Alkali-activated gelling material with low alkali dissolution rate cured at room temperature and preparation method thereof

A technology of normal temperature curing and cementitious materials, which is applied in the direction of cement production, etc. It can solve the problems of slag falling, unsuccessful plastering, and the decrease of the bonding force between plastering mortar and material matrix, so as to achieve the improvement of compressive strength and flexural strength , compressive strength and flexural strength improvement, the effect of restricting the migration of alkali metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also proposes a method for preparing the aforementioned alkali-activated gelling material with low alkali dissolution rate maintained at normal temperature, which comprises the following steps: 1) weighing the powder raw material and water glass respectively; 2) taking the powder The raw materials are uniformly mixed to obtain a gelled powder; 3) the gelled powder and water glass are mixed with water to obtain a slurry of an alkali-activated gelled material; 4) the slurry is molded and maintained at room temperature.

[0037] Preferably, in the aforementioned method for preparing an alkali-activated gelling material with low alkali dissolution rate cured at room temperature, the water-cement ratio of the slurry is 0.5 in parts by mass.

[0038] The alkali-activated gelling material has a fast setting time and can be prepared immediately after use.

[0039] The alkali-activated gelling material can be cured at normal temperature to achieve the requi...

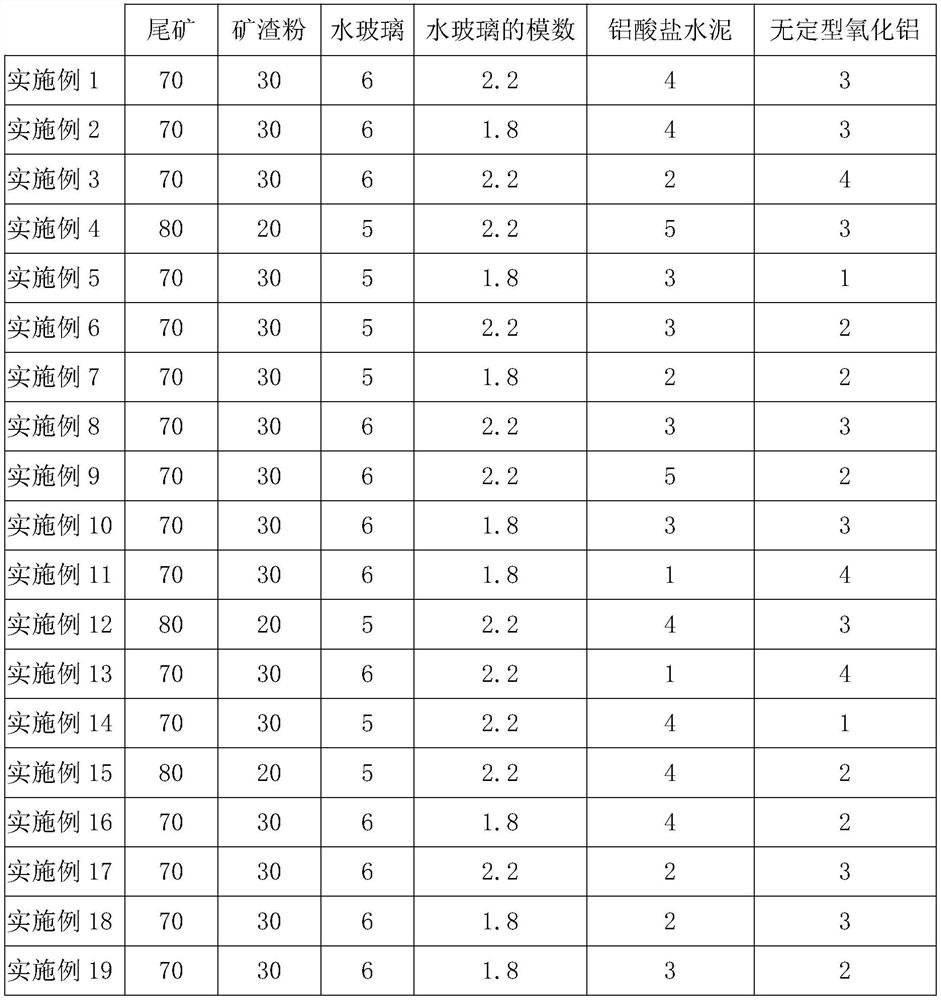

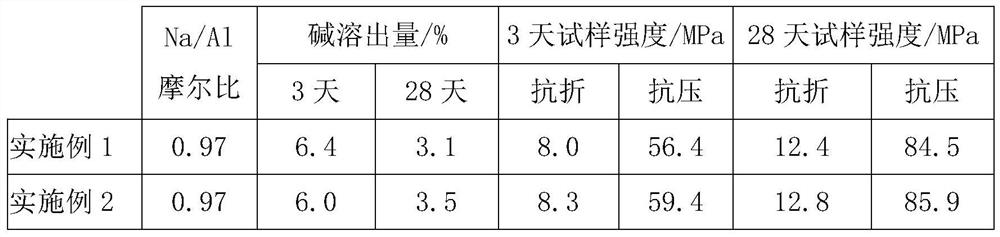

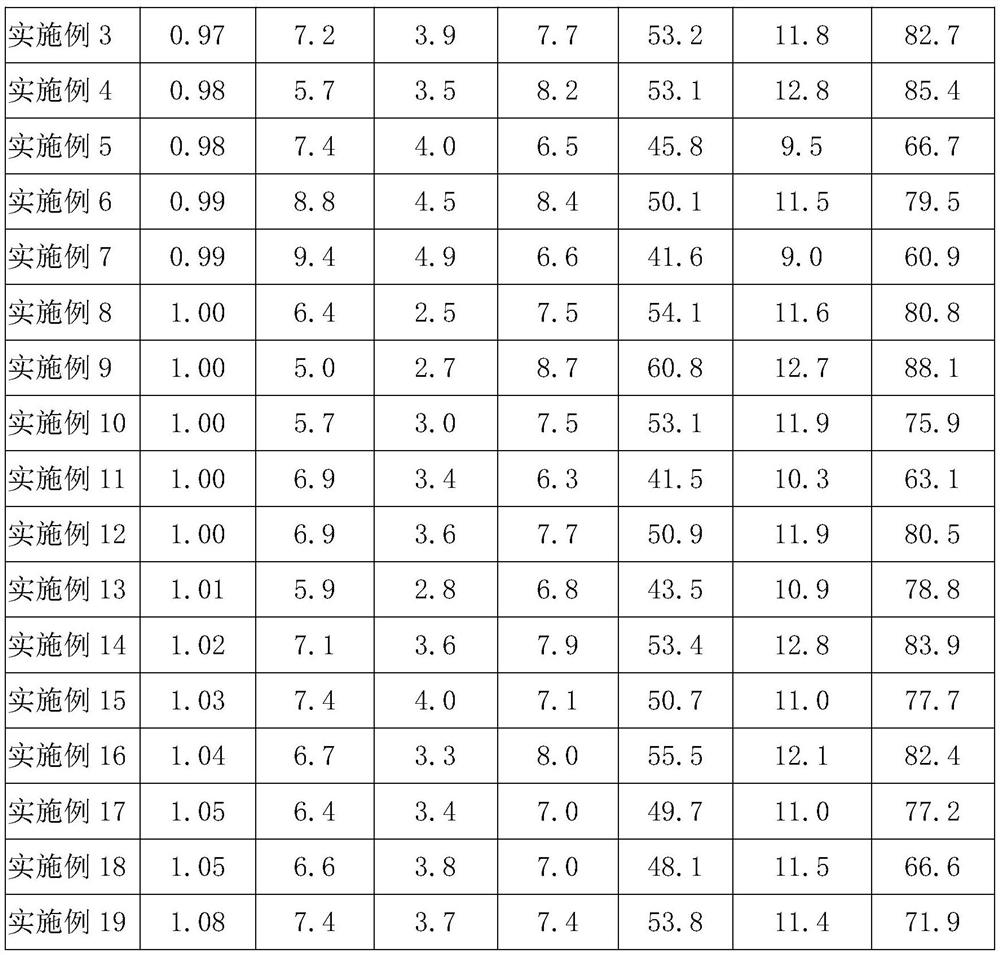

Embodiment 1-19

[0048] According to the formula shown in Table 1, the alkali-activated gelling material of the low alkali dissolution rate of normal temperature curing is prepared, and the steps are as follows: 1) weigh tailings, slag powder and water glass according to the above-mentioned formula table; The raw materials described above are mixed uniformly to obtain gelled powder; 3) the described gelled powder is mixed with water glass and water, and the quality of adding water is "(tailings quality+slag powder quality+aluminate cement quality+amorphous alumina quality)×0.5-the quality of water in water glass ", obtain the slurry of alkali-activated gelling material; Wherein, the quality of water in water glass is the quality of water in the aqueous solution of water glass, and its amount can be By the water glass dosage described in above-mentioned table 1 and obtain according to its solid content, modulus calculation; Wherein, modulus is that the water glass solution solid content of 1.8 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com