A Method for Controlling the Shape of Irregular Bubbles in Microchannels

A technology of bubble shape and microchannel, applied in the direction of mixing methods, chemical instruments and methods, mixers, etc., can solve problems such as few researches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] At room temperature (20±5°C), first prepare 50 g of CTAB aqueous solution with a concentration of 0.02 mmol / L and stir for 3 minutes to disperse CTAB evenly in water; finally add 30% silica nano The particle dispersion is stirred for 5 minutes and ultrasonically dispersed for 1 minute to fully dissolve; a compound system is obtained, and the mass fraction of silica nanoparticles in the compound system is 2%.

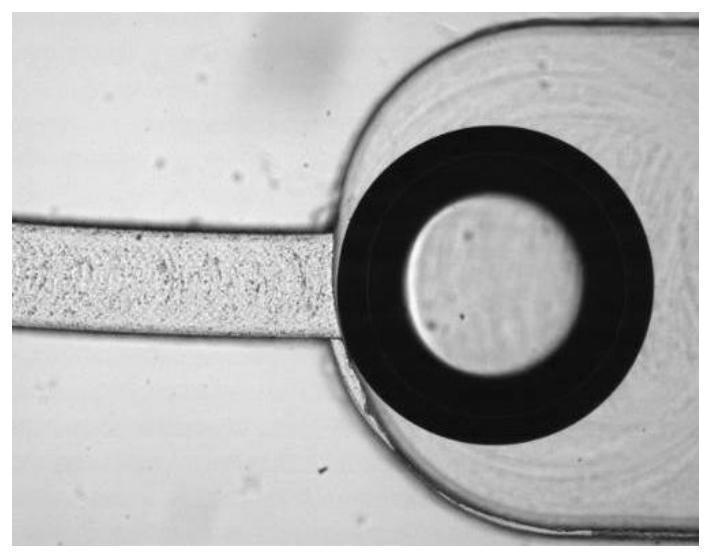

[0052] The compound system is used as the continuous phase to inject from the liquid phase inlet 5 using a micro injection pump, and the injection speed is 0.45ml / min, and methane is injected from the gas phase inlet 6 using a micro injection pump as the dispersed phase, and the injection speed is 0.45ml / min , wait for the stable generation of bubbles at the cross-shaped place formed by two liquid phase channels 1, one gas phase channel 2 and one mixing channel 4, and observe the change of the shape of the bubbles in the control tube 3. Depend on figure 2 It can...

Embodiment 2

[0054] At room temperature (20±5°C), first prepare 50 g of CTAB aqueous solution with a concentration of 0.07 mmol / L and stir for 3 minutes to disperse CTAB evenly in water; finally add 30% silica nano The particle dispersion is stirred for 5 minutes and ultrasonically dispersed for 1 minute to fully dissolve; a compound system is obtained, and the mass fraction of silica nanoparticles in the compound system is 2%.

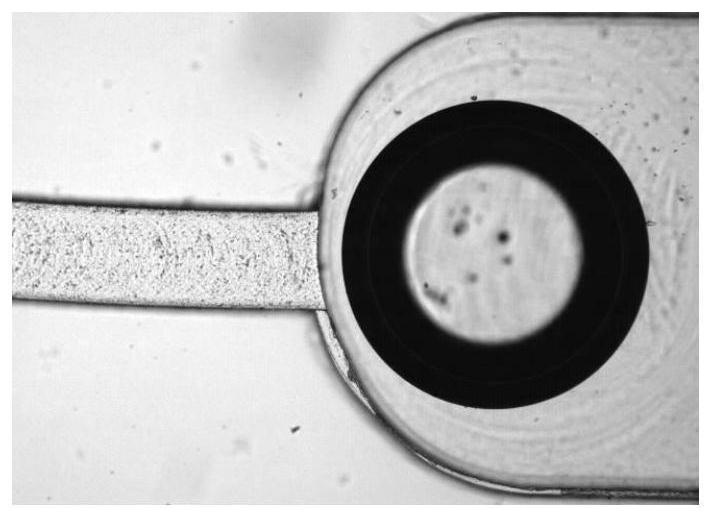

[0055] The composite system is used as the continuous phase to inject from the liquid phase inlet 5 with a micro-injection pump at an injection rate of 0.45ml / min, and carbon dioxide is injected as a dispersed phase from the gas-phase inlet 6 with a micro-injection pump at an injection rate of 0.45ml / min , wait for the stable generation of bubbles at the cross-shaped place formed by two liquid phase channels 1, one gas phase channel 2 and one mixing channel 4, and observe the change of the shape of the bubbles in the control tube 3. Depend on image 3 It can be s...

Embodiment 3

[0057] At room temperature (20±5°C), first prepare 50 g of CTAB aqueous solution with a substance concentration of 0.1 mmol / L, stir for 3 minutes to disperse CTAB evenly in water; finally add 30% silica nano The particle dispersion is stirred for 5 minutes and ultrasonically dispersed for 1 minute to fully dissolve; a compound system is obtained, and the mass fraction of silica nanoparticles in the compound system is 2%.

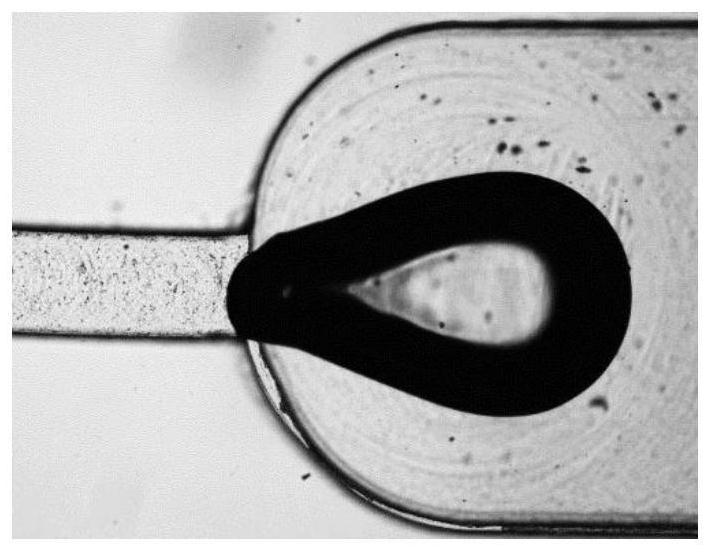

[0058] Use the compound system as the continuous phase to inject from the liquid phase inlet 5 with a micro-injection pump at an injection rate of 0.45ml / min, and use nitrogen as the dispersed phase to inject from the gas-phase inlet 6 with a micro-injection pump at an injection rate of 0.45ml / min , wait for the stable generation of bubbles at the cross-shaped place formed by two liquid phase channels 1, one gas phase channel 2 and one mixing channel 4, and observe the change of the shape of the bubbles in the control tube 3. Depend on Figure 4 It can be s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com