Flexible graphene heating fabric with real-time temperature monitoring function

A flexible graphite and graphene technology, used in the fields of clothing, physiotherapy products, and protective gear, can solve the problems of difficult clothing combination and heavy fabrics, and achieve the effects of easy precise control, fast heating, and uniform heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

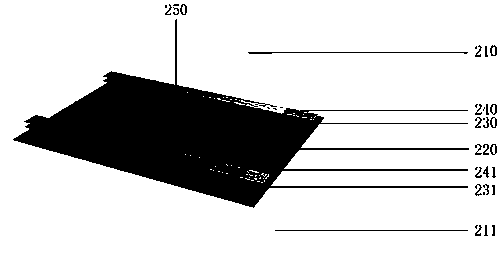

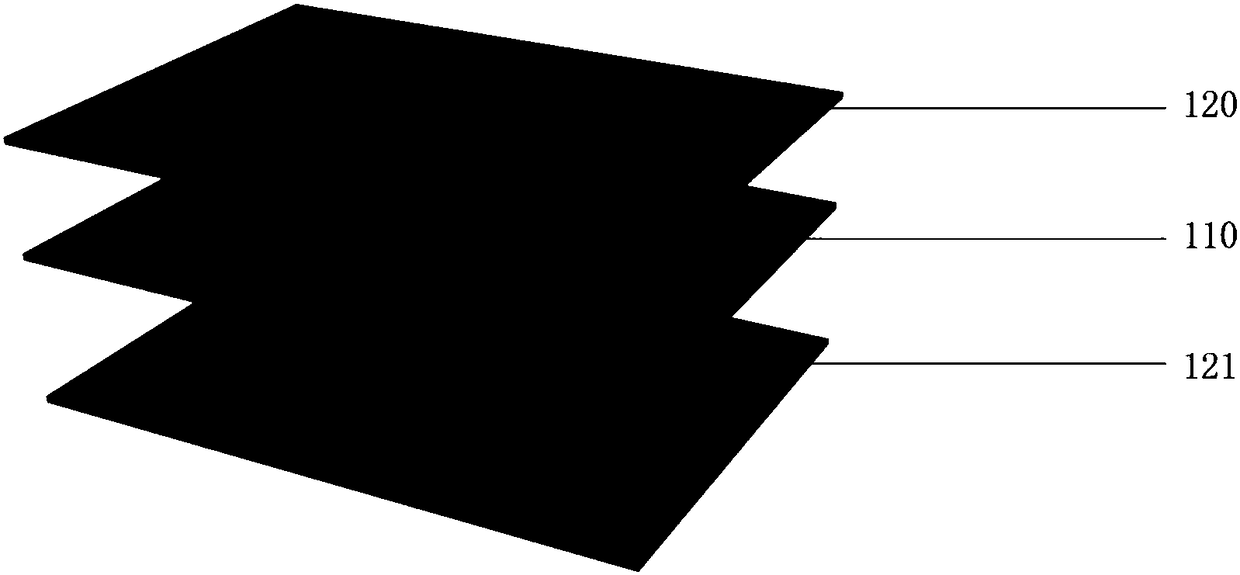

[0033] see figure 1 , as shown in the figure, the flexible graphene heating fabric includes a heating temperature measurement layer 110 and insulation layers 120 and 121 on both sides of the heating temperature measurement layer.

[0034] The schematic diagram of the structure of heating temperature measurement is as follows: figure 2 shown. The heating temperature measurement layer has only one heating unit. The heating and temperature measuring layer 200 includes flexible polymer substrates 210 and 211 , a low-resistance graphene conductive layer 220 , conductive silver paste films 230 and 231 , copper foils 240 and 241 , and a printable flexible temperature sensor 250 . Wherein the flexible polymer substrates 210 and 211 are PE films. The low-resistance graphene conductive layer 220 is printed on the flexible polymer substrate 211 by using graphene-based water-based conductive ink by screen printing, and the dry film thickness of the low-resistance graphene conductive l...

Embodiment 2

[0039] The flexible graphene heating fabric provided in this embodiment has a similar structure and is divided into three layers, such as figure 1 As shown, it includes a thermal temperature measurement layer 110 and thermal insulation layers 120 and 121 on both sides of the heating temperature measurement layer.

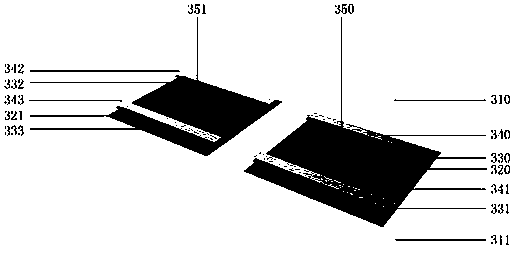

[0040] The schematic diagram of the structure of heating temperature measurement is as follows: image 3shown. The heating and temperature measuring layer 300 includes flexible polymer substrates 310 and 311 , low-resistance graphene conductive layers 320 and 321 and two heating and temperature measuring units. The two heating and temperature measuring units include conductive silver paste films 330 , 331 , 332 and 333 , copper foils 340 , 341 , 342 and 343 , and printable flexible temperature sensors 350 and 351 . Wherein the flexible polymer substrates 310 and 311 are PET film and PN film respectively. The low-resistance graphene conductive layers 320 and 321 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com