Flower-like Y-shaped hexagonal ferrite-manganese dioxide nano-powder and preparation method thereof

A technology of hexagonal ferrite and nano-powder, applied in chemical instruments and methods, manganese oxide/hydroxide, nanotechnology and other directions, can solve the problems of difficult synthesis of Y powder, complex crystal structure, etc. The effect of reflection, large specific surface area, and high reflection loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

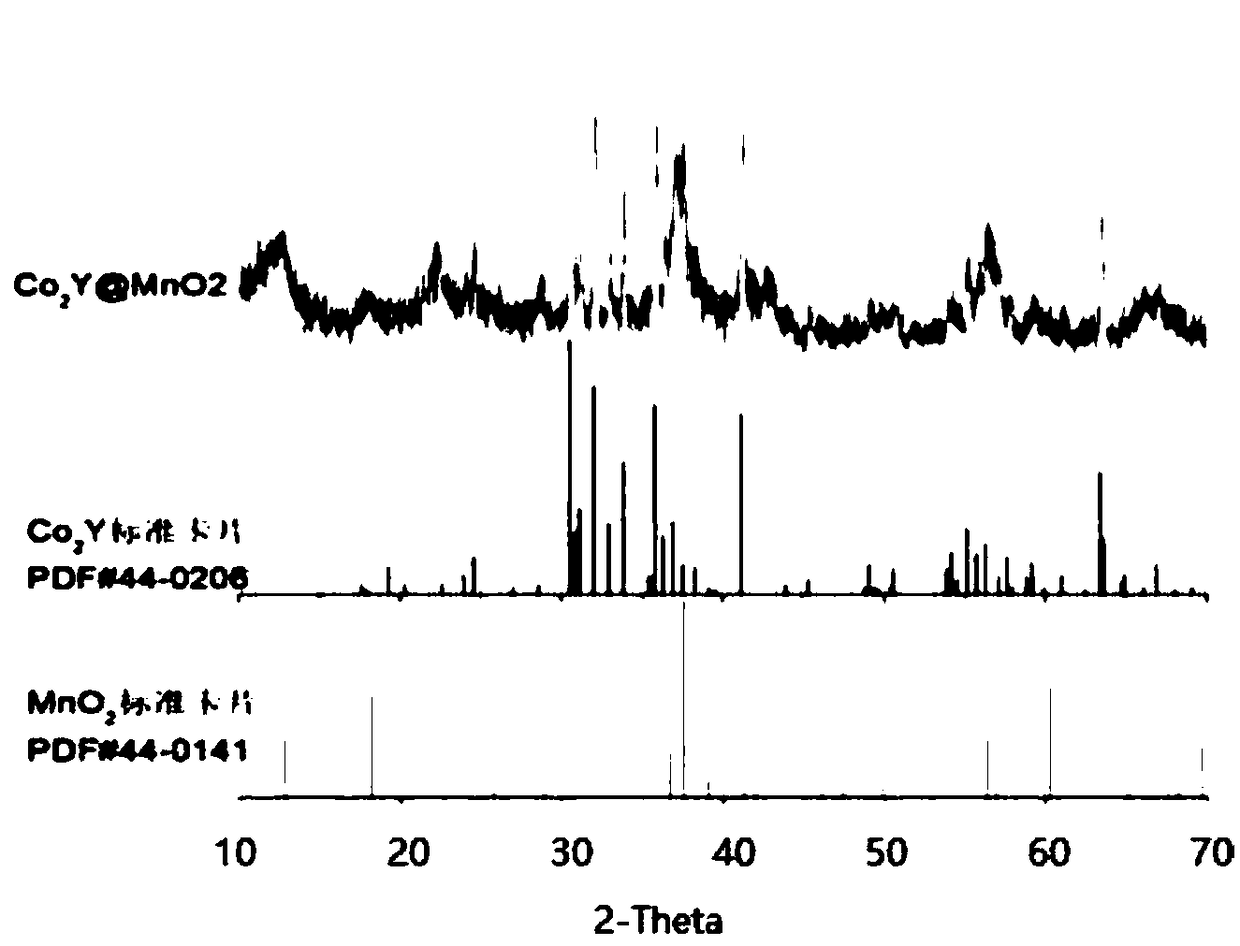

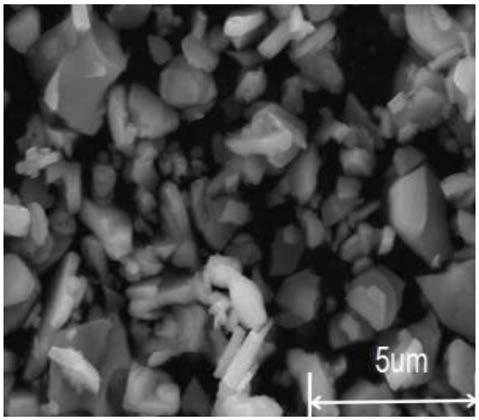

[0074] A flower-shaped Co of the present invention 2 Y-MnO 2 The preparation method of nanopowder specifically implements according to the following steps:

[0075] Step 1, prepare Ba by solid-phase method 2 co 2 Fe 12 o 22 (Co 2 Y) powder, specifically:

[0076] In step 1.1, pure grade BaCO will be analyzed 3 , CoO, Fe 2 o 3 Mix with absolute ethanol evenly to obtain a precursor mixture, then add zirconium balls to the precursor mixture for ball milling for 1 hour, and then dry at 100°C for 3 hours to obtain a solid mixture;

[0077] BaCO 3 , CoO, Fe 2 o 3 The stoichiometric ratio is 1:1:6, BaCO 3 , CoO, Fe 2 o 3 The mass ratio of total mass to absolute ethanol and zirconium balls is 5:4:10;

[0078] The diameter of the zirconium ball is 2mm;

