Method for preparing porous alginic acid noble metal adsorbent through template method

A technology of alginic acid and precious metals, applied in alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of inability to deal with mixed metal ion solutions, limit industrial application and promotion, etc., and achieve excellent selective adsorption effect , good practical application prospects, and the effect of improving the adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

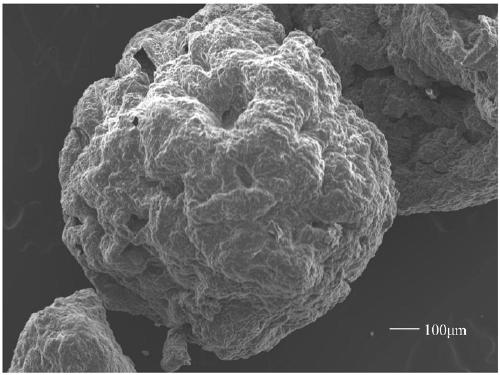

Embodiment 1

[0024] Add 10 mL of carbon disulfide into 250 mL of 14% sodium hydroxide solution, then add 5 g of sodium alginate powder, stir until completely dissolved, and keep at 20°C for 12 hours. Add 2.0g of alumina powder to the solution, stir it rapidly with a mechanical stirrer for 90s, and place the solution in an ultrasonic cleaner to remove air bubbles. The resulting solution was added dropwise through a syringe (20Gauge needle) into a calcium chloride solution with a mass concentration of 2% to solidify into a ball, left to stand for 12 hours, filtered out the prepared hydrogel, and transferred to a hydrochloric acid solution with pH=1 to remove Alumina formwork, rinsed repeatedly. Finally, the porous alginic acid noble metal adsorbent was obtained by drying at room temperature.

Embodiment 2

[0026] Add 10 mL of carbon disulfide to 250 mL of 14% sodium hydroxide solution, then add 8 g of sodium alginate powder, stir until completely dissolved, and keep at 30°C for 12 hours. Add 4.0g of alumina powder to the solution, stir rapidly with a mechanical stirrer for 120s, and place the solution in an ultrasonic cleaner to remove air bubbles. The resulting solution was added dropwise through a syringe (16Gauge needle) into a calcium chloride solution with a mass concentration of 1% to solidify into a ball, left to stand for 12 hours, filtered out the prepared hydrogel, and transferred to a hydrochloric acid solution of pH=1 to remove Alumina formwork, rinsed repeatedly. Finally, the porous alginic acid noble metal adsorbent was obtained by drying at room temperature.

Embodiment 3

[0028] Add 10 mL of carbon disulfide to 250 mL of 14% sodium hydroxide solution, then add 10 g of sodium alginate powder, stir until completely dissolved, and keep at 30°C for 12 hours. Add 4.0g of alumina powder to the solution, stir rapidly with a mechanical stirrer for 120s, and place the solution in an ultrasonic cleaner to remove air bubbles. The resulting solution was added dropwise through a syringe (16Gauge needle) into a calcium chloride solution with a mass concentration of 2% to solidify into a ball, left to stand for 12 hours, filtered out the prepared hydrogel, and transferred to a hydrochloric acid solution of pH=1 to remove Alumina formwork, rinsed repeatedly. Finally, the porous alginic acid noble metal adsorbent was obtained by drying at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com