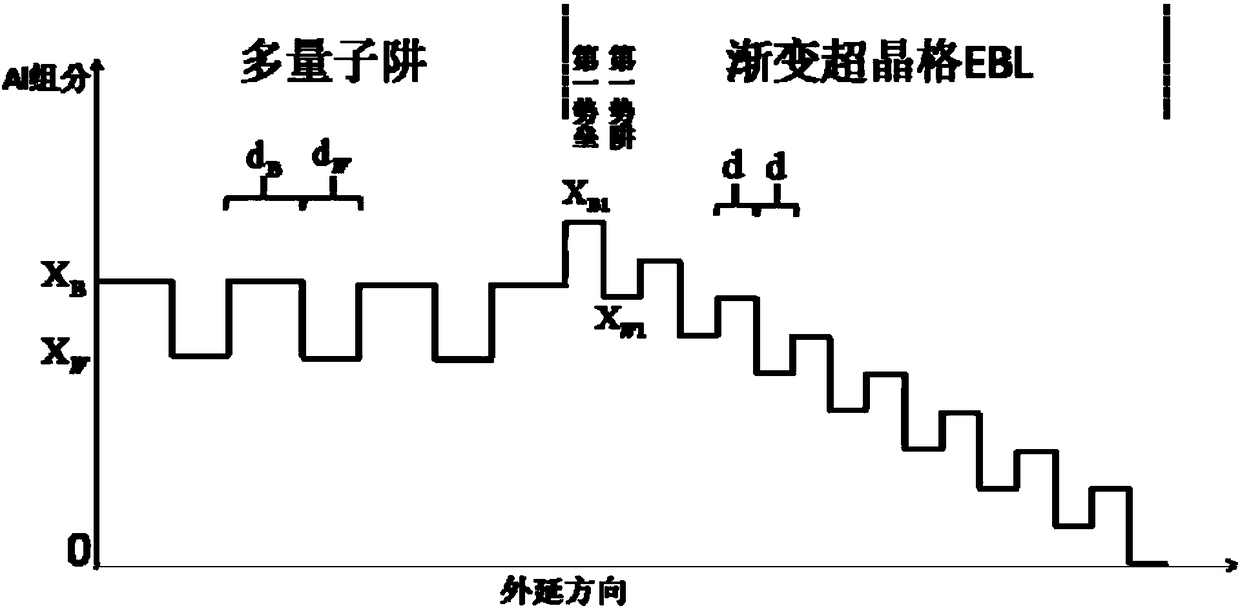

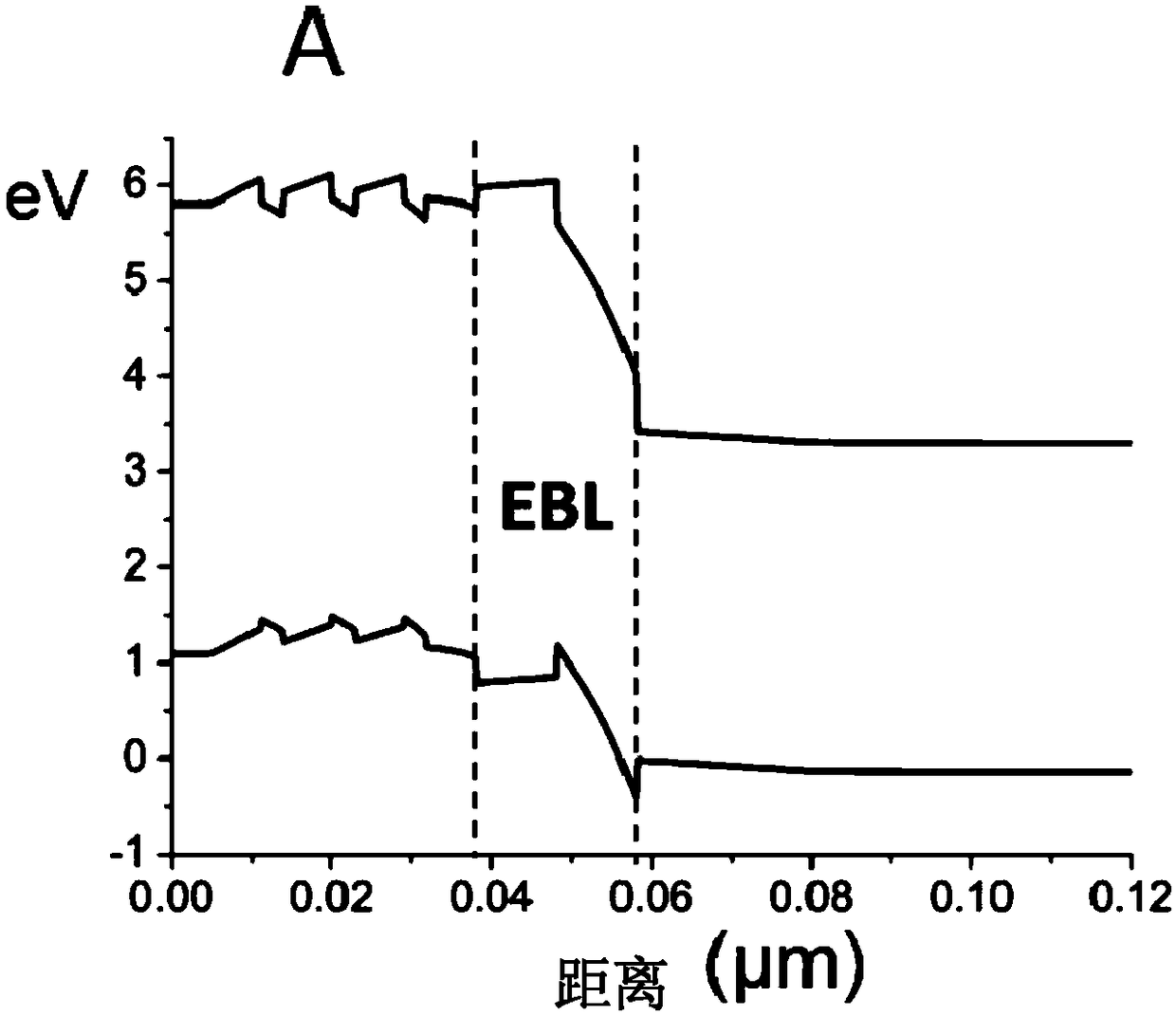

[0027] One aspect of the embodiments of the present invention provides a deep ultraviolet semiconductor device, including an n-type AlGaN layer, a multi-quantum well structure (MQW), an electron blocking layer (EBL) and a p-type GaN layer arranged in sequence along a set direction, so that The electron blocking layer comprises p-typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com