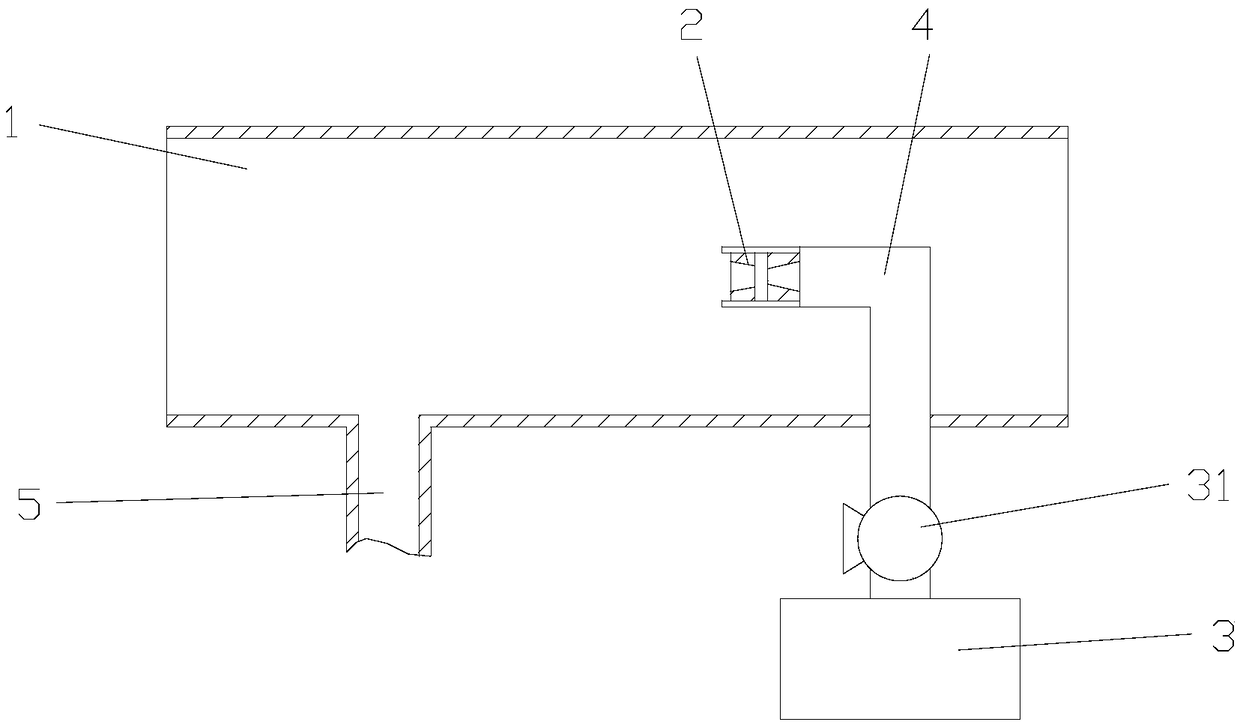

Desulfurization dust-removal pipeline with mixing shower nozzle

A technology for desulfurization and dust removal and nozzles, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators, etc., can solve the problems of low desulfurization and dust removal efficiency, and achieve the goal of improving desulfurization and dust removal efficiency, increasing contact area, and improving output accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

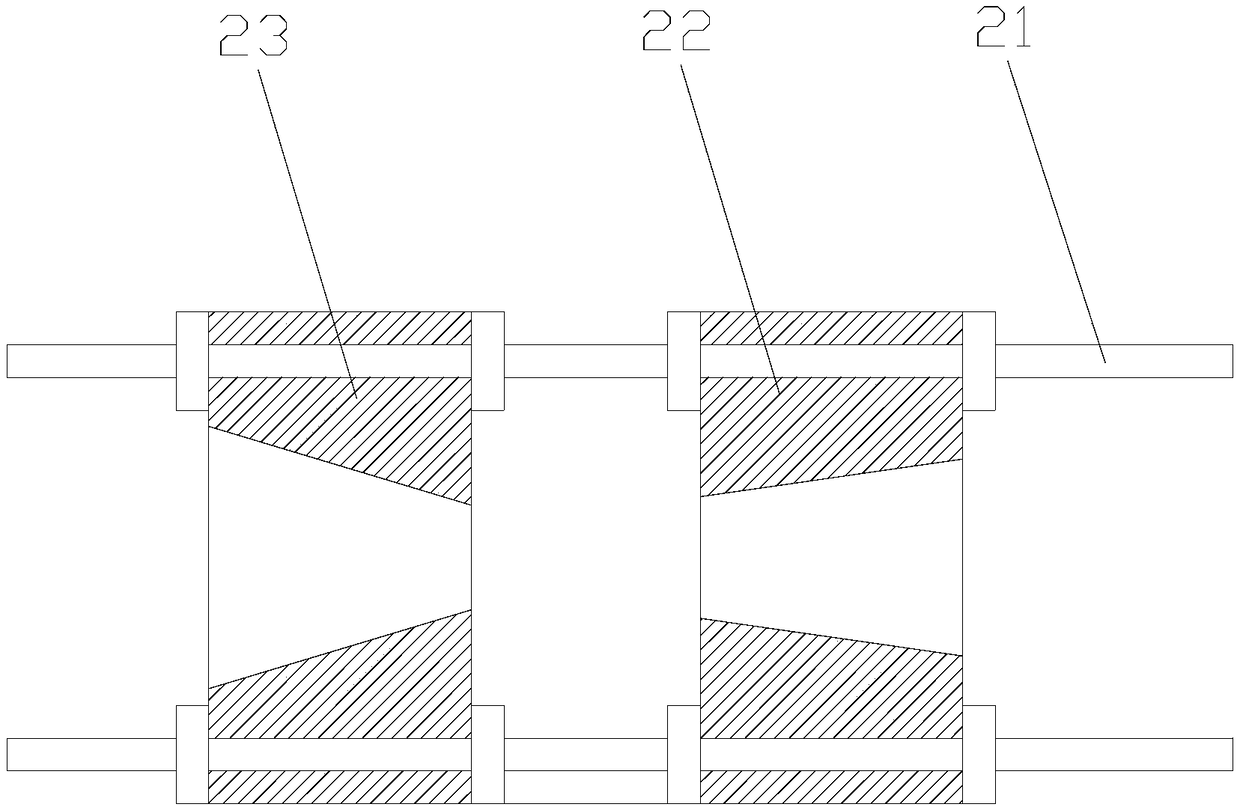

[0082]In the present embodiment, the nozzle holder 21 in the mixing nozzle 2 selects 4 studs, and the diameter of the cutting screw is 20mm; the outer diameter of the first nozzle 22 is 150mm, the length is 80mm, and the inner diameter of the entrance is D 1 =80mm, the inner diameter of the outlet is D 2 =32mm; the outer diameter of the second nozzle 23 is 150mm, the length is 70mm, and the inner diameter of the entrance is D 3 =34mm, the inner diameter of the outlet is D 4 =45mm, and a spiral nozzle is installed at the outlet of the second shower head 23; the gap between the first shower head 22 and the second shower head 23 is 80mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com