Production process of instant pellet feed for suckling pigs

A production process and pellet feed technology, which is applied to the production process of instant-type suckling pig pellet feed, can solve the problems of large workload, uneven nutrition, easy precipitation, etc., so as to reduce weaning stress and nutritional diarrhea, and improve digestion. rate and feed conversion rate, the effect of improving the absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

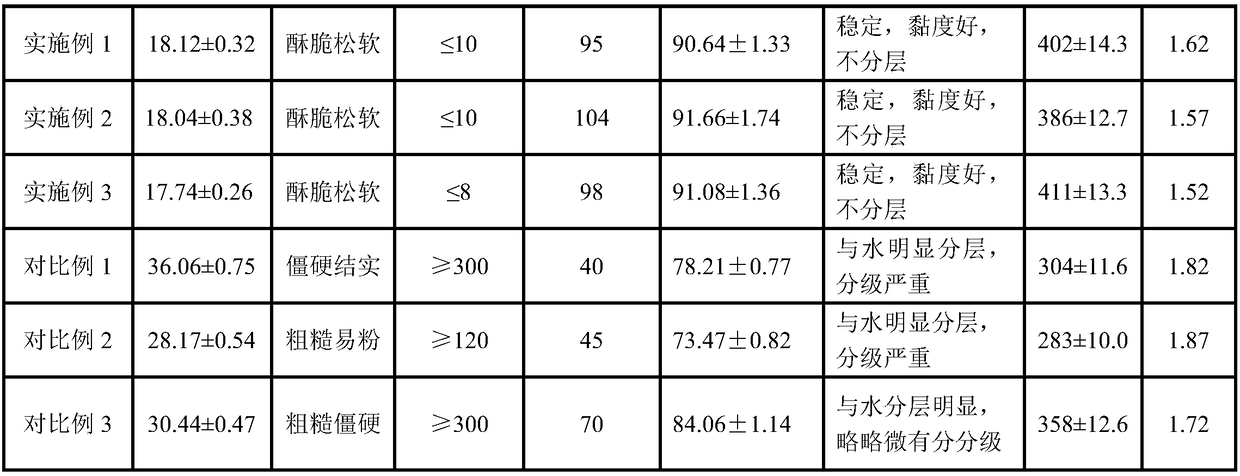

Embodiment 1

[0025] An instant pellet feed for suckling pigs, comprising the following components by weight:

[0026] 840 parts of mixed puffed product of soybean meal and corn, 18 parts of calcium hydrogen phosphate, 4 parts of glucose, 86 parts of fish meal, 12 parts of feed grade calcium carbonate, 40 parts of premix.

[0027] The preparation method of described a kind of instant type suckling pig pellet feed is as follows:

[0028] (1) Soybean meal and corn are crushed separately, and the size of the crushing sieve is 2.0 mm. The crushed soybean meal powder and corn flour are evenly mixed according to the weight ratio of 33:67 to obtain component A;

[0029] (2) Component A undergoes high-temperature puffing, wherein the puffing modulation temperature is 92°C, equipped with three-stage puffing chambers, the first-stage temperature is 95°C, the second-stage is 110°C, and the third-stage is 130°C; the puffing time is 30s, and the puffing die hole The hole diameter is 12 mm, the number o...

Embodiment 2

[0037] An instant pellet feed for suckling pigs, comprising the following components by weight:

[0038] 840 parts of mixed puffed product of soybean meal and corn, 18 parts of calcium hydrogen phosphate, 4 parts of glucose, 86 parts of fish meal, 12 parts of feed grade calcium carbonate, 40 parts of premix.

[0039] The preparation method of described a kind of instant type suckling pig pellet feed is as follows:

[0040] (1) Soybean meal and corn are crushed separately, and the size of the crushing sieve is 2 mm. The crushed soybean meal powder and corn flour are evenly mixed according to the weight ratio of 33:67 to obtain component A;

[0041] (2) Component A undergoes high-temperature puffing, wherein the puffing modulation temperature is 95°C, equipped with three-stage puffing chambers, the first-stage temperature is 100°C, the second-stage is 115°C, and the third-stage is 135°C; the puffing time is 35s, and the puffing die hole The hole diameter is 12 mm, the number of...

Embodiment 3

[0049] An instant pellet feed for suckling pigs, comprising the following components by weight:

[0050] 840 parts of mixed puffed product of soybean meal and corn, 18 parts of calcium hydrogen phosphate, 4 parts of glucose, 86 parts of fish meal, 12 parts of feed grade calcium carbonate, 40 parts of premix.

[0051] The preparation method of described a kind of instant type suckling pig pellet feed is as follows:

[0052] (1) soybean meal and corn are crushed separately, and the size of the crushing sieve is 2 mm, and the crushed soybean meal powder and corn flour are evenly mixed according to the weight ratio of 33:67 to obtain component A;

[0053] (2) Component A undergoes high-temperature puffing, wherein the puffing modulation temperature is 95°C, equipped with three-stage puffing chambers, the first-stage temperature is 100°C, the second-stage is 120°C, and the third-stage is 140°C; the puffing time is 40s, and the puffing die hole The hole diameter is 12mm, the number o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com