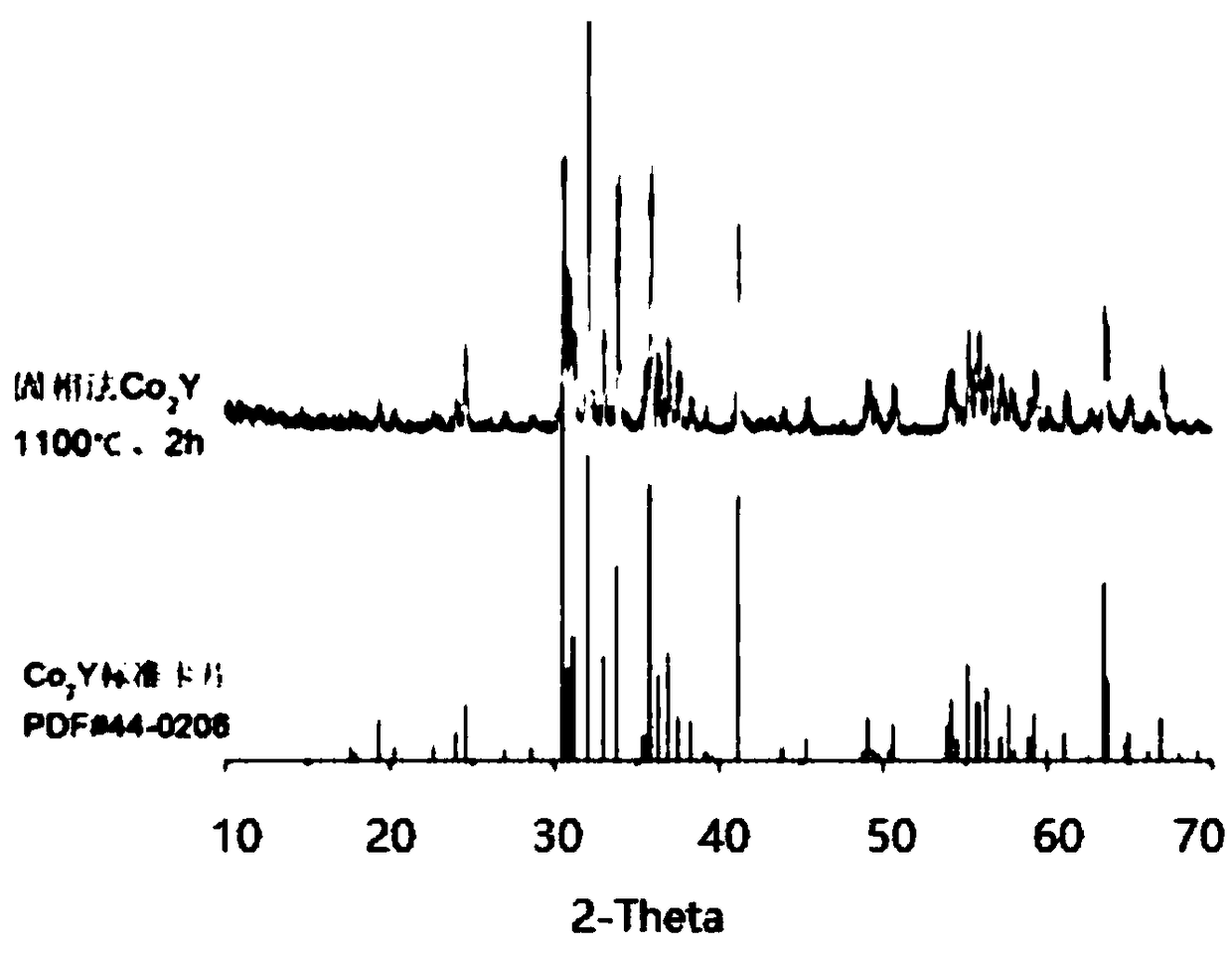

[0079] Step 1.2, calcining the solid mixture obtained after step 1.1, and cooling with the furnace to obtain a mixed powder;

[0080] The calcination temperature is 1100°C, and the calcination time is 2h;

[0081] Step...

Embodiment 2

[0095] A flower-shaped Co of the present invention 2 Y-MnO 2 The preparation method of nanopowder specifically implements according to the following steps:

[0096] Step 1, prepare Ba by solid-phase method 2 co 2 Fe 12 o 22 (Co 2 Y) powder, specifically:

[0097] In step 1.1, pure grade BaCO will be analyzed 3 , CoO, Fe 2 o 3 Mix well with absolute ethanol to obtain a precursor mixture, then add zirconium balls to the precursor mixture for ball milling for 1.5 hours, and then dry at 110°C for 4 hours to obtain a solid mixture;

[0098] BaCO 3 , CoO, Fe 2 o 3 The stoichiometric ratio is 1:1:6, BaCO 3 , CoO, Fe 2 o 3 The mass ratio of total mass to absolute ethanol and zirconium balls is 5:4:10;

[0099] The diameter of the zirconium ball is 2mm;

[0100] Step 1.2, calcining the solid mixture obtained after step 1.1, and cooling with the furnace to obtain a mixed powder;

[0101] The calcination temperature is 1150°C, and the calcination time is 2h;

[0102] S...

Embodiment 3

[0116] A flower-shaped Co of the present invention 2 Y-MnO 2 The preparation method of nanopowder specifically implements according to the following steps:

[0117] Step 1, prepare Ba by solid-phase method 2 co 2 Fe 12 o 22 (Co 2 Y) powder, specifically:

[0118] In step 1.1, pure grade BaCO will be analyzed 3 , CoO, Fe 2 o 3 Mix well with absolute ethanol to obtain a precursor mixed solution, then add zirconium balls to the precursor mixed solution for ball milling, the ball milling time is 2 hours, and then dry at 110°C for 5 hours to obtain a solid mixture;

[0119] BaCO 3 , CoO, Fe 2 o 3 The stoichiometric ratio is 1:1:6, BaCO 3 , CoO, Fe 2 o 3 The mass ratio of total mass to absolute ethanol and zirconium balls is 5:4:10;

[0120] The diameter of the zirconium ball is 2mm;

[0121] Step 1.2, calcining the solid mixture obtained after step 1.1, and cooling with the furnace to obtain a mixed powder;

[0122] The calcination temperature is 1100°C, and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap