Method for producing high-quality slag powder based on desulfurized gypsum

A technology of desulfurized gypsum and slag powder, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of poor fluidity, which is only suitable for belt transportation, and high water content, so as to improve energy consumption indicators and improve performance , the effect of enhancing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

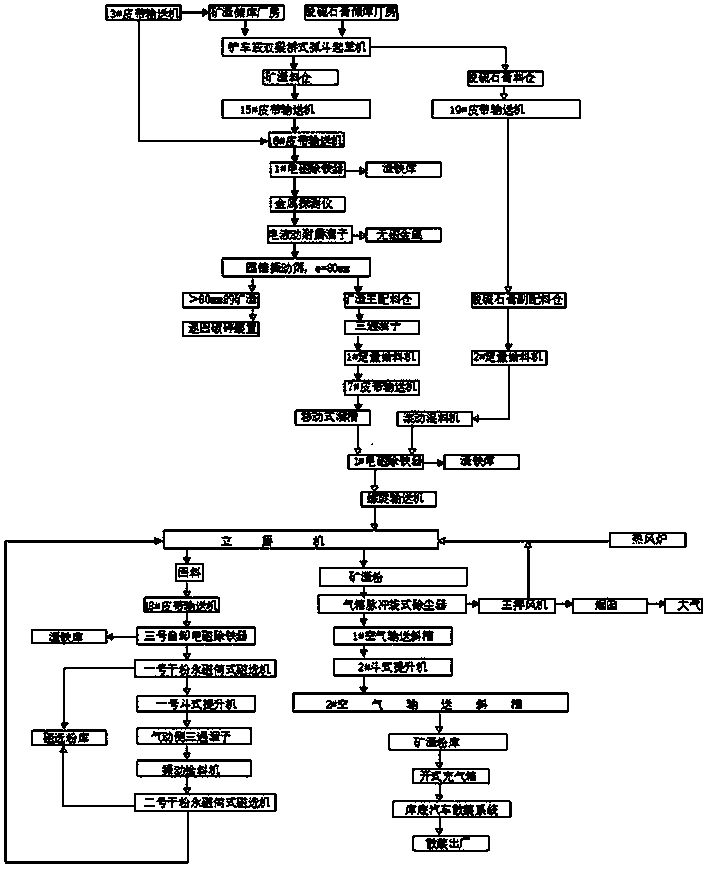

[0034] This embodiment is based on the method for producing high-quality slag powder from desulfurized gypsum, such as figure 1 Shown, this production method comprises the steps:

[0035]Step S1: Slag metal removal pretreatment: The slag stored in the mixed storage workshop is grabbed by a 20T driving grab bucket into the slag bin, and then transferred to the No. 16 belt conveyor outside the mixed storage workshop by the No. 15 belt conveyor. Go through the No. 1 self-unloading electromagnetic iron remover to remove iron once, and then enter the electro-hydraulic wear-resistant slide to remove non-magnetic metal once after being detected by the metal detector, and then pass through the cone vibrating screen to crush the unbroken slag and vibrate the cone The aperture of the sieve is 80mm, and the slag with a particle size of less than 80mm is screened out and enters the slag main batching bin. The slag with a particle size of ≥80mm is sent to the stockpile from the vibrating s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